Biomass organic fertilizer preparation device

A technology of organic fertilizer and preparation device, which is applied in the preparation of organic fertilizer, organic fertilizer equipment, organic fertilizer and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

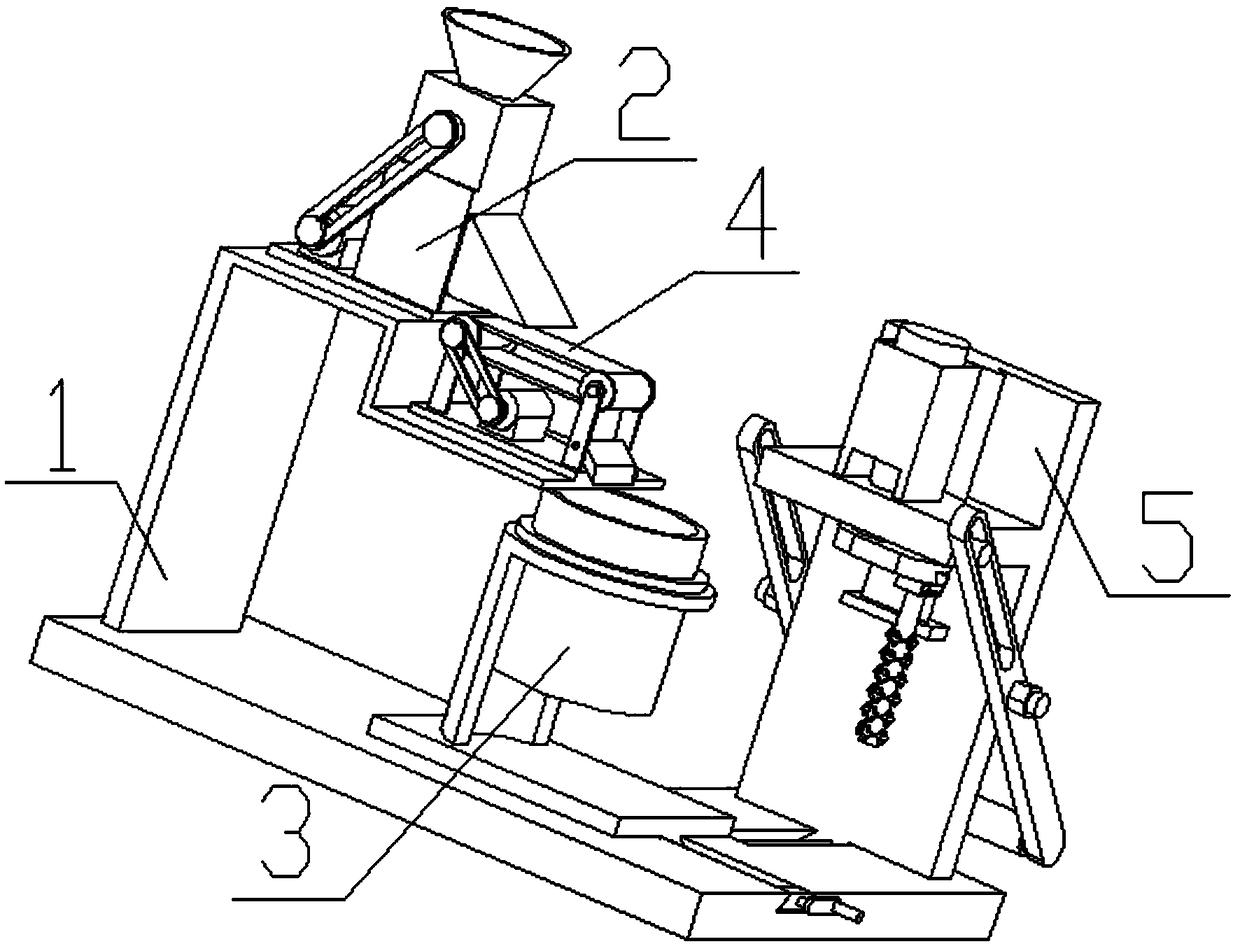

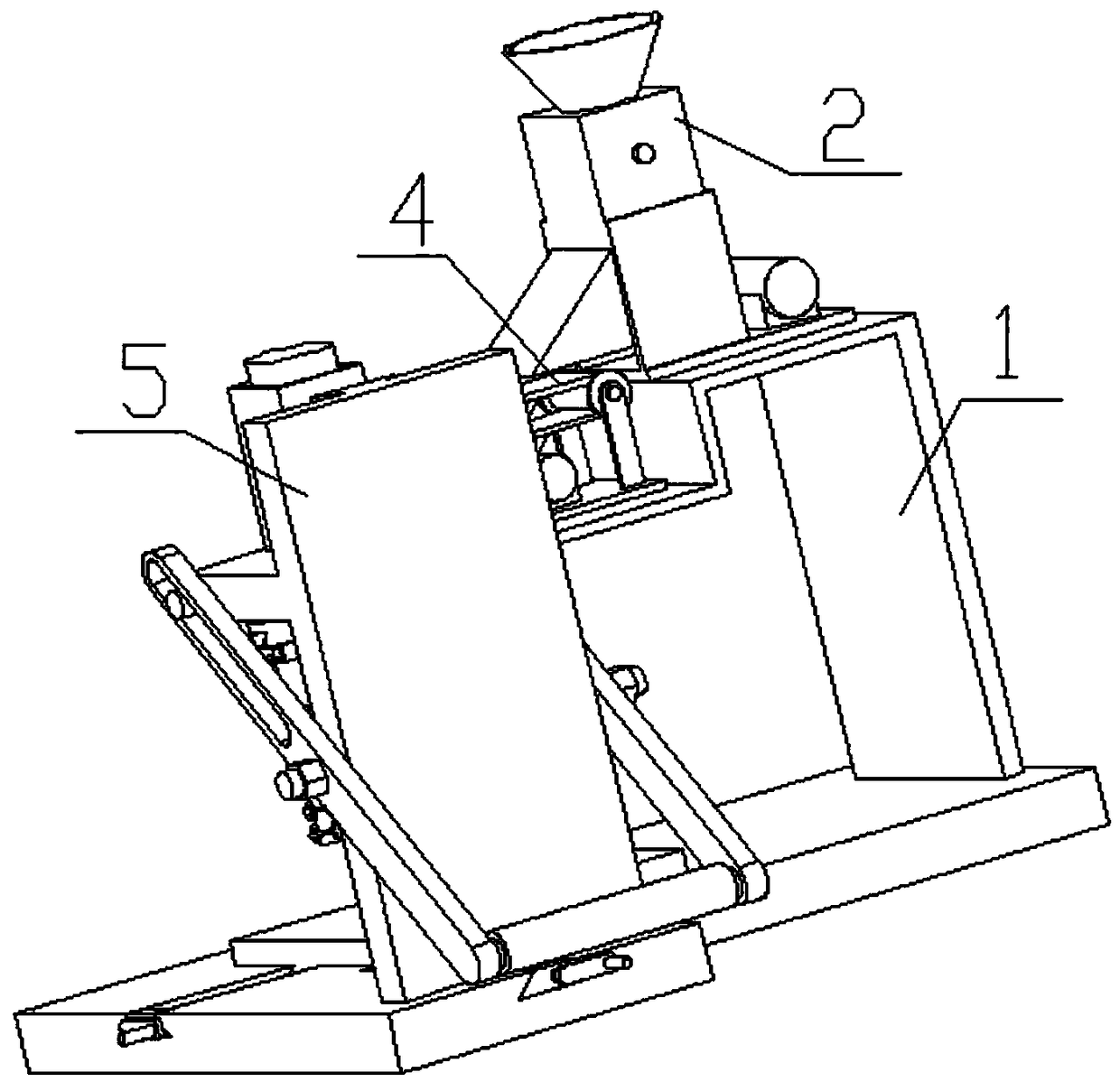

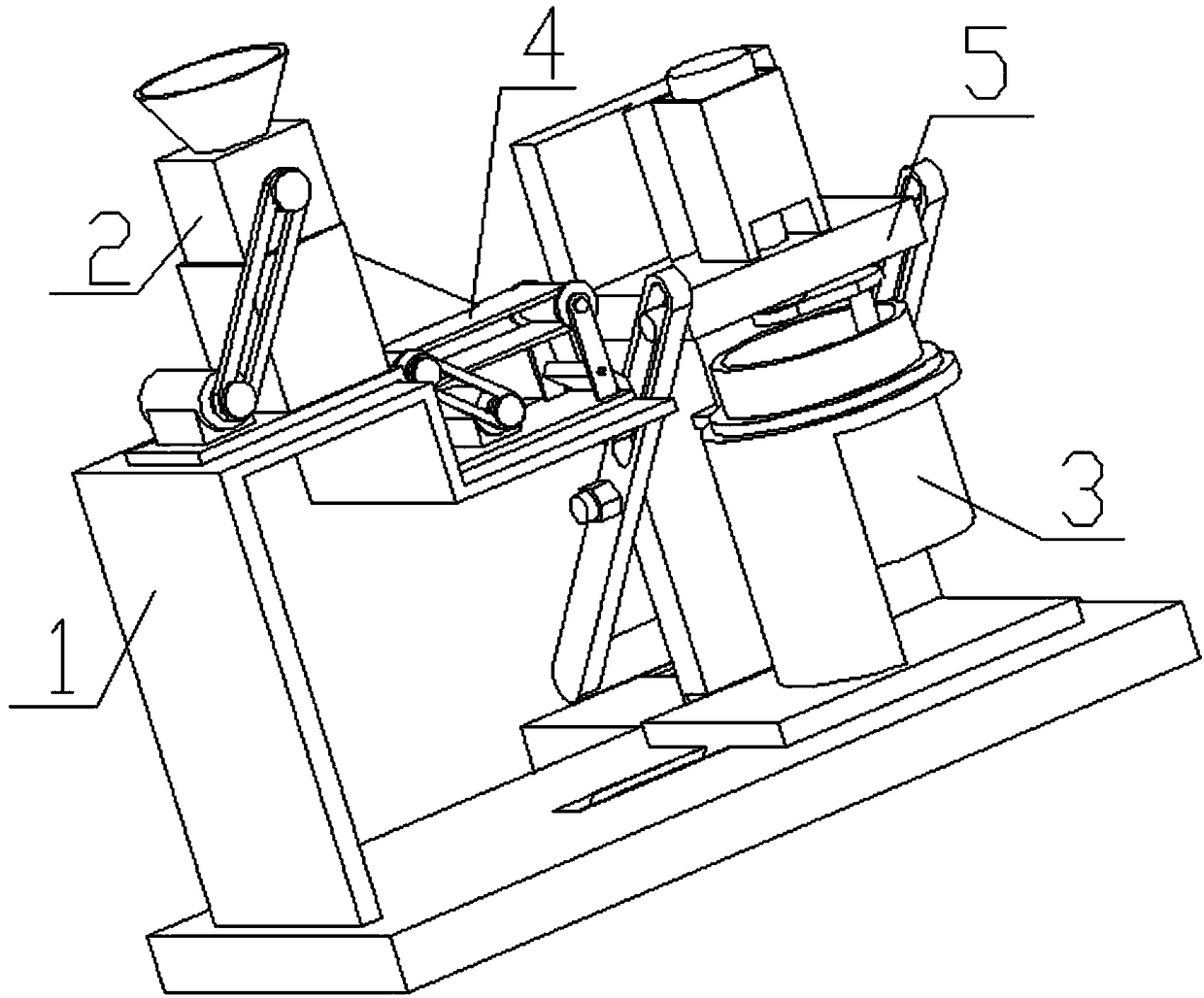

[0040] Combine below Figure 1-23 Describe this embodiment, a biomass organic fertilizer preparation device, including a support frame 1, a crushing mechanism 2, a holding device 3, a transmission mechanism 4 and a stirring device 5, and pour organic matter such as straw or feces into the feeding port 2-2, Power on the motor I2-12, the motor I2-12 drives the pulley II2-13 to rotate, the pulley II2-13 drives the pulley I2-5 to rotate, the pulley I2-5 drives the connecting shaft 2-15 to rotate, and the connecting shaft 