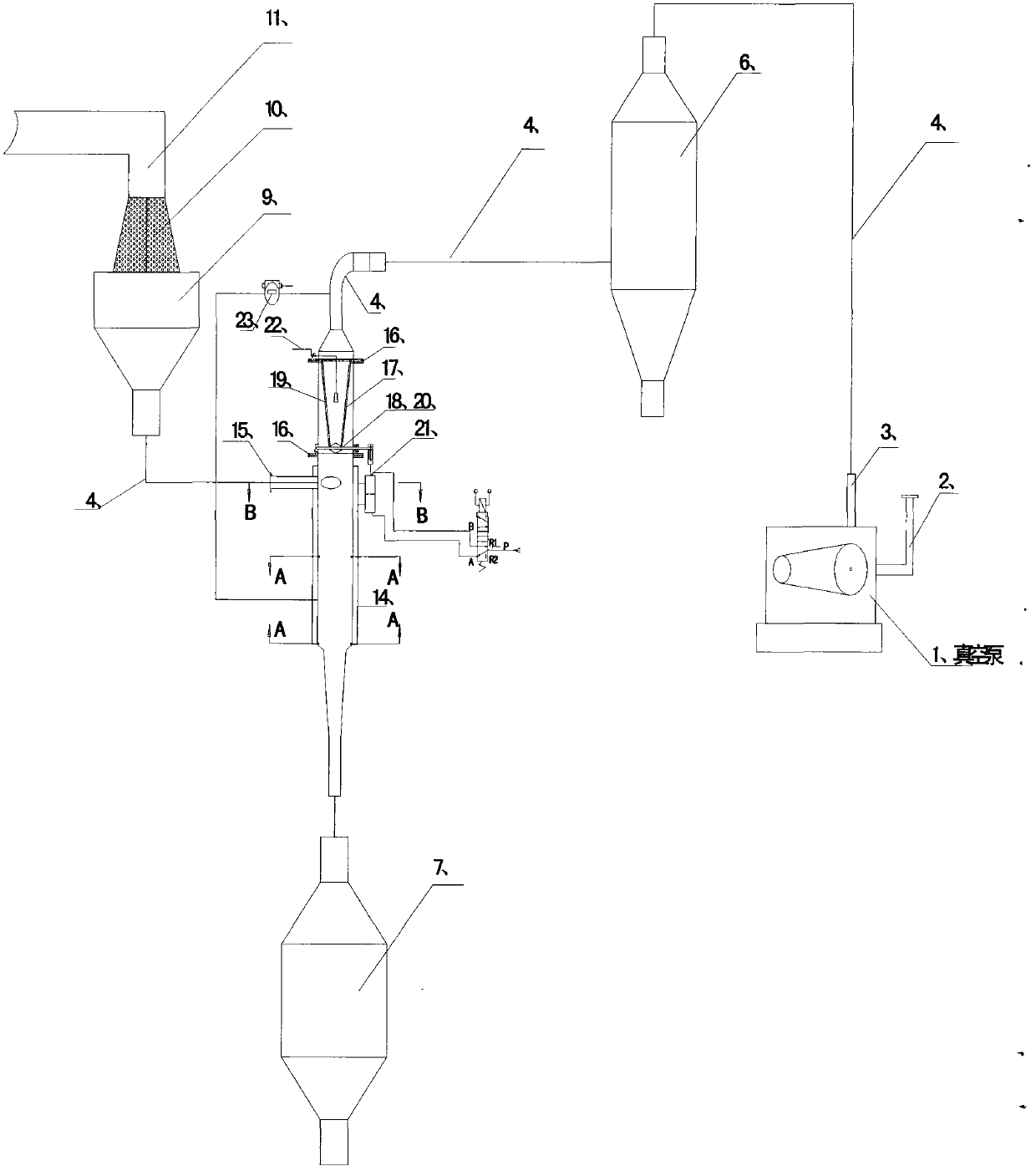

Environment-friendly negative pressure cyclone ore grain screening machine

A technology for screening machine and ore particles, which is applied in the direction of swirl device and device whose axial direction of swirl can be reversed, etc. The effect of high production efficiency and large mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

