Split type anti-rolling type double-freedom-degree lug

A degree of freedom, split-type technology, applied in the field of electromechanical servo systems, can solve the problems of anti-rolling, limit, anti-rotation and easy wear of lugs, and achieve the effects of simplifying manufacturing, reducing gaps, and improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In addition to the embodiments described below, the present invention may also have other embodiments or be practiced in different ways. Therefore, it should be understood that the invention is not limited to the details of construction of the components described in the following specification or illustrated in the accompanying drawings. While only one embodiment is described herein, the claims are not limited to that embodiment.

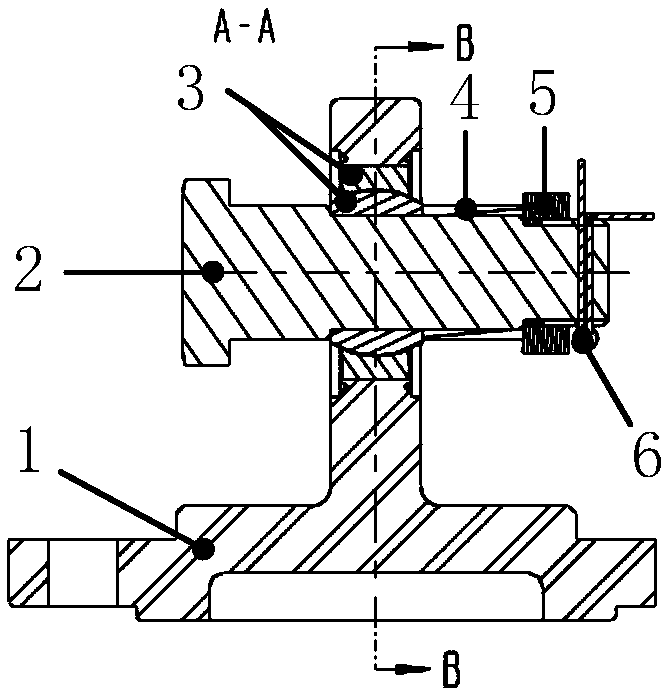

[0023] The present invention is a split type anti-rolling type double degree of freedom lug, such as figure 1 , figure 2 , image 3 As shown, it includes a single support lug 1, a limit anti-rotation block 7, a positioning pin 8, a fastening screw 9 and a spring washer 10; the limit anti-rotation block 7 and the single support lug 1 are positioned through the positioning pin 8, and successively Install the spring washer 10 and the fastening screw 9 to fasten the connection;

[0024] The double-degree-of-freedom support lug also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com