Stable powder ion plasma plating equipment

An ion plasma and stable technology, which is applied in coating, melt spraying, metal material coating process, etc., can solve the problems of low production efficiency of plasma powder, inconvenient movement and use, placement and dispersion, etc., and achieves a small footprint. , easy to move and use, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

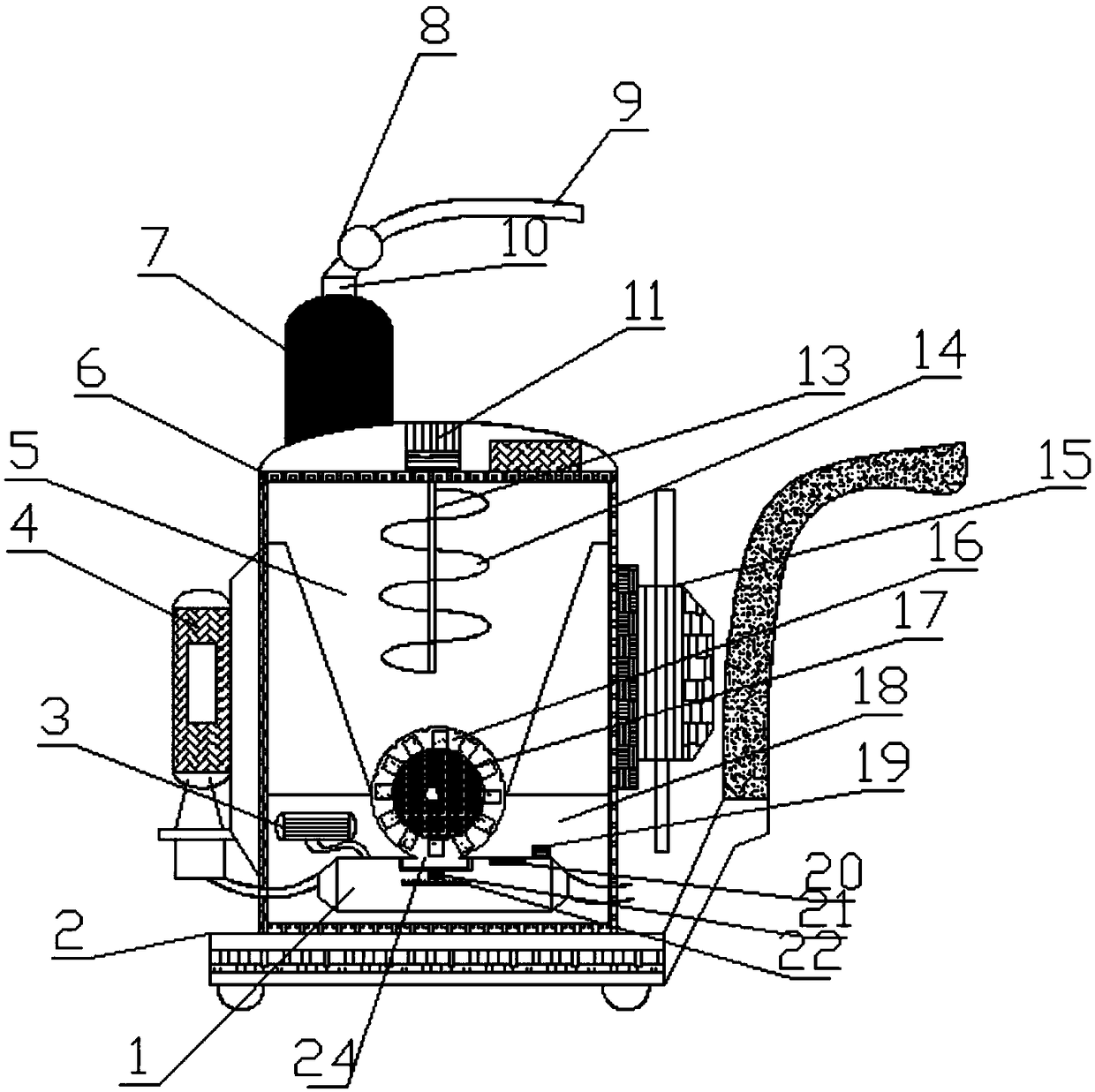

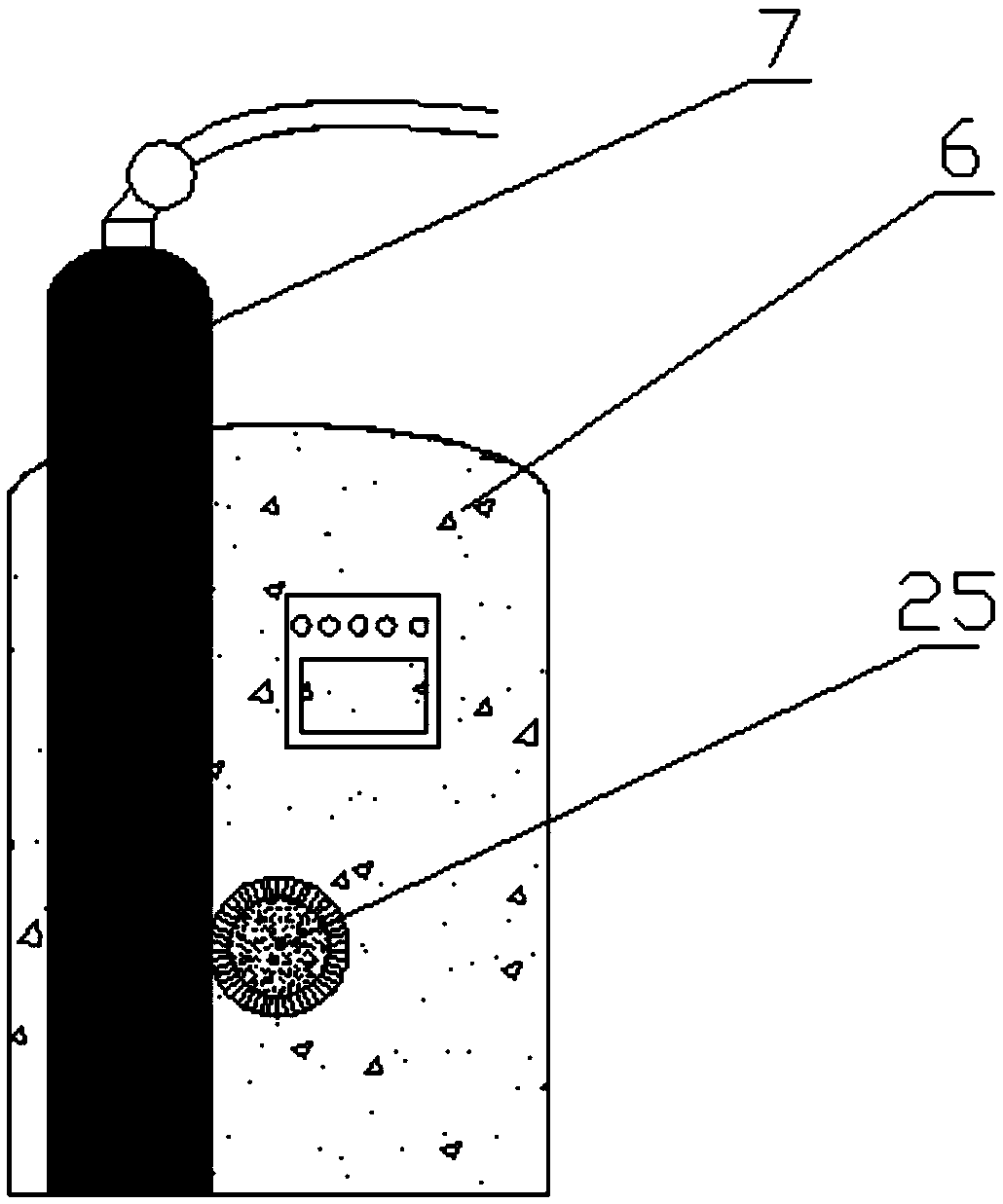

[0022] like Figure 1-2 As shown, a stable powder ion plasma coating equipment includes a base 2 and an outer shell 6, the top of the base 2 is equipped with an outer shell 6 through bolts, and one side of the outer shell 6 is provided with a hollow space through a mounting piece. Press 4, the other side of the outer casing 4 is provided with a heat exchanger 15 through a fixing member, the top of the outer casing 6 is installed with a stirring motor 11 through a mounting seat, and a stirring chamber 5 is arranged inside the outer casing 6 , the stirring chamber 5 is provided with a stirring rod 13, and the stirring rod 13 is provided with a spiral stirring blade 14 through a bolt, the bottom of the stirring chamber 5 is provided with a feeding channel 16, and the feeding channel 16 is provided with a lower Material turntable 17, the bottom of described feeding channel 16 is provided with feeding opening 24, and the lower end of described mixing chamber 5 is provided with inst...

Embodiment 2

[0036] like Figure 1-2 As shown, a stable powder ion plasma coating equipment includes a base 2 and an outer shell 6, the top of the base 2 is equipped with an outer shell 6 through bolts, and one side of the outer shell 6 is provided with a hollow space through a mounting piece. Press 4, the other side of the outer casing 4 is provided with a heat exchanger 15 through a fixing member, the top of the outer casing 6 is installed with a stirring motor 11 through a mounting seat, and a stirring chamber 5 is arranged inside the outer casing 6 , the stirring chamber 5 is provided with a stirring rod 13, and the stirring rod 13 is provided with a spiral stirring blade 14 through a bolt, the bottom of the stirring chamber 5 is provided with a feeding channel 16, and the feeding channel 16 is provided with a lower Material turntable 17, the bottom of described feeding channel 16 is provided with feeding opening 24, and the lower end of described mixing chamber 5 is provided with inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com