A kind of automobile multifunctional driving axle

A multi-functional, drive axle technology, applied in the direction of brakes, vehicle parts, brake components, etc., can solve the problems of unable to perform normal deceleration and braking, unable to brake, and unable to perform normal braking of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

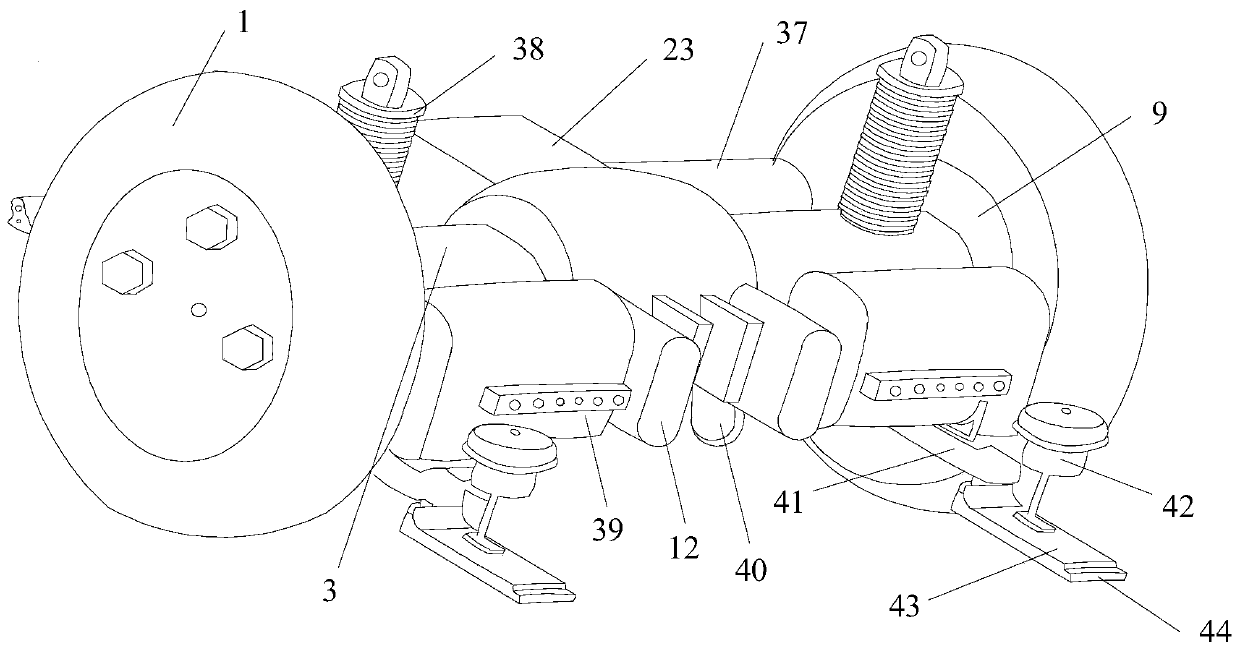

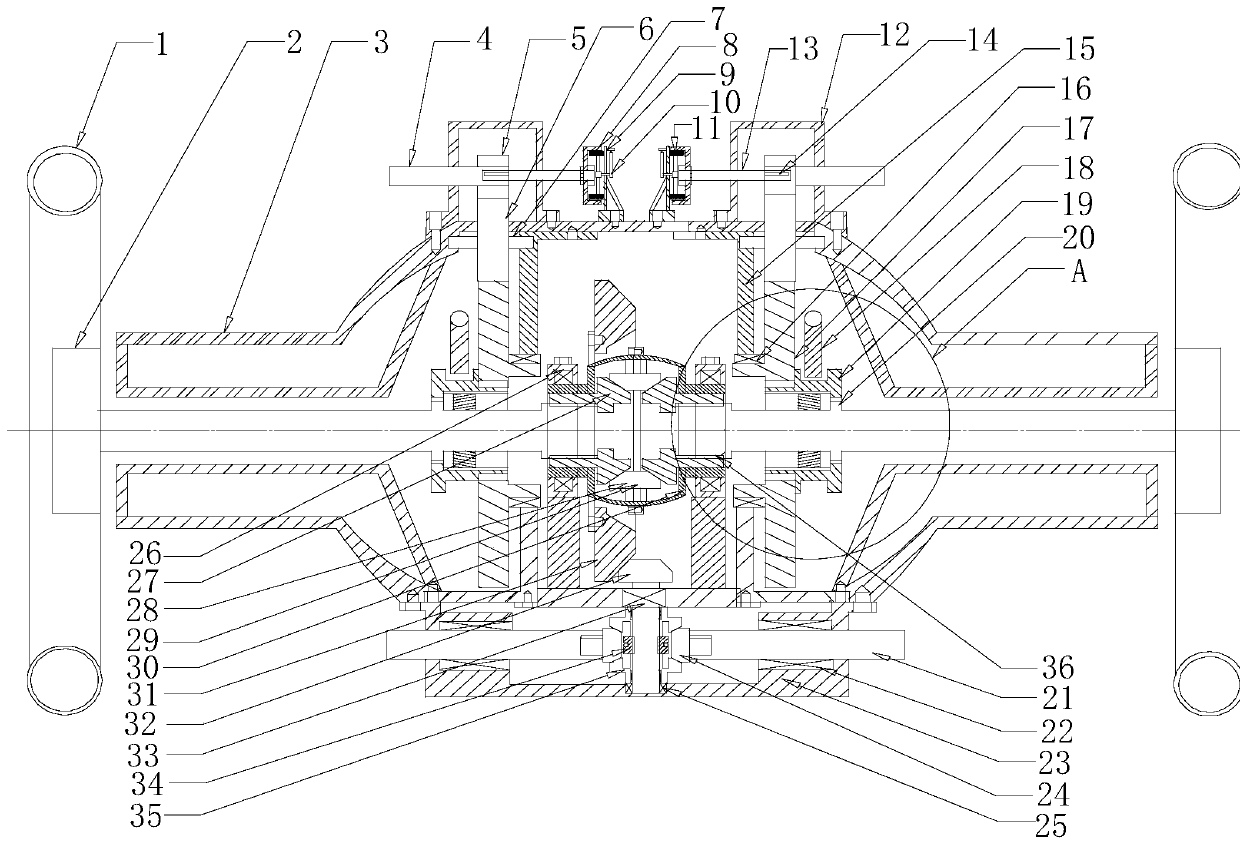

[0028] Such as Figure 1~5 As shown, the present embodiment includes a hollow bridge 3, a differential device arranged inside the hollow bridge 3, and drive shafts 2 respectively arranged at both ends of the differential device. Basin teeth 31 are arranged on the outer wall of the differential device. The outer peripheral wall of each drive shaft 2 is provided with annular secondary teeth 20, and two toothed disc covers 15 are arranged inside the hollow bridge 3, and a bearing I16 is provided on each toothed disc cover 15. , the main tooth 17 is rotatably set in the bearing I16, and two intermediate gear shafts 7 are rotatably arranged inside the hollow bridge 3, and each intermediate gear shaft 7 is fixed with an intermediate tooth 6 that matches the main tooth 17. The outer wall of the hollow bridge 3 is provided with a case cover 12, and the part of the middle tooth 6 runs through the outer wall of the hollow bridge 3 and then extends towards the case cover 12. A mechanical...

Embodiment 2

[0034] Such as Figure 1~3 As shown, on the basis of Embodiment 1, the present embodiment is provided with a driving box cover 23 on the outer wall of the hollow bridge 3, and a central shaft, bearing IV 25 and bearing III 33 are arranged in the driving box cover 23, and the central shaft One end of the shaft is rotated in the bearing IV 25, and the other end of the central shaft passes through the outer wall of the bearing III 33 and the drive box cover 23 and then enters the hollow bridge 3, and the end of the central shaft entering the hollow bridge 3 is fixed with a basin tooth. 31 is matched with the angular gear 32, and a drive gear sleeve 34 is provided in the middle of the central shaft, and the drive planetary gear I 35 is fixed on the drive gear sleeve 34, and drive motors 37 are respectively provided on both sides of the drive case cover 23, and two drive gears The motor drive shaft 21 of the motor 37 respectively penetrates the two side walls of the drive case cove...

