Liquid explosive injection and detonation device for explosion fracturing of oil and gas reservoir

A technology for liquid explosives and oil and gas reservoirs, which is applied in the development of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of poor safety and reliability, large amount of liquid explosives, safety accidents, etc., and achieve the effect of reliable realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

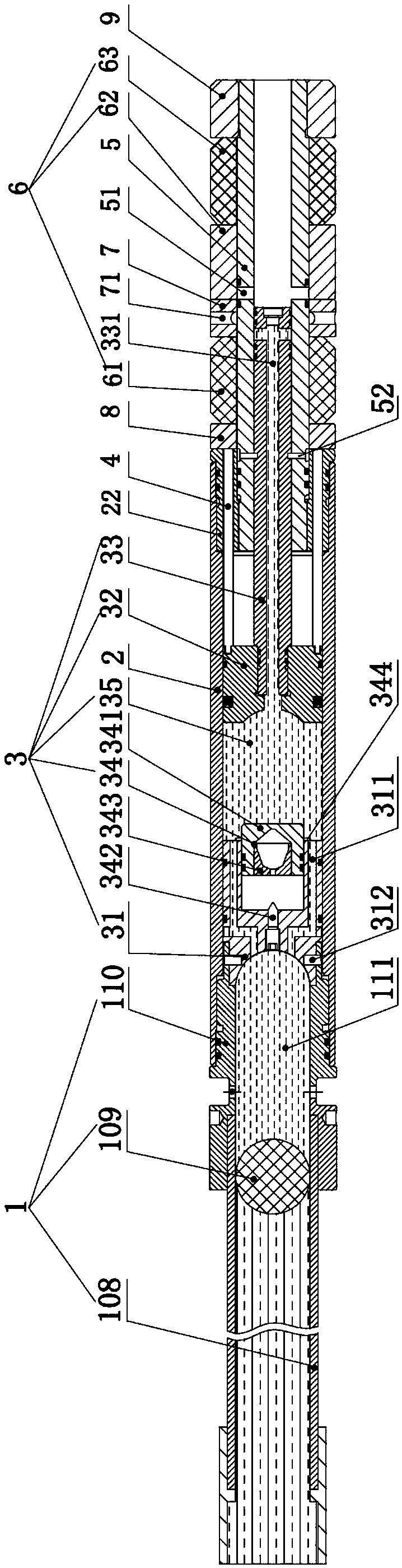

[0038]Embodiment 1 of the present invention provides a liquid explosive injection and detonation device for explosive fracturing of oil and gas reservoirs, such as figure 1 As shown, the device includes a driving unit 1, a cylinder 2, a liquid explosive injection and detonation unit 3, a driving pressure transmission unit 4, a central steel column 5, an elastic sealing unit 6 of the perforation section, and a first pressure ring 7; The driving unit 1 is located in the left end of the cylinder 2; the cylinder 2 is fixedly connected with the central steel column 5; the liquid explosive injection and detonation unit 3 is located in the cylinder 2; the perforating section elastic sealing unit 6, The first pressure rings 7 are all sleeved outside the central steel column 5; the driving pressure transmission unit 4 is located between the liquid explosive injection and detonation unit 3 and the first pressure ring 7 and runs through the gap between the cylinder barrel 2 and the centra...

