Two-color free-cut warp knitting fabric, production method and application thereof

A fabric and free technology, applied in the field of knitted fabrics, can solve the problems of high preparation cost, complicated process, single design and color, etc., and achieve the effect of good hooking grade, broad application prospect and not easy to curl.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

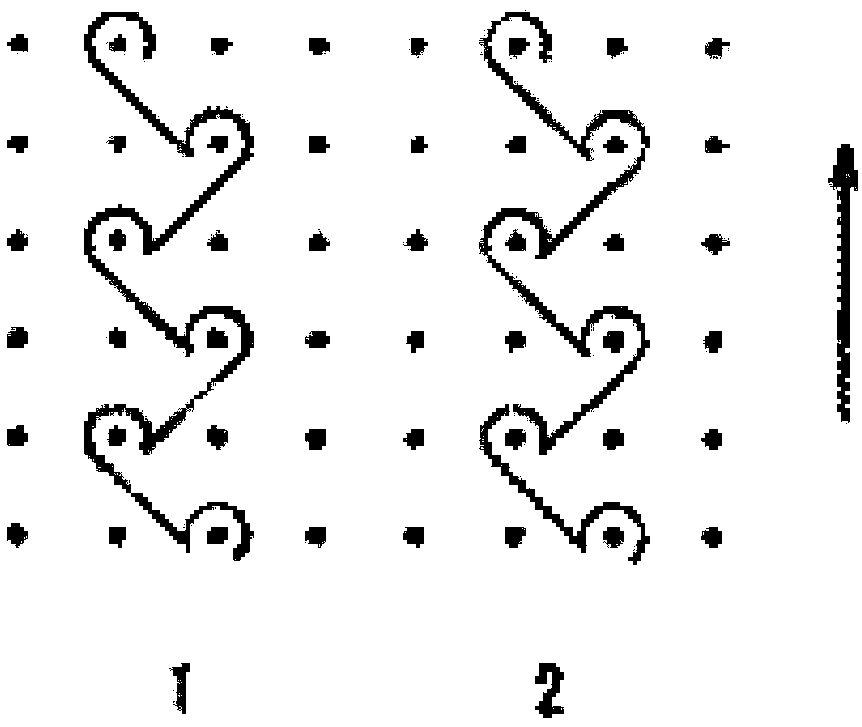

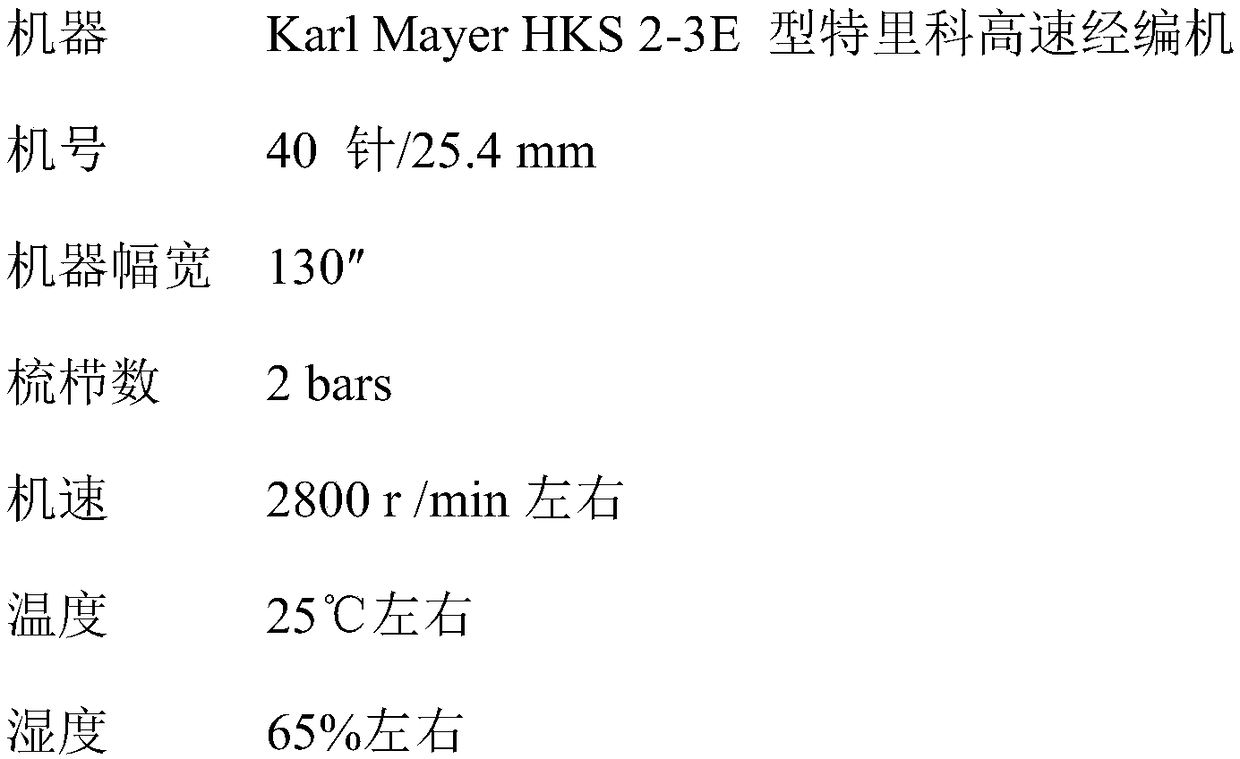

[0037] Using a single-needle bed warp knitting machine with a machine number of 40 needles / 25.4mm, a machine width of 130″, and a machine speed of 2800r / min, at an ambient temperature of 25°C and an ambient humidity of 65°, the threading method is (1A, 1B)*418 take turns through the warp, where A means bright nylon, B means round light CDP, lap yarn number: 0-1 / 2-1 / / , the knitting process is the first of two-needle open warp weaving Weave the second bar with 832 spandex yarns in the way of threading and warping, the lapping number is: 0-1 / 2-1 / / , and the weaving process is two-needle open warp weaving, and we get The two-color free-cut warp-knitted fabric, the organization chart is as follows figure 1 shown.

[0038] Specifically, the weaving process is as follows:

[0039] Device parameters:

[0040]

[0041] Raw materials: 3.3tex / 24f bright nylon, 3.3tex / 36f round CDP, 4.4tex spandex

[0042] GB1 yarn arrangement method: 1 nylon 1CDP threading through in turn

[0043]...

Embodiment 2

[0047] Compared with Example 1, except that the threading method is changed to (2A, 2B)*418 alternate threading, wherein A represents bright nylon, and B represents round light CDP, other conditions are the same as Embodiment 1, and the obtained fabric is basically the same as that of Example 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com