Flexible automatic production line for punching, welding or bonding of automobile exterior trimming parts

An automated production line, flexible bonding technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of no development work, no flexible automated production line, no complete set of punching and welding production line, etc., to achieve Improve equipment utilization, improve space utilization, and design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

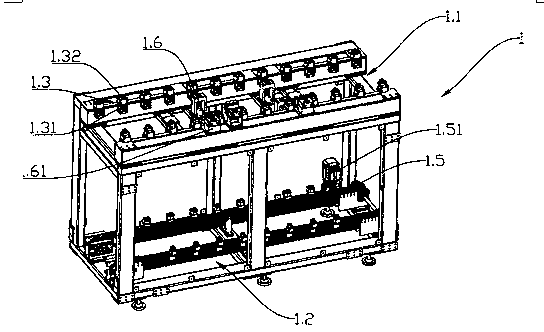

[0035] Such as Figure 1-9 shown, where figure 1 It is a structural schematic diagram of a preferred embodiment of the present invention, figure 2 It is a structural schematic diagram of another preferred embodiment of the present invention.

[0036] A flexible automatic production line for punching, welding or bonding automotive exterior parts, including a double-layer conveying platform 1 for conveying workpiece mounting seats and loading and unloading devices 2 arranged at both ends of the double-layer conveying platform 1, the double-layer conveying The side of the platform 1 is also provided with a robot punching system and / or a robot welding / bonding system, and the production line also includes a control system. The welding / bonding system is connected with the control system, and is used to receive the control system instructions to realize precise processing. In actual production, multiple corresponding robot punching systems and / or robot welding / bonding systems can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com