Embodiment 3

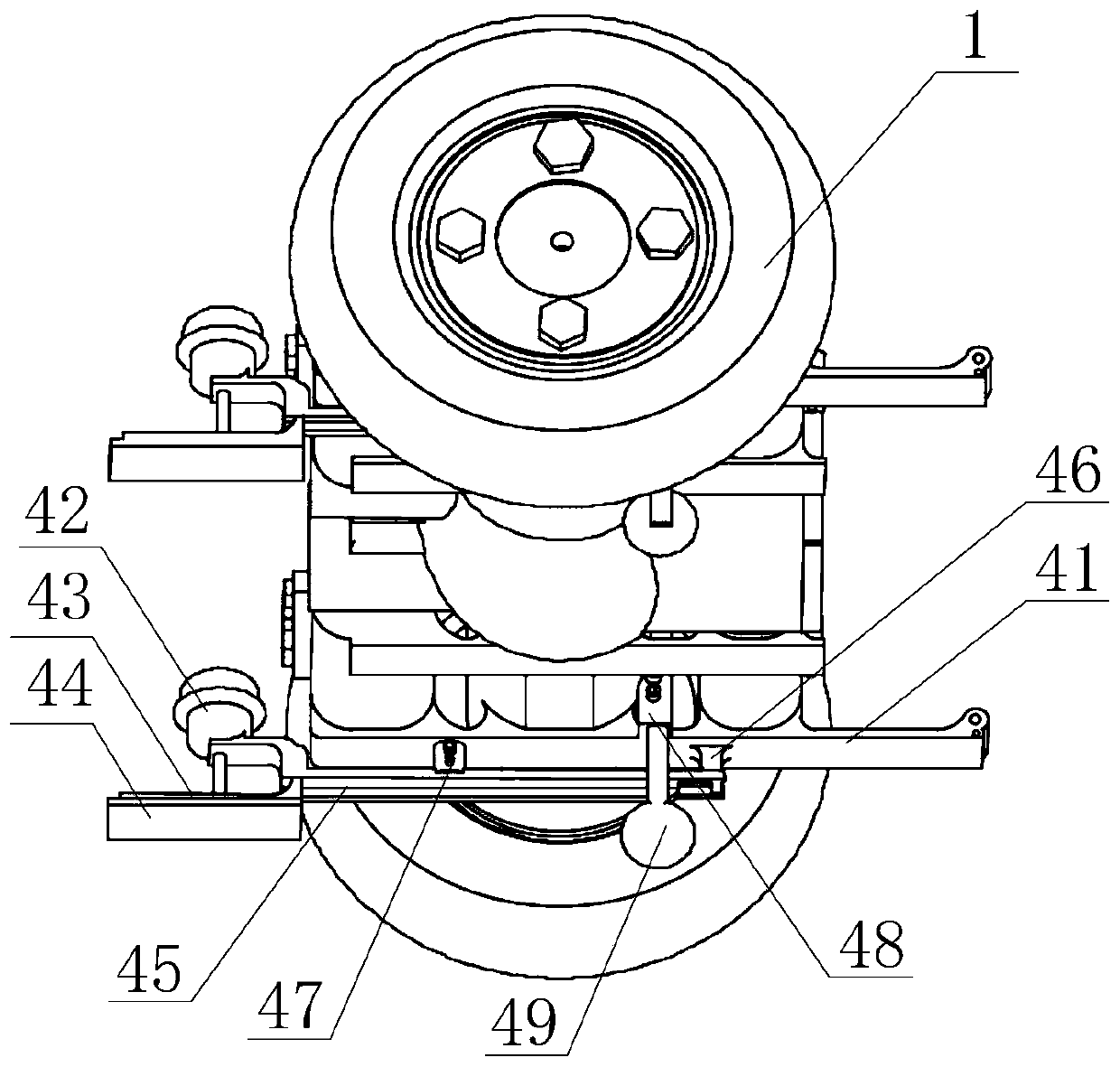

[0036] Such as Figure 1~2 As shown, on the basis of Embodiment 1, the present embodiment is provided with a pull arm 41 on the lower surface of the hollow bridge 3 , and an adjusting hydraulic cylinder and a straight arm seat 46 are fixed on the bottom of the pull arm 41 . One end is hinged with the straight arm seat 46, and the output end of the adjustment hydraulic cylinder 47 is hinged with the middle part of the straight arm 45. On the other end of the straight arm 45, a brake air pump 42 is installed, and on the output end of the brake air pump 42 An emergency brake plate 43 is connected, and an emergency brake pad 44 is fixed on the lower surface of the emergency brake plate 43 . When the car performs emergency braking, the driver will be injured to a greater extent due to inertial factors, especially when the distance between the car and the car is large and the speed is fast, the main brake system cannot make effective braking, that is, the driving The probability of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com