Tin niobate nanosheet, preparation method thereof and application of tin niobate in preparation of lithium battery

A nanosheet, lithium ion battery technology, applied in nanotechnology, nanotechnology, secondary batteries and other directions, can solve problems such as short circuit and safety hazards of lithium dendrite batteries, and achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

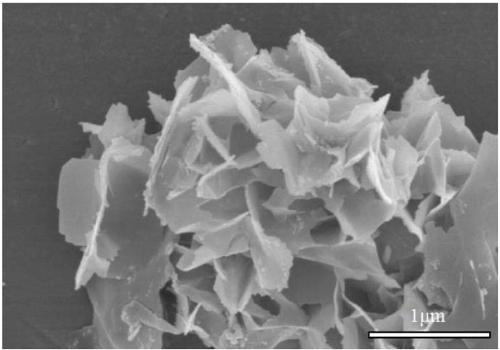

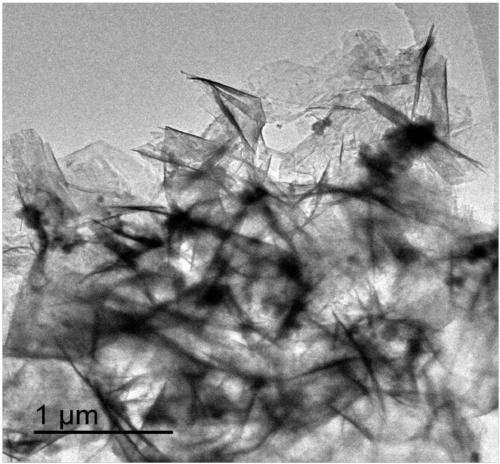

[0026] SnNb 2 o 6 Preparation method of nanosheets:

[0027] 1) Weigh / measure 0.7g of K 8 Nb 6 o 19 , 0.4g of SnCl 2 2H 2 O and 30mL mass fraction are 30% ethanol aqueous solution, are placed in the reactor that liner is polytetrafluoroethylene, adopt magnetic stirring to fully stir and mix uniformly, make mixed solution;

[0028] 2) Put the reaction kettle into an oven, and the mixed solution was hydrothermally reacted at 120°C for 2 hours, and the substance generated by the hydrothermal reaction was naturally cooled to room temperature, and the cooled substance was centrifuged, and washed several times with deionized water and absolute ethanol Then put it into a vacuum drying oven and dry at 30°C for 1 hour to obtain SnNb 2 o 6 Nanosheets.

[0029] Using the obtained SnNb 2 o 6 The method for making the negative electrode of lithium-ion battery with nanosheets:

[0030] The resulting SnNb 2 o 6 The nanosheets, sodium carboxymethyl cellulose and acetylene black ...

Embodiment 2

[0032] SnNb 2 o 6 Preparation method of nanosheets:

[0033] 1) Weigh / measure 0.7g of K 8 Nb 6 o 19 , 0.6g of SnCl 2 2H 2 0 and 40mL mass fraction are 40% ethanol aqueous solution, be placed in the reactor that liner is polytetrafluoroethylene, adopt magnetic stirring to fully stir and mix uniformly, make mixed solution;

[0034] 2) Put the reaction kettle into an oven, and the mixed solution is hydrothermally reacted at 160°C for 8 hours, the substance generated by the hydrothermal reaction is naturally cooled to room temperature, the cooled substance is centrifuged, and washed several times with deionized water and absolute ethanol Then put it into a vacuum drying oven and dry at 50°C for 1 hour to obtain SnNb 2 o 6 Nanosheets.

[0035] Using the obtained SnNb 2 o 6 The method for making the negative electrode of lithium-ion battery with nanosheets:

[0036] The resulting SnNb 2 o 6 The nanosheets, sodium carboxymethyl cellulose and acetylene black are mixed an...

Embodiment 3

[0038] SnNb 2 o 6 Preparation method of nanosheets:

[0039] 1) Weigh / measure 0.7g of K 8 Nb 6 o 19 , 1g of SnCl 2 2H 2 O and 50mL mass fraction are 50% ethanol aqueous solution, are placed in the reactor that liner is polytetrafluoroethylene, adopt magnetic stirring to fully stir and mix uniformly, make mixed solution;

[0040] 2) Put the reaction kettle into an oven, and the mixed solution was hydrothermally reacted at 200°C for 12 hours, the substance generated by the hydrothermal reaction was naturally cooled to room temperature, the cooled substance was centrifuged, and washed several times with deionized water and absolute ethanol Then put it into a vacuum drying oven and dry it at 60°C for 1 hour to obtain SnNb 2 o 6 Nanosheets.

[0041] Using the obtained SnNb 2 o 6The method for making the negative electrode of lithium-ion battery with nanosheets:

[0042] The resulting SnNb 2 o 6 Nanosheets, sodium carboxymethyl cellulose and acetylene black are mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com