Steel mold trolley for tunnel side wall concrete lining

A steel mold trolley and concrete technology, which is applied in tunnel lining, shaft lining, tunnel, etc., can solve the problems of large steel mold trolley, increased construction cost, poor adaptability, etc., and achieves simple design structure and convenient installation and disassembly , quality controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

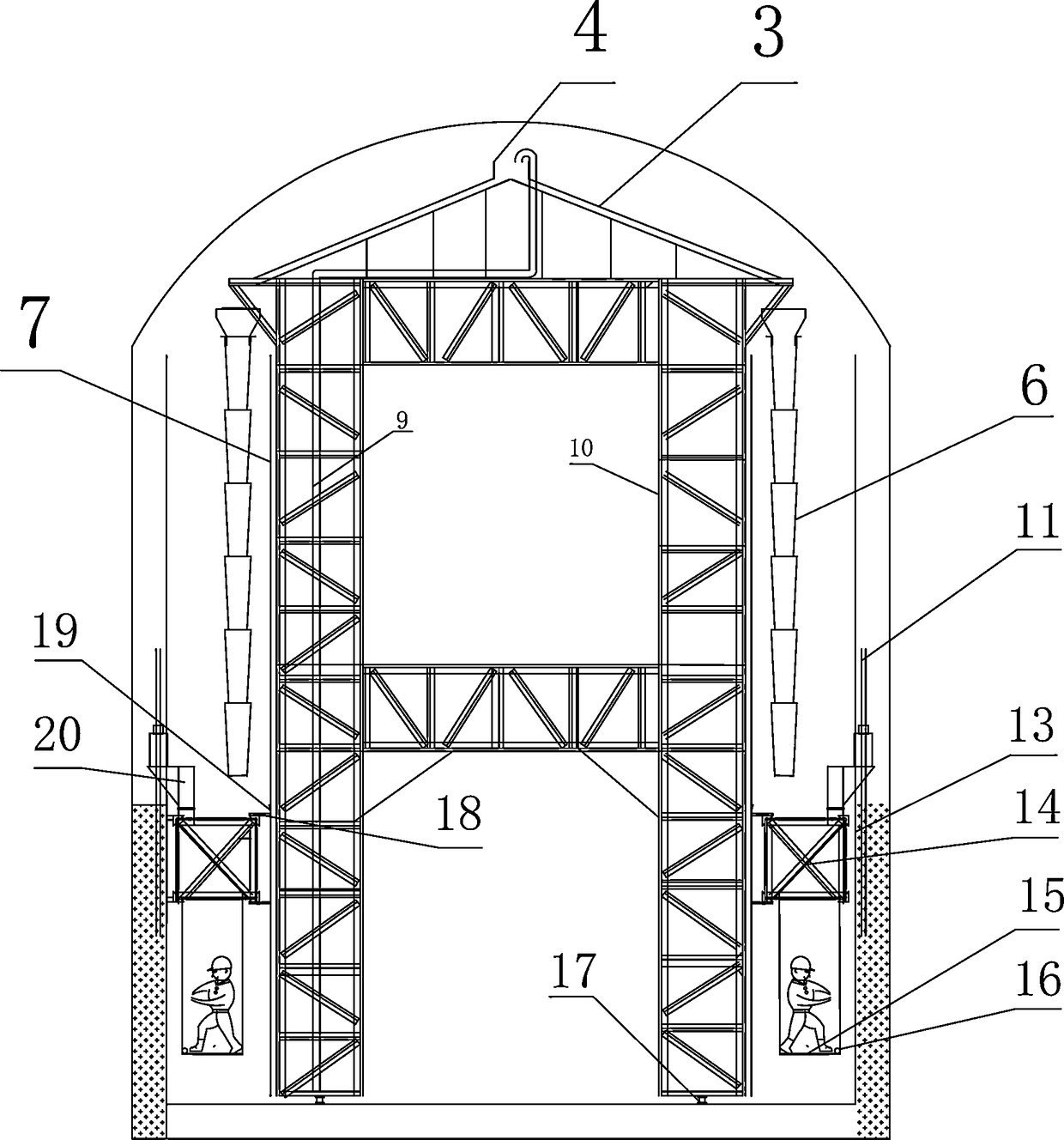

[0022] Such as Figure 1~5 Among them, a steel mold trolley for the concrete lining of the tunnel side wall, including a trolley 10, trusses 14 are arranged on both sides of the trolley 10, slide rails 7 are arranged on both sides of the trolley 10, and the truss 14 is installed on the slide The slider 19 on the rail 7 is connected, and the template 13 is fixedly connected to one end of the truss 14. A lifting mechanism is provided on the trolley 10, and the lifting mechanism drives the truss 14 to move up and down. With this structure, the lining of the tunnel side wall and the high wall of the tunnel can be realized. The difficult-to-lining areas are resolved, and the lifting system also ends up synovial well.

[0023] In the preferred solution, the lifting mechanism is a compression rod mechanism, including a support rod 11 and a jack 1, the support rod 11 is buried in the concrete, the truss 14 is provided with a lifting frame 20, the lifting frame 20 is installed on the j...

Embodiment 2

[0032] Manufacture of formwork 13: Manufacture in sections according to the design requirements in the manufacturing workshop, check and accept after pre-assembly, and number the sections after passing the test.

[0033] Reinforcement installation: It can be installed in advance, or it can be installed and slipped along with the slipform construction; it is recommended to install the reinforcement first to facilitate the rapid construction of concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com