Connection rod crawling pipeline robot

The technology of a pipeline robot and a robot body is applied in the field of connecting rod creeping pipeline robots, which can solve the problems of poor folding effect of the connecting rod, inconvenient disassembly, large volume, etc., and achieve the effect of being easy to fold and place and easy to retract.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

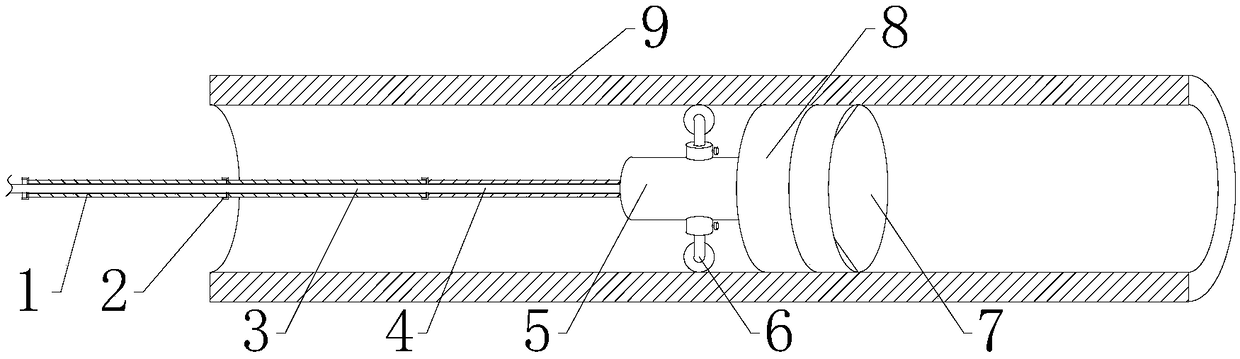

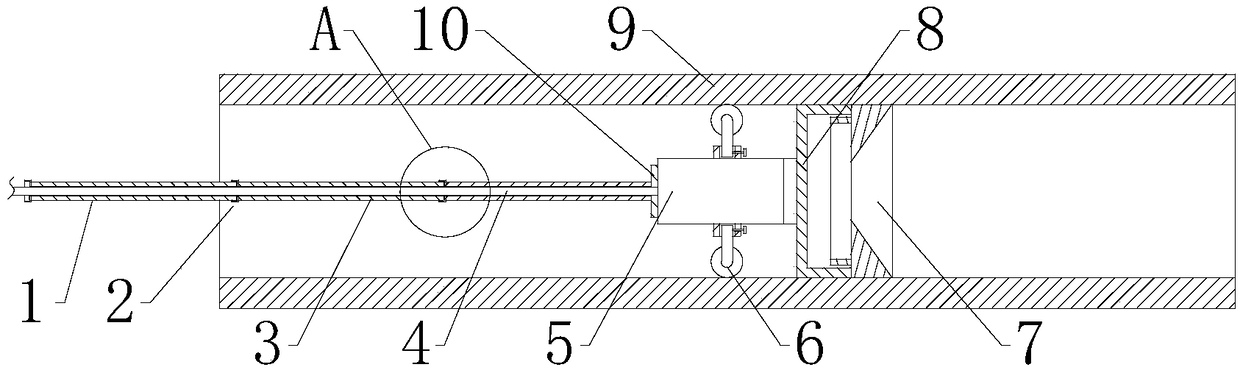

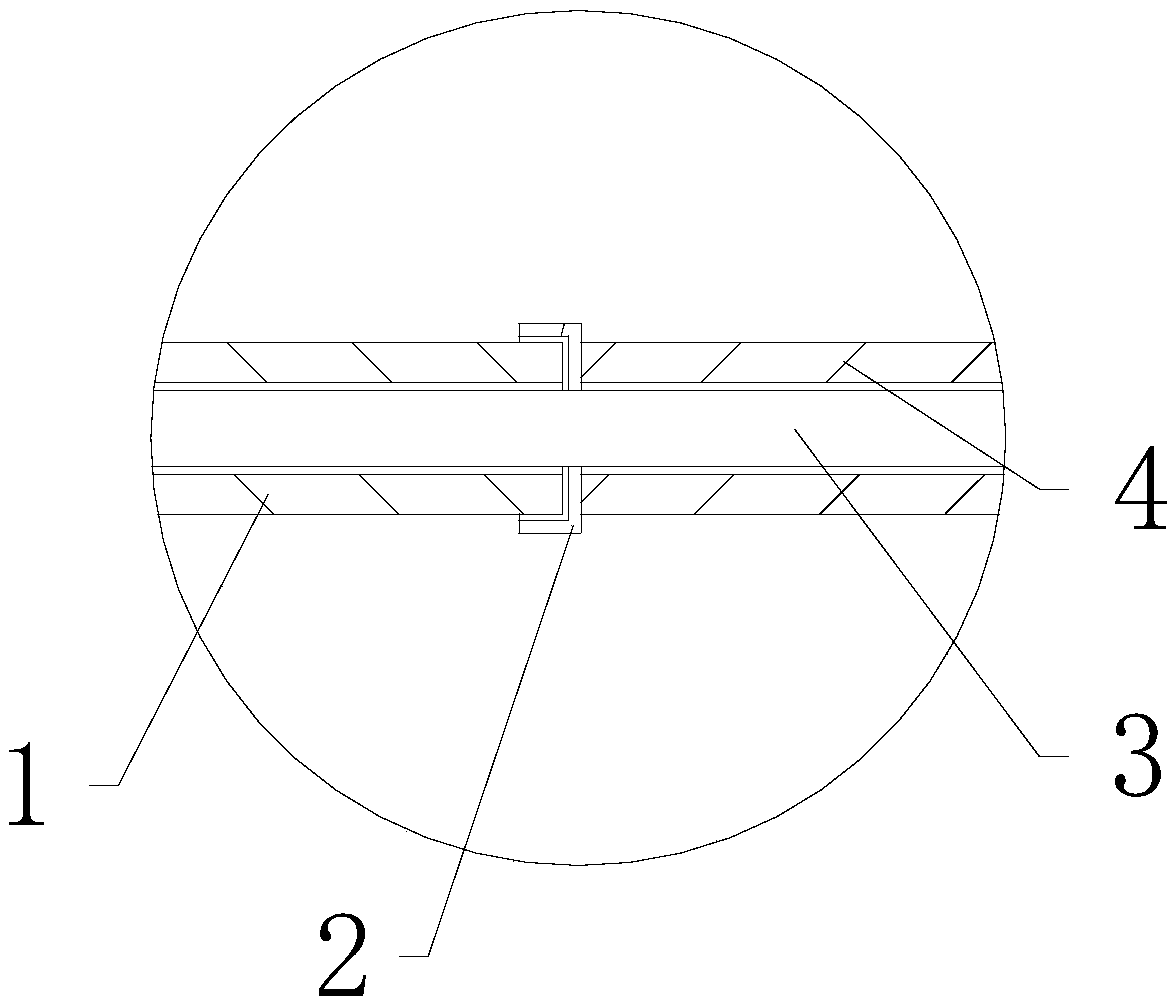

[0019] Specific implementation: in actual use, the user moves the moving wheel 6 along the hollow tube, so that the distance between the two moving wheels 6 is equal to the inner diameter of the pipe, and then turns the locking bolt to fix the moving wheel 6 , and then the user puts the detection robot body 5 and the moving wheel 6 into the pipe body 9, and then the user holds the connecting rod 2 3 and moves to the right, the connecting rod 2 3 moves to the right to drive the baffle plate 10 to move to the right, and the baffle plate 10 moves to the right. The plate 10 moves to the right so as to be in contact with the detection robot body 5, and drives the detection robot body 5 to move to the right. Moving to the right, the connecting rod one 1 moves to the right to drive the connecting rod two 3, the baffle plate 10 and the detection robot body 5 to move to the right, and the detection robot body 5 moves to the right to drive the collection box 8 to move to the right, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com