Roller changing mechanism of straightener

A roll changing mechanism and straightening machine technology, applied in the field of straightening machines, can solve the problems of time-consuming, laborious and low efficiency, and achieve the effects of accurate positioning, improving efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

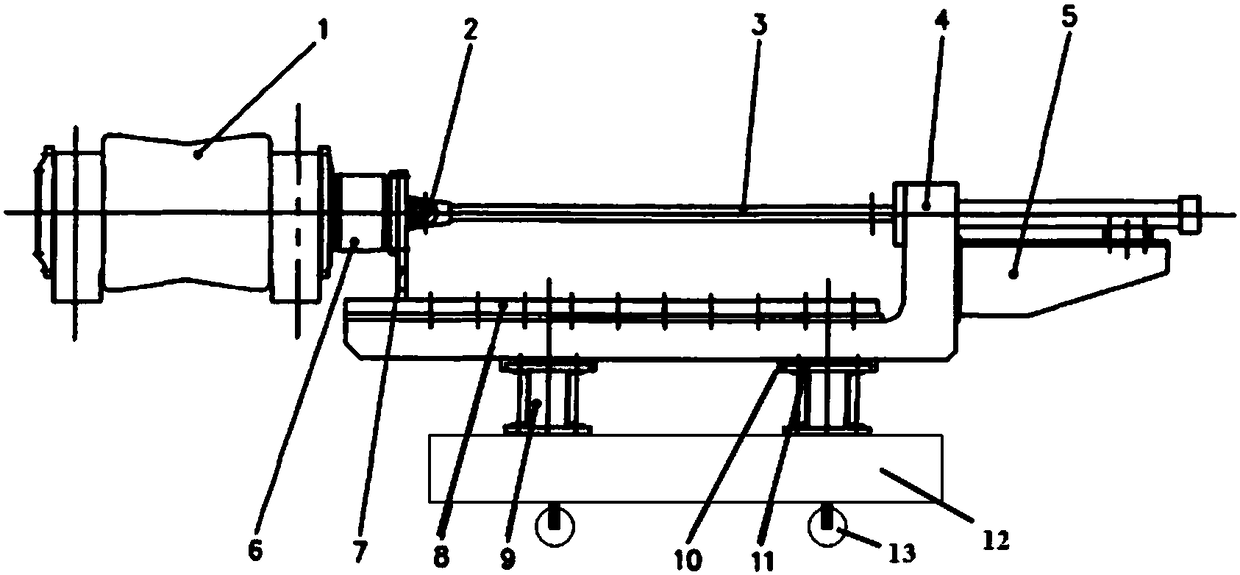

[0012] The present invention includes a support body 4, on which a moving device is arranged, and a support positioning device is connected to one end of the support body. The mobile device includes a connection support 7, a connection plate 8, a base 9, a support slide plate 10 and a base slide plate 11, the connection support 7 is installed on the connection plate 8, the connection plate 8 is fixed on the support body 4, and the support slide plate 10 and the base slide plate 11 are fastened together, and the support slide plate is welded on the bottom of the support body, and the base slide plate is welded on the base. The support positioning device includes a support 5, a limit baffle and a locking pin, the support is welded on the support body, the support has a locking pin, and the limit baffle is fixed on the support by bolts. The lower end of the base 9 is provided with a hydraulic lifting platform 12, the lower end of the hydraulic lifting platform 12 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com