Embodiment 2

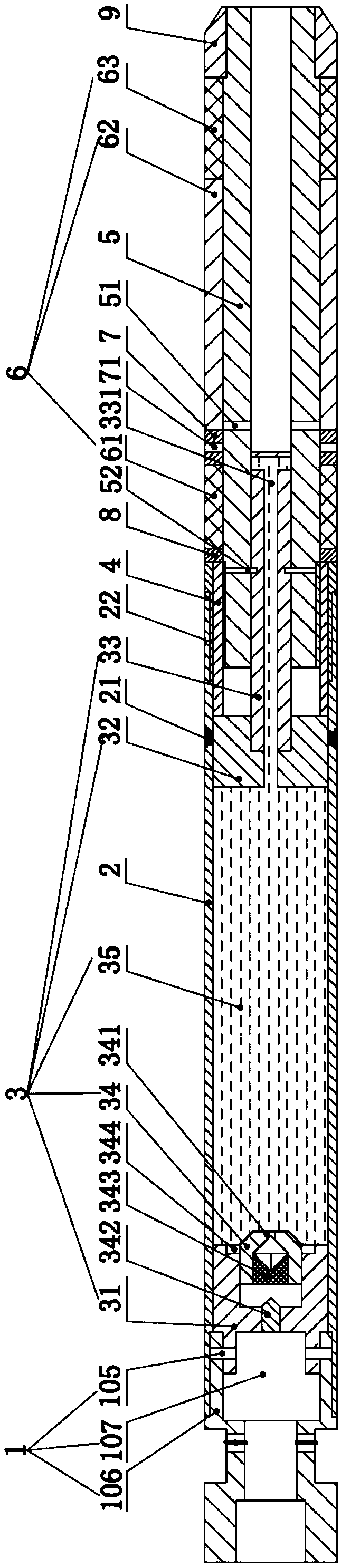

[0079] Embodiment 2 of the present invention provides a liquid explosive injection and detonation device for explosive fracturing of oil and gas reservoirs, such as Figure 2-4 As shown, the device includes a driving unit 1, a cylinder 2, a liquid explosive injection and detonation unit 3, a driving pressure transmission unit 4, a central steel column 5, an elastic sealing unit 6 of the perforation section, and a first pressure ring 7; The driving unit 1 is located in the left end of the cylinder 2; the cylinder 2 is fixedly connected with the central steel column 5; the liquid explosive injection and detonation unit 3 is located in the cylinder 2; the perforating section elastic sealing unit 6, The first pressure rings 7 are all sleeved outside the central steel column 5; the driving pressure transmission unit 4 is located between the liquid explosive injection and detonation unit 3 and the first pressure ring 7 and runs through the gap between the cylinder barrel 2 and the ce...

Embodiment 3

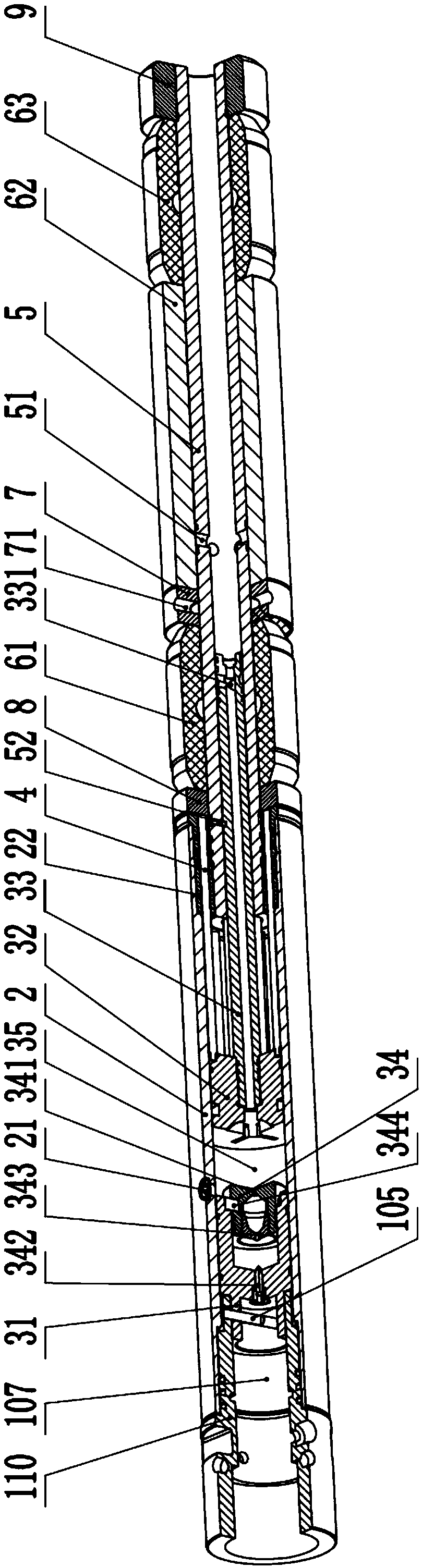

[0115] Embodiment 3 of the present invention provides a liquid explosive injection and detonation device for explosive fracturing of oil and gas reservoirs, such as Figure 5 As shown, the device includes a driving unit 1, a cylinder 2, a liquid explosive injection and detonation unit 3, a driving pressure transmission unit 4, a central steel column 5, an elastic sealing unit 6 of the perforation section, and a first pressure ring 7; The driving unit 1 is located in the left end of the cylinder 2; the cylinder 2 is fixedly connected with the central steel column 5; the liquid explosive injection and detonation unit 3 is located in the cylinder 2; the perforating section elastic sealing unit 6, The first pressure rings 7 are all sleeved outside the central steel column 5; the driving pressure transmission unit 4 is located between the liquid explosive injection and detonation unit 3 and the first pressure ring 7 and runs through the gap between the cylinder barrel 2 and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com