Device for clearing molten aluminum at liquid injecting opening of casting material cylinder

A technology for removing devices and barrels, used in casting equipment, casting melt containers, manufacturing tools, etc., can solve problems such as obstruction of the pouring port, affecting the pouring of molten aluminum, and condensation in the pouring port, so as to avoid burns by high-temperature steam. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

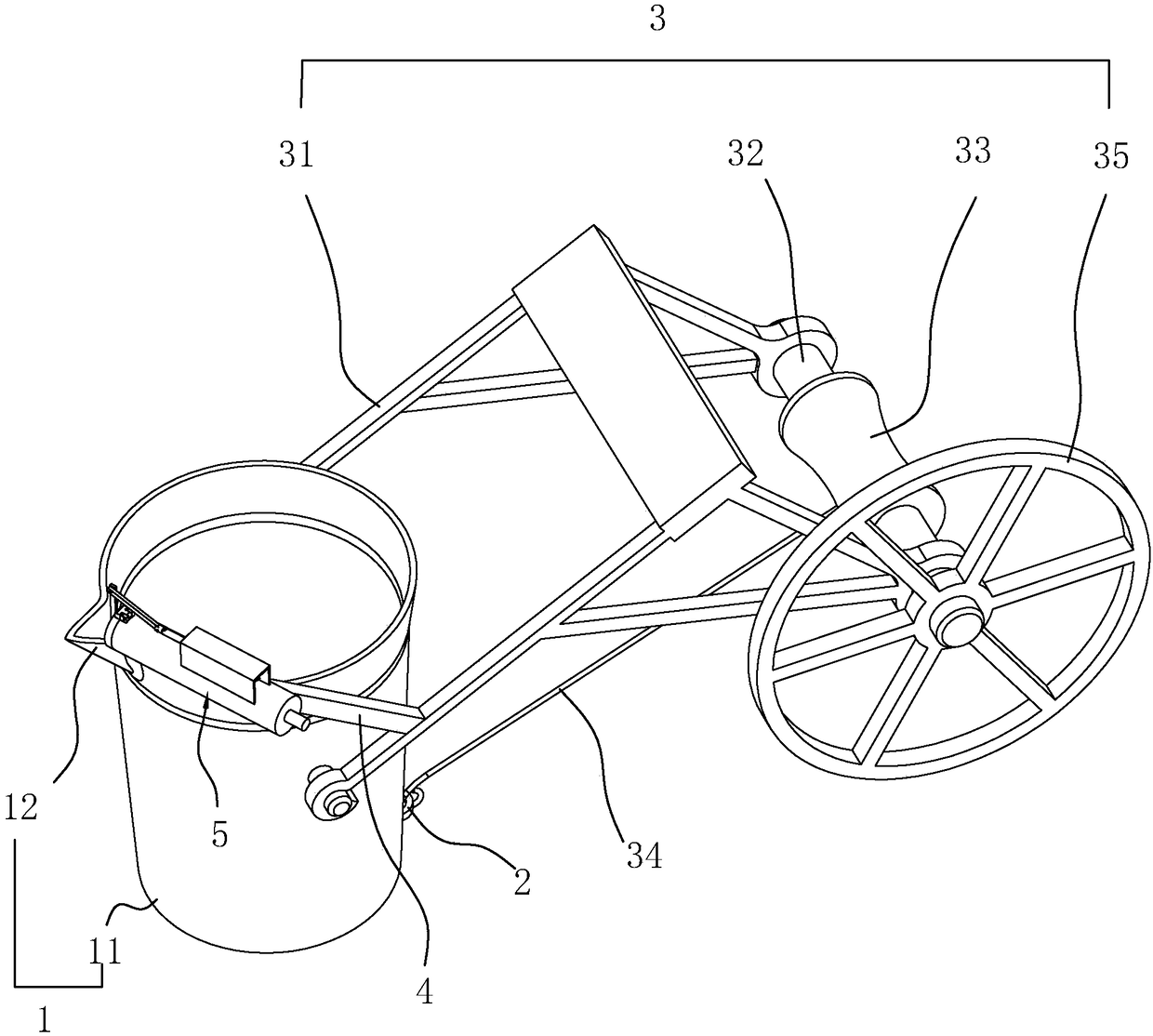

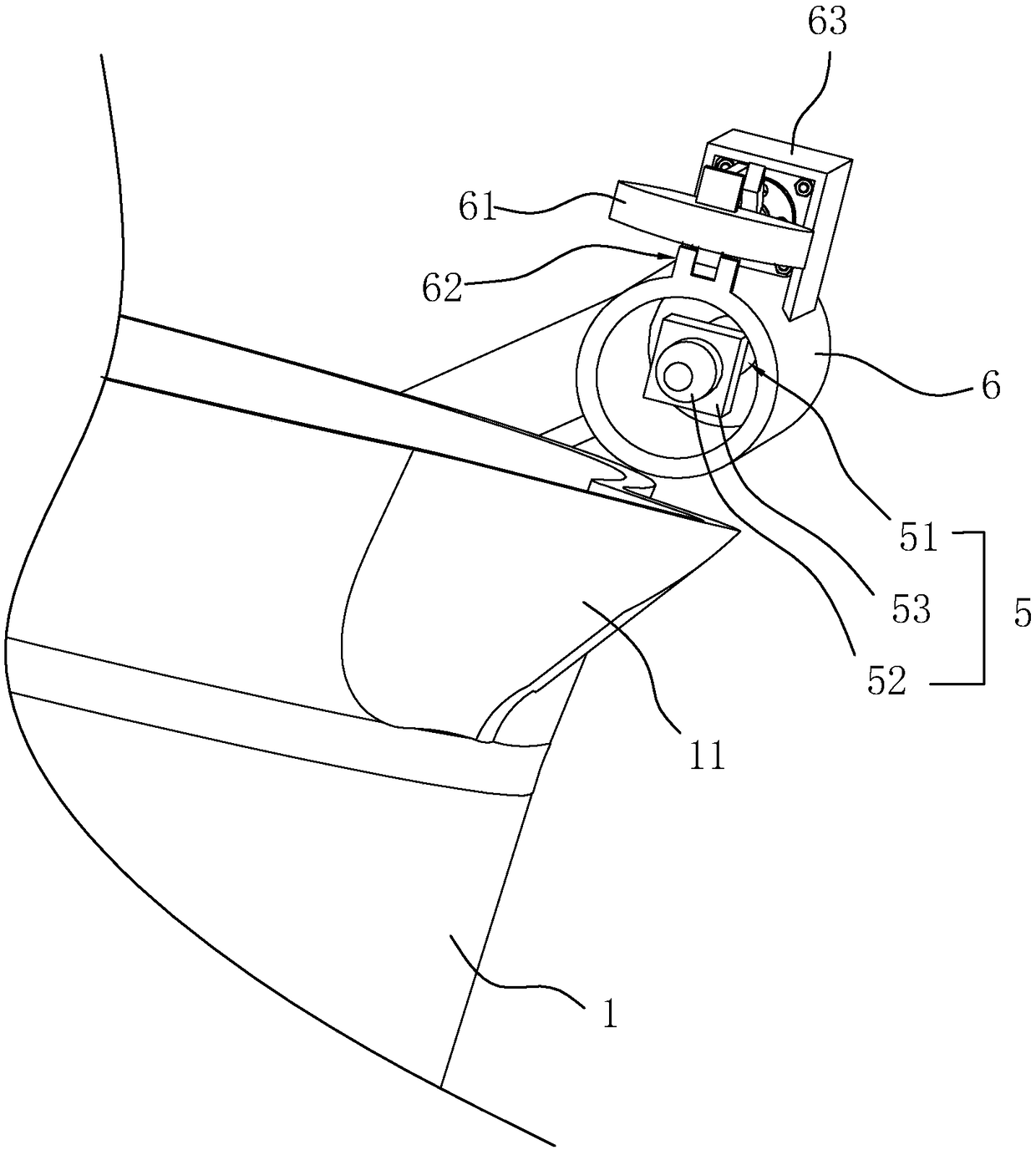

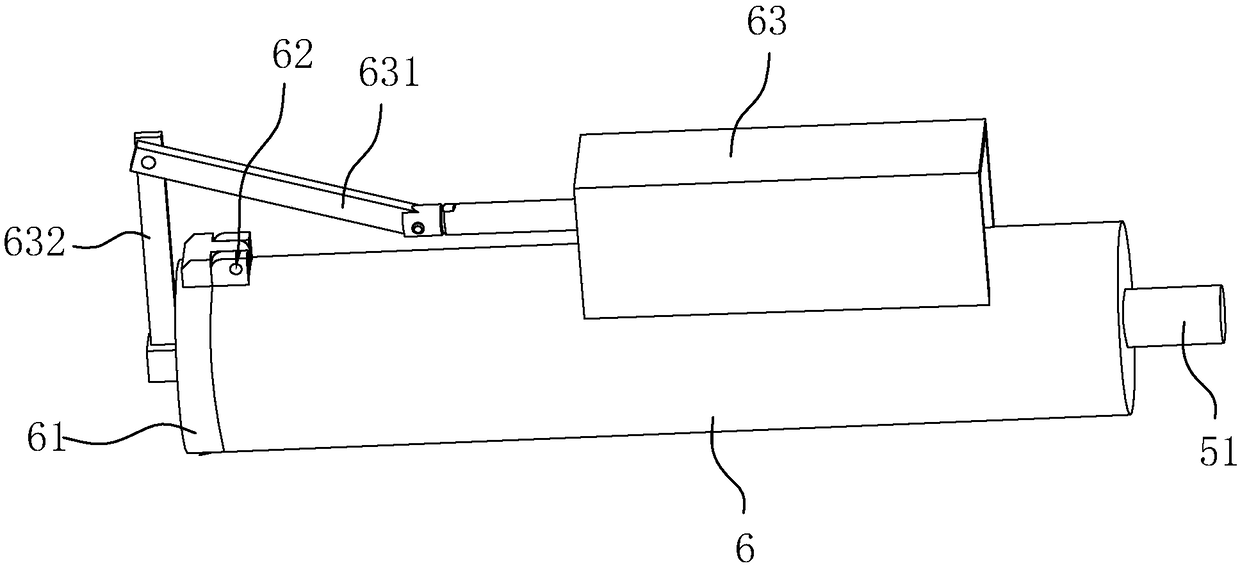

[0027] Example: refer to figure 1 , is the liquid aluminum removal device for the casting barrel soup injection port disclosed by the present invention. The barrel 1 includes a barrel body 11 and a soup injection port 12 located at the mouth of the barrel. A casting mold is placed under the barrel 1. The barrel 1 passes through the turning mechanism 3 control, can be turned over, and the aluminum liquid in it is poured into the casting mold along the soup injection port 12.

[0028] Turning mechanism 3 comprises a pair of connecting arms 31 hinged with the outer wall of barrel 1, connecting arms 31 are distributed on both sides of barrel 1 outer wall, one end of connecting arms 31 away from barrel 1 is connected by rotating shaft 32, and rotating shaft 32 is provided with Take-up reel 33, on the take-up reel 33 is wound with overturning line 34, overturning line 34 one end and the hook 2 that the tube bottom place of barrel 1 is provided with is fixed, and the shaft end of rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com