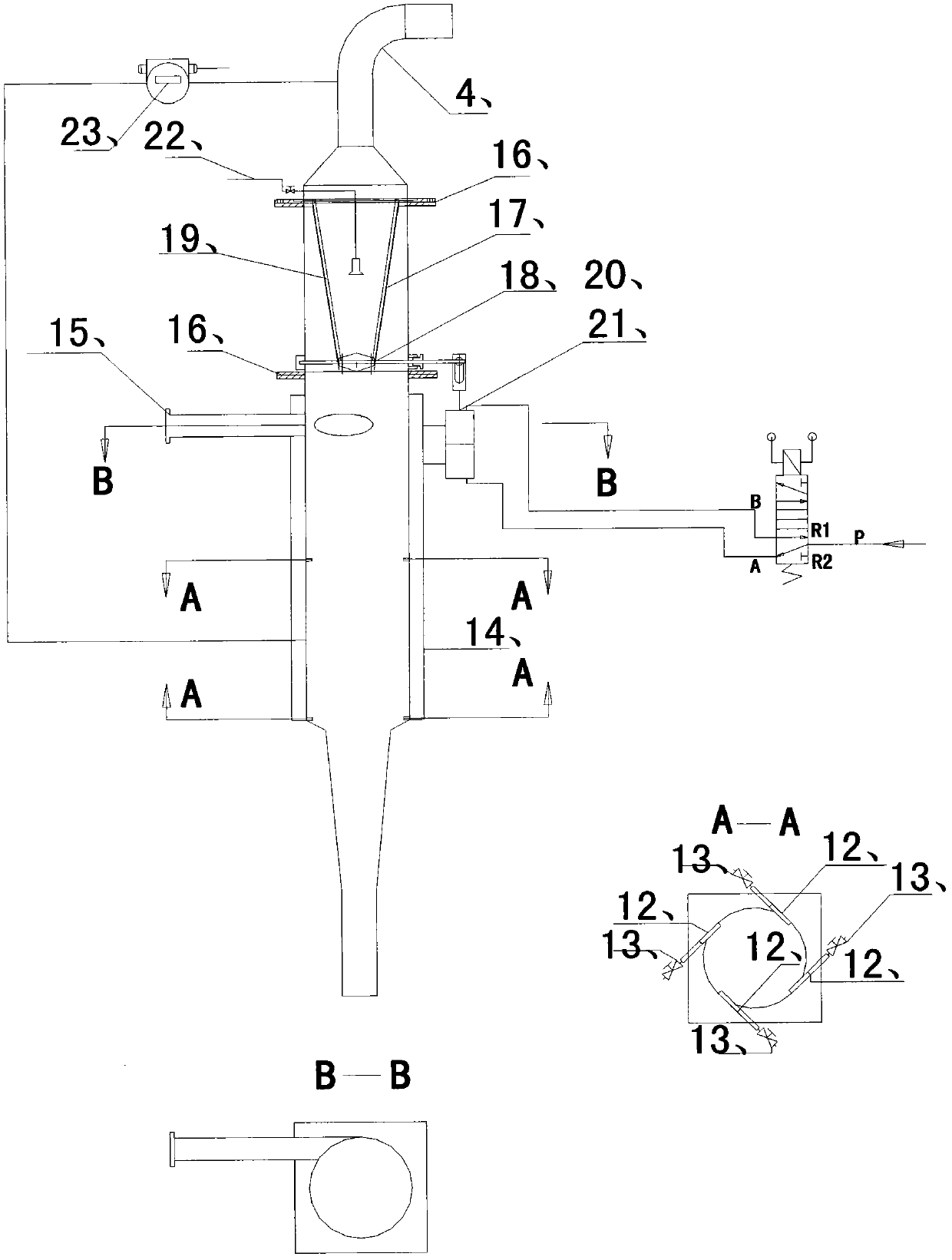

[0016] Before operation, feed the bin system--18, plate stop valve and 12, booster pipe, 13, stop valve, 18, 20, screen bottom, butterfly valve, 21, butterfly valve pneumatic control system, 22, air purging system Close, turn on 1, vacuum pump, vacuumize the negative pressure cyclone ore separator system, when the vacuum degree of the system reaches -0.08 to -0.1MPa; open: 18, plate stop valve and 12, booster tube, 13, The shut-off valve and the entire negative pressure cyclone ore screening machine system start to operate, and the volume ratio of air and mineral material is about 8%-10%.

[0017] 2. The movement path of the coarse and fine ore particles of the ore material in the negative pressure cyclone ore separator system:

[0018] a. Coarse ore particles, due to gravity, pass through the lower pipeline to 7. Coarse grain silo (note; and fine grains) to the upward moving coarse ore grains pass through 17, sieve, 18, 20, and the bottom of the sieve , Butterfly valve, 19, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com