Ceramic automatic glazing machine

A technology for automatic glazing and ceramics, which is applied in the field of ceramic processing and can solve problems such as inability to clamp ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

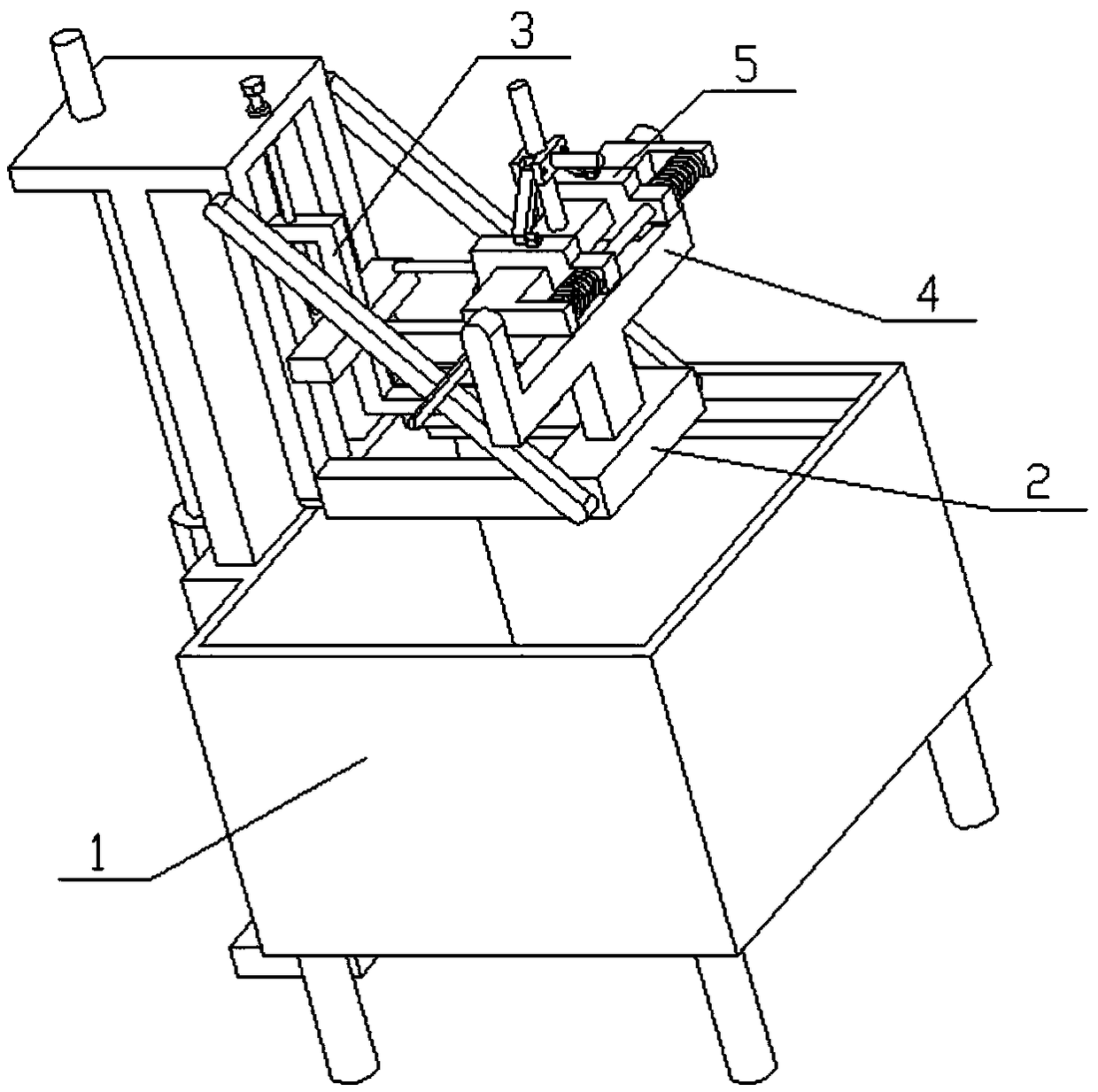

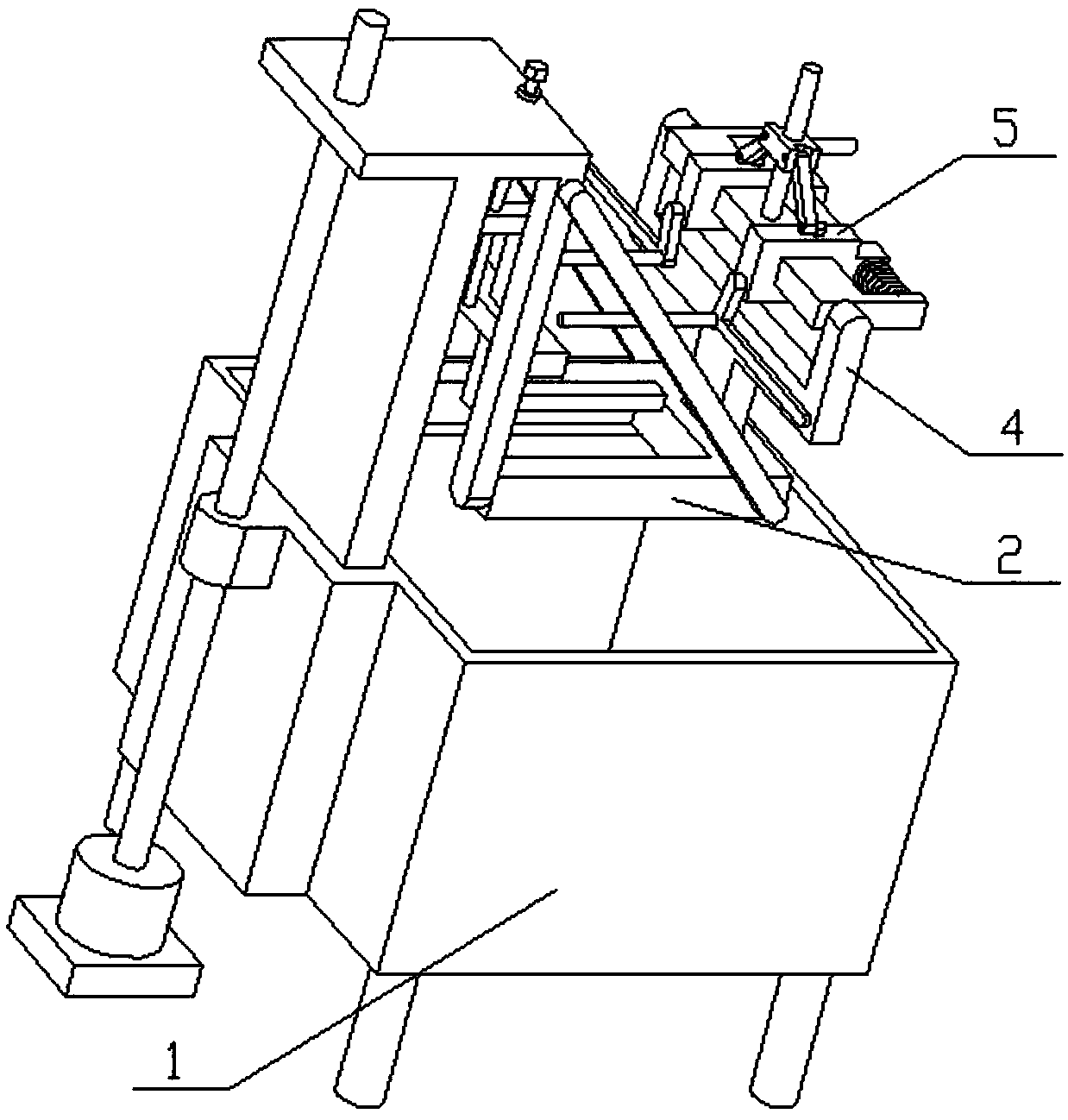

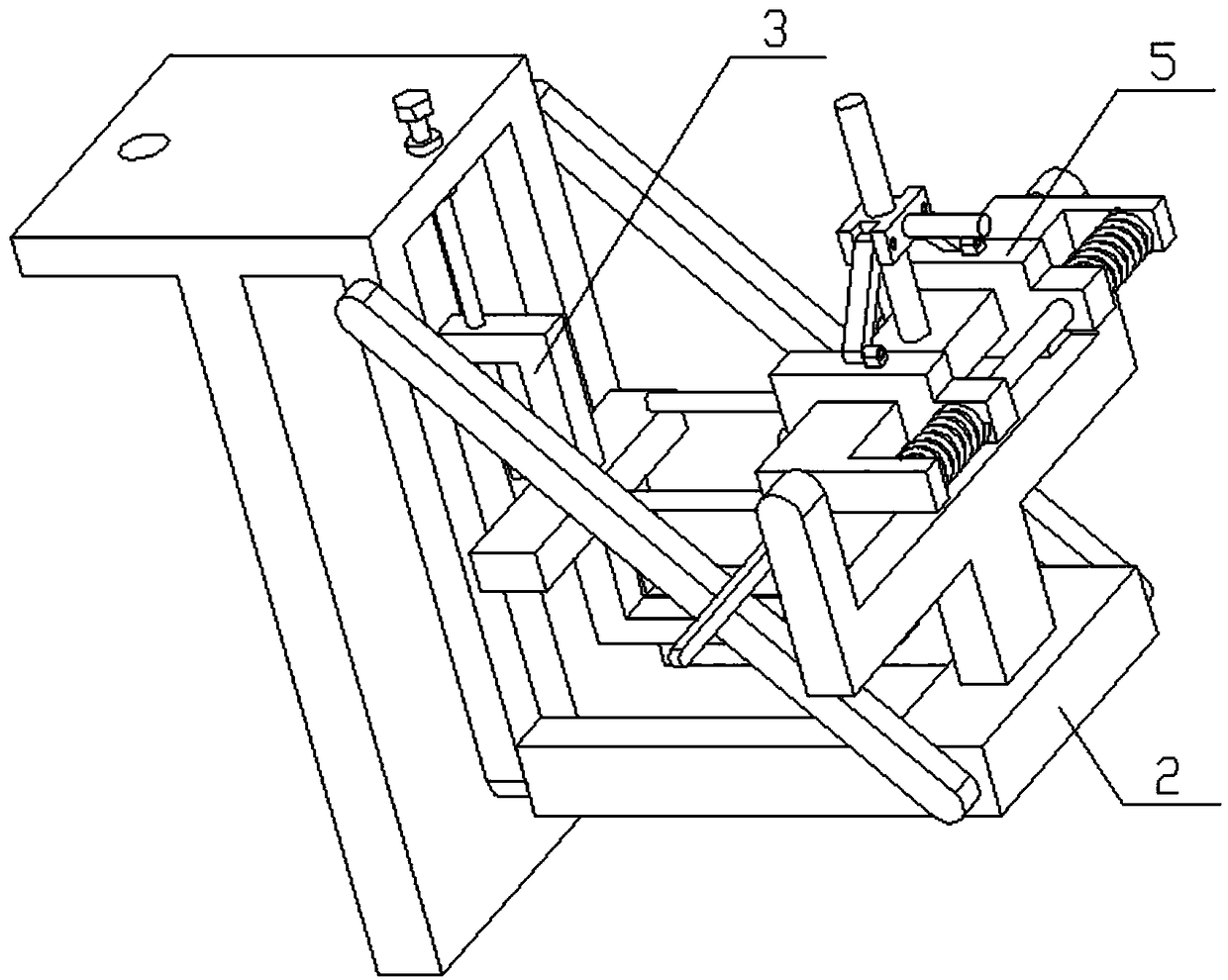

[0028] Combine below Figure 1-11 Describe this embodiment, the present invention relates to the field of ceramic processing, more specifically a kind of ceramic automatic glazing machine, including bottom box assembly 1, lifting frame 2, ceramic bracket 3, fixed carriage 4 and clamping frame 5, When the present invention is used, the bottom of the ceramic needs to be placed on the upper end of the bottom support bar 3-1, and the upper end of the ceramic can be clamped by two clamping rods 5-6, and the present invention can clamp ceramics of different sizes, and the ceramic clamping After the completion, the motor can drive the ceramics to move down and enter the glaze liquid for glazing. After the glazing is completed, the ceramics can be lifted to air dry.

[0029] The lifting frame 2 is slidably connected to the left end of the bottom box assembly 1, the lower end of the ceramic bracket 3 is slidably connected to the lifting frame 2, the upper end of the ceramic bracket 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com