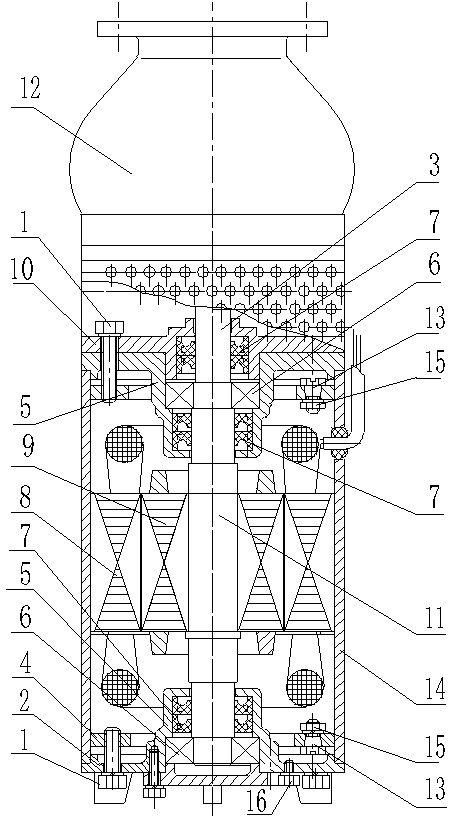

Submersible electric pump convenient to machine and assembly and high in assembly efficiency

A technology of submersible electric pump and assembly efficiency, which is applied to the components, pumps, and pump devices of pumping devices for elastic fluids, and can solve the problems of uneven bearing end cover size, low degree of generalization of assembly, and complicated processing. , to achieve the effect of good assembly effect, improved appearance quality and simple assembly process

- Summary

- Abstract

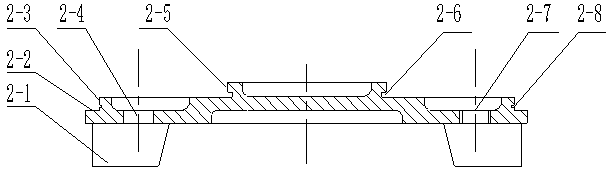

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

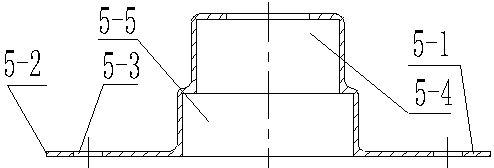

[0079] Embodiment 2: the tapered bolts are tapered bolts with slotted heads.

[0080] The head slotted tapered bolt includes: a tapered head opening slot 4-11, a tapered head rod 4-12 and a screw rod 4-13; one end of the head slotted tapered bolt is a tapered head rod 4-12, There is a taper head opening groove 4-11 on the end face of the taper head rod 4-12; the other end of the head slotted tapered bolt is a screw rod 4-13.

[0081] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com