2-15 drives the rotating column 2 -3 rotation, multiple crushing blocks 2-4 rotate with the rotating column 2-3, multiple crushing blocks 2-4 can crush organic matter such as straw or feces, and the crushed organic matter passes through the leakage material sieve 2-7, after passing through Sliding surface 2-8, organic matter just slides out crushing mechanism 2 and falls directly on the conveyor belt 4-10, and motor II4-3 is energized, and motor II4-3 can drive be...

specific Embodiment approach 2

[0045] Combine below Figure 1-23 Describe this embodiment, this embodiment will further explain the first embodiment, the transmission mechanism 4 includes a load fixing plate 4-1, a motor fixing block II4-2, a motor II4-3, a pulley III4-4, and a bearing with a bearing Seat II4-5, rotating shaft 4-6, driving wheel 4-7, belt pulley IV4-8, belt II4-9, conveyor belt 4-10 and gentle slope slope 4-11, fixedly connected with motor on the bearing fixed plate 4-1 Block II4-2, the motor fixing block II4-2 can provide a fixed space for the motor II4-3, the motor II4-3 is fixedly connected on the motor fixing block II4-2, the motor II4-3 can drive the pulley III4-4 to rotate, the pulley III4-4 is fixedly connected to the front end of the output shaft of the motor II4-3, and the four corners of the upper surface of the load-bearing fixed plate 4-1 are fixedly connected with bearing seats II4-5 with bearings, and the bearing seats II4-5 with bearings are all fixedly connected with each ot...

specific Embodiment approach 3

[0046] Combine below Figure 1-23 This embodiment will be described. This embodiment will further describe the second embodiment. The lower surface of the bearing and fixing plate 4-1 is fixedly connected to the upper surface of the bearing plate 1-2-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com