Tangential force engine and core assemblies thereof

A core component and engine technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as low fuel efficiency, low thermal efficiency, complex engine structure, etc., and achieve high fuel efficiency, high thermal efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description is only for disclosing the present invention to enable those skilled in the art to practice the present invention. The embodiments in the following description are only examples, and those skilled in the art can think of other obvious modifications. The basic principles of the invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and others without departing from the spirit and scope of the invention.

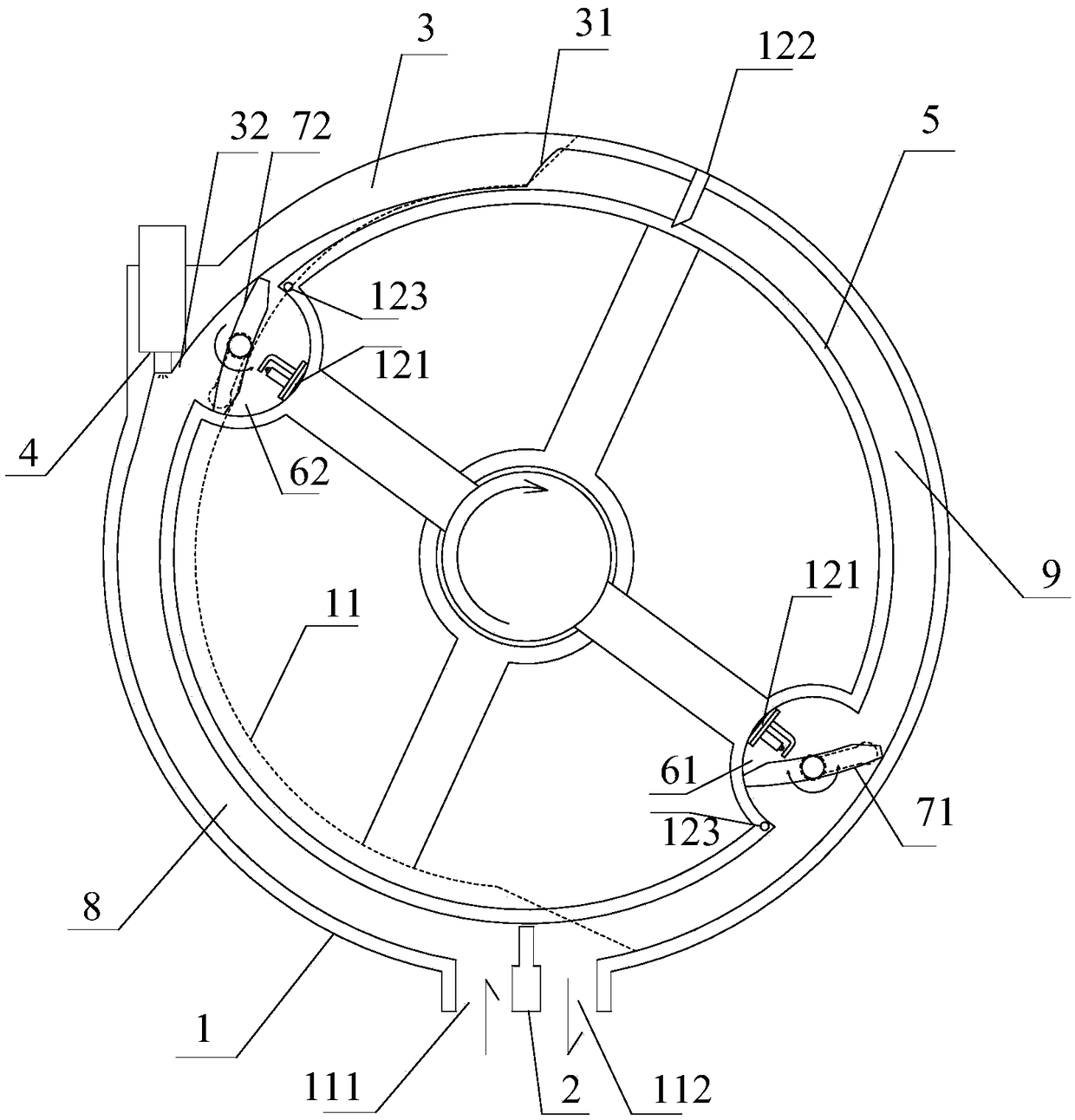

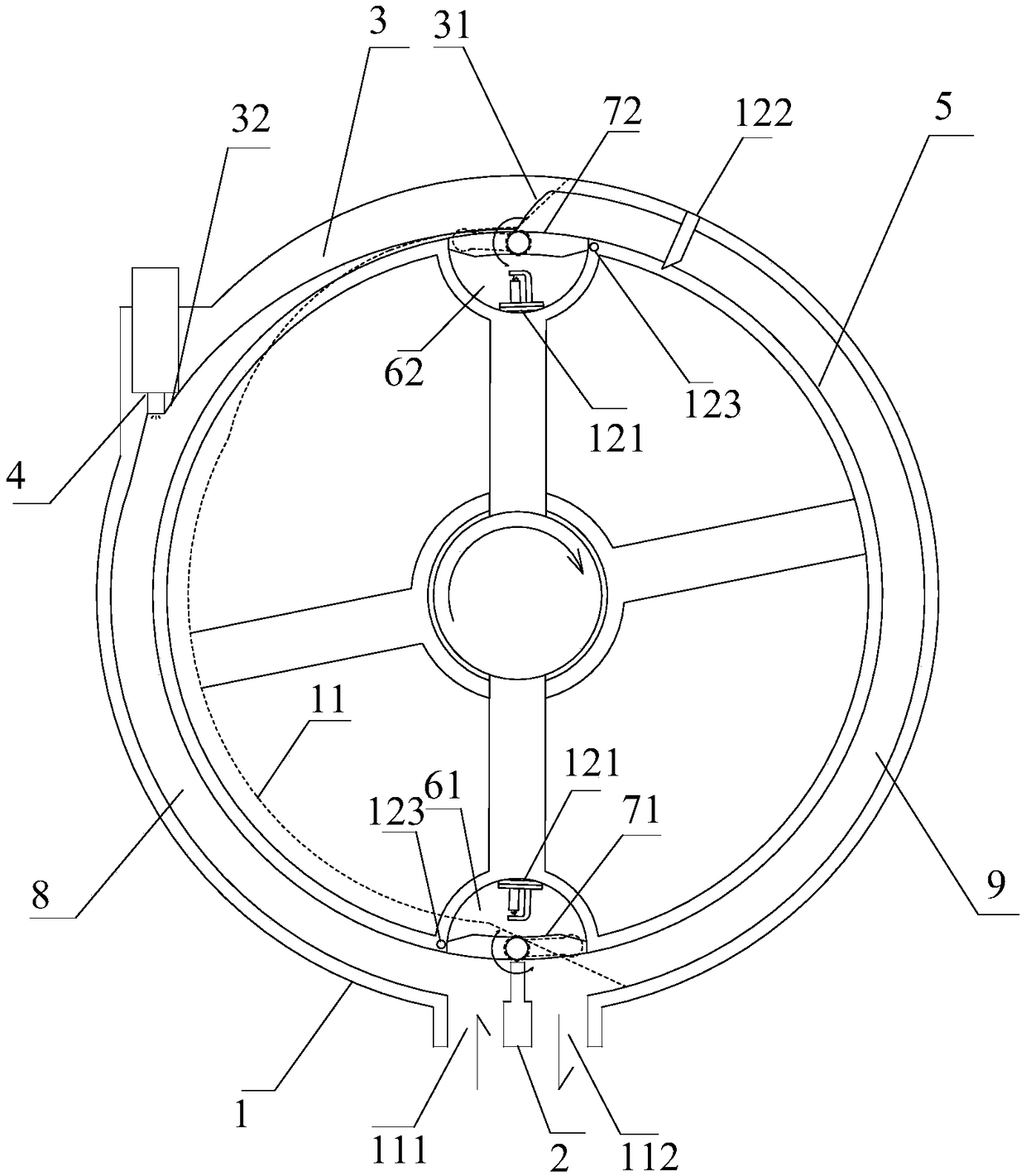

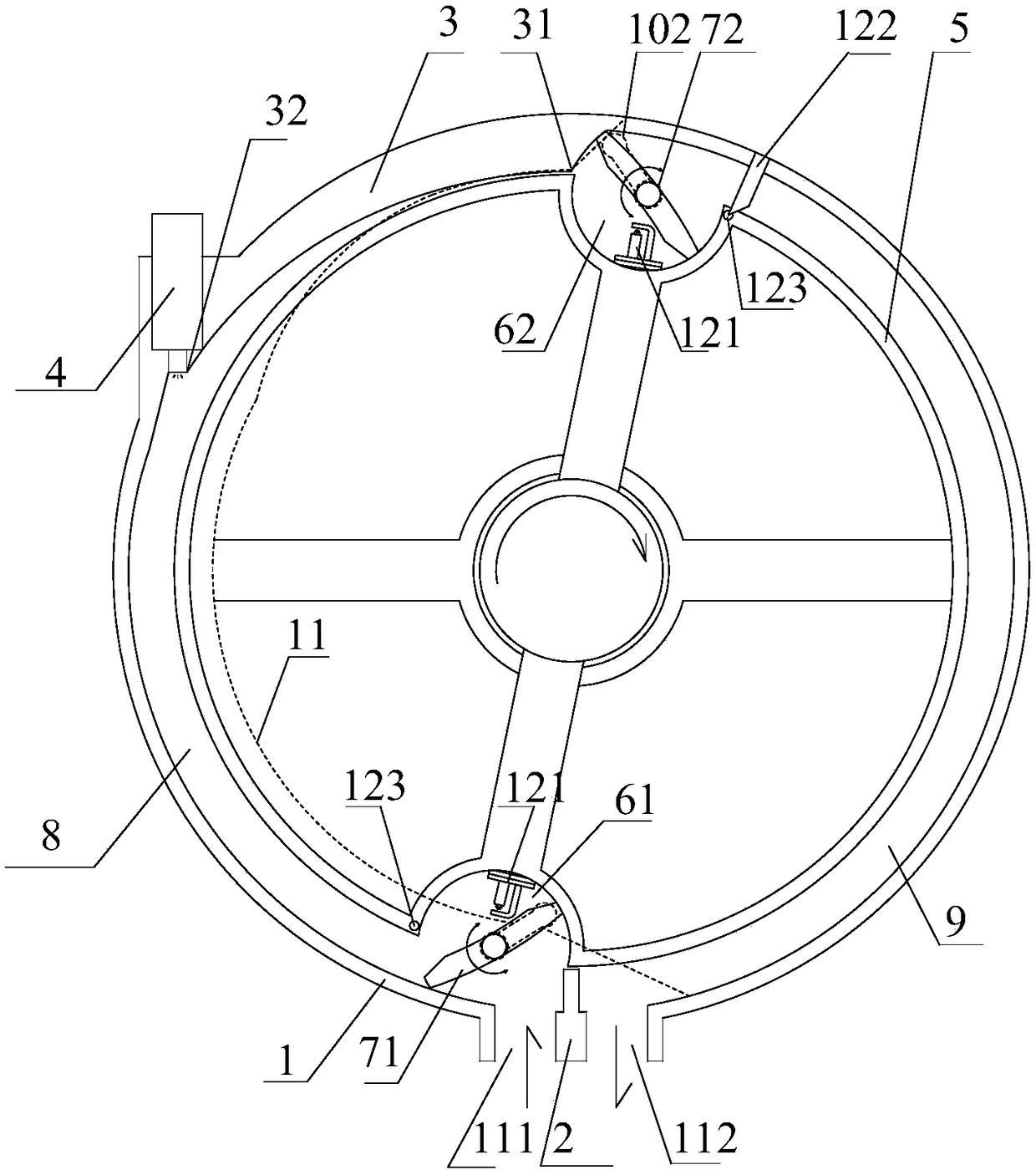

[0021] Such as figure 1 , figure 2 and image 3 As shown, a core assembly of a tangential force engine includes a casing 1 , and the casing 1 has two openings, an air inlet 111 and an air outlet 112 . The casing 1 includes a partition 2 used to separate the air inlet 111 from the exhaust outlet 112 . The partition 2 is detachably mounted on the casing 1 or integrally formed with the casing 1 .

[0022] Such as figure 1 , figure 2 and image 3 As shown, the core componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com