Left and right front longitudinal beam outer panel drawing die

A front longitudinal beam and drawing die technology, which is applied to forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easy occurrence of wrinkles, high resilience, easy generation of defective products and defective products, etc., so as to improve the qualified efficiency, improve production efficiency, and avoid the effect of springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

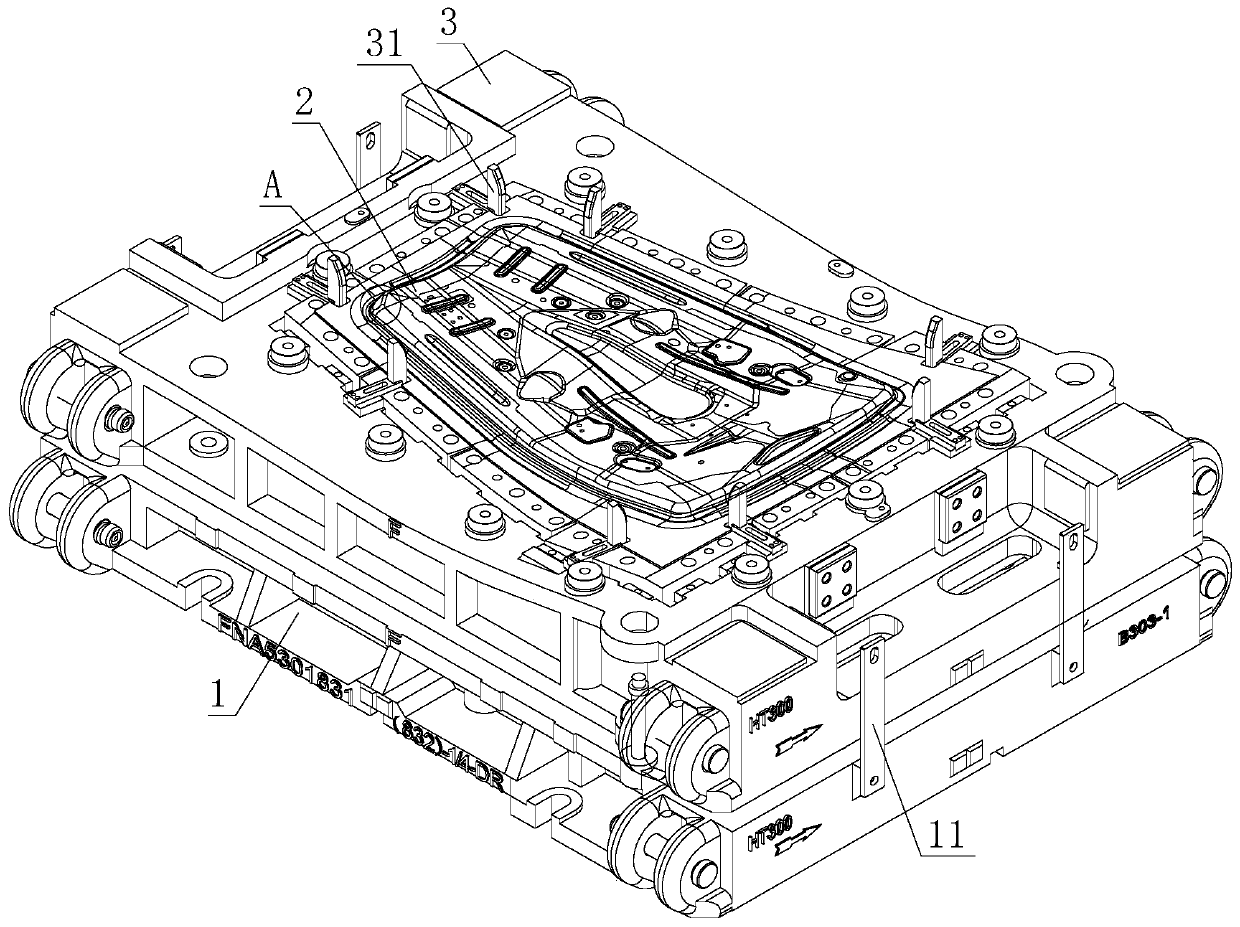

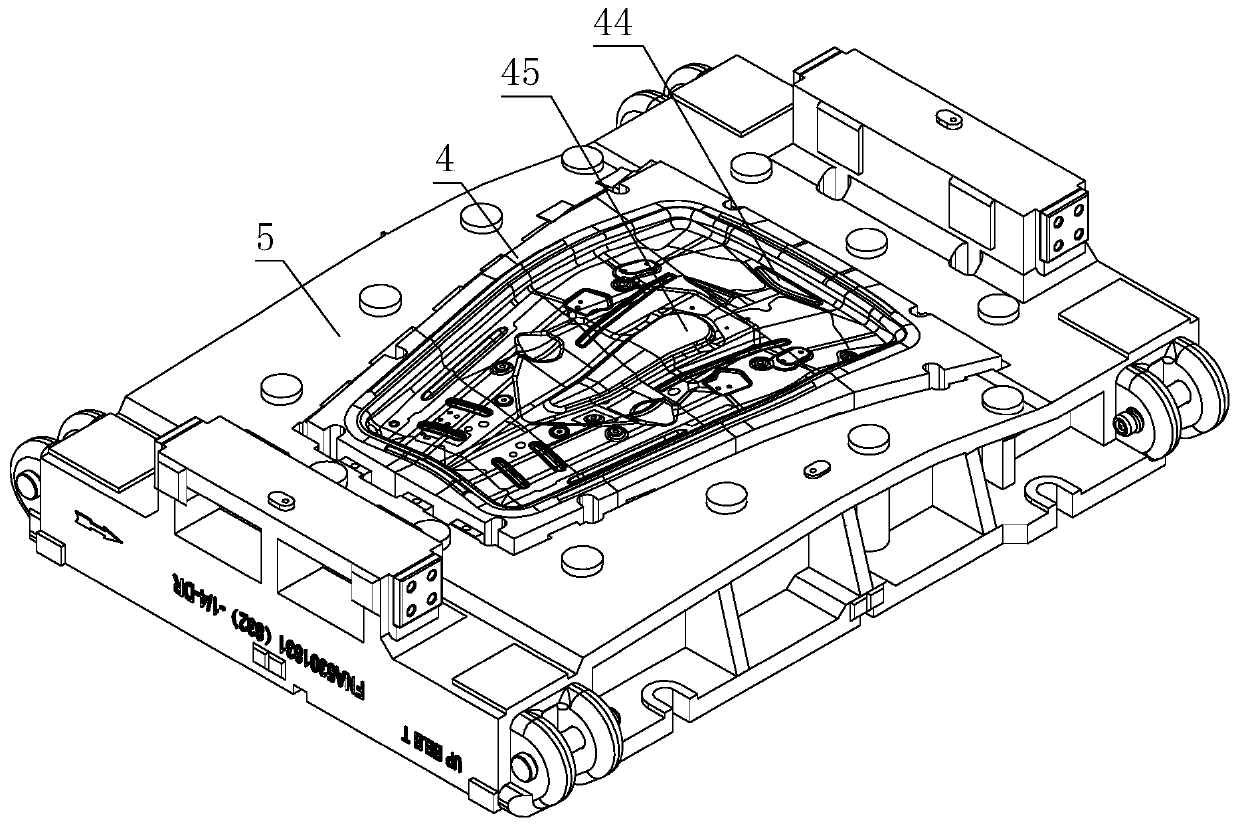

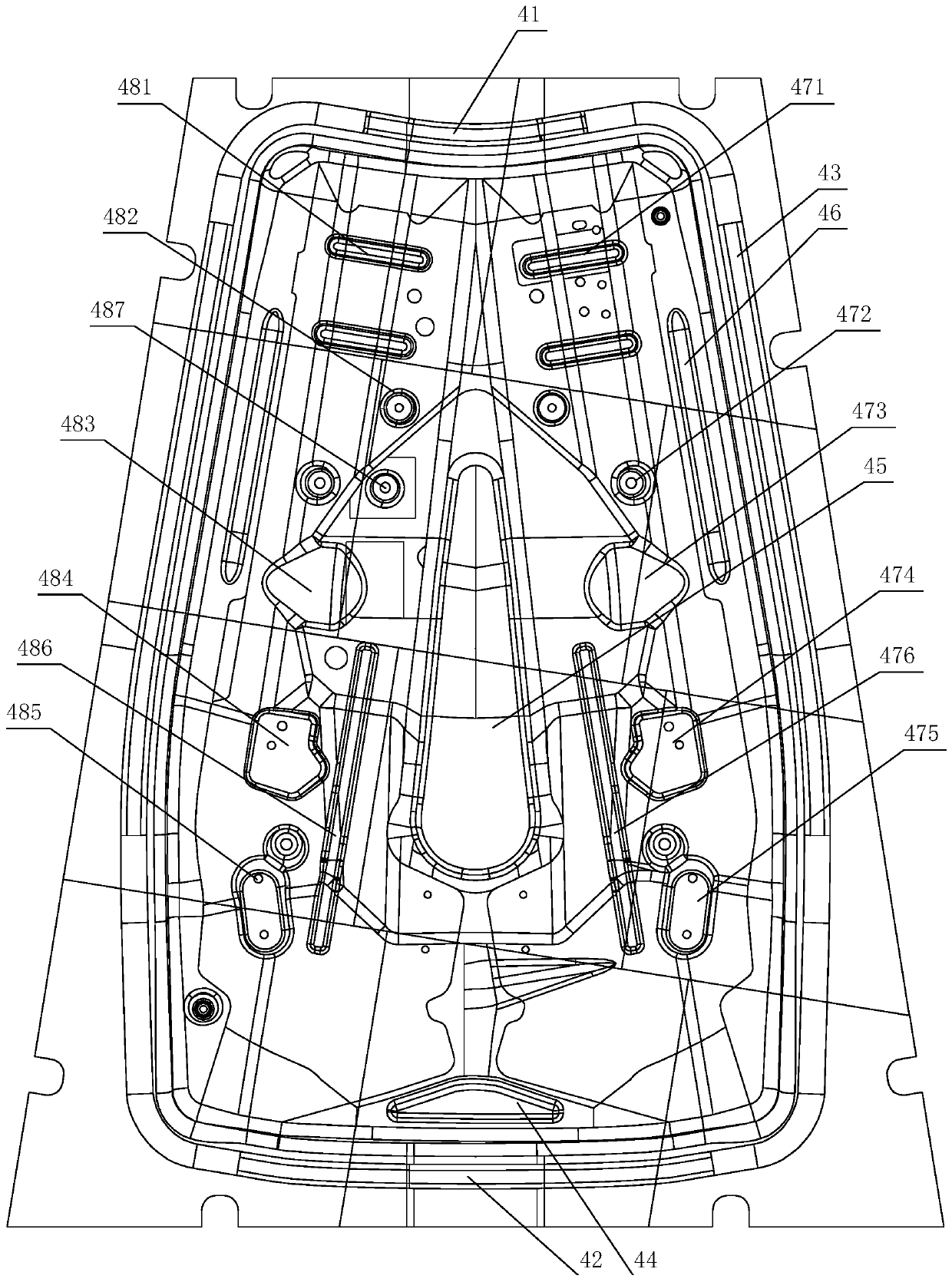

[0019] Such as Figure 1 to Figure 3 As shown, the preferred embodiment of the present invention's left and right front longitudinal beam outer panel drawing dies comprises an upper die holder 5, an upper die cutter 4, a blank holder 3, a punch holder 2 and a lower die holder 1, and the upper die cutter 4 is set on the upper die base 5, the punch base 2 is set on the lower die base 1, and the blank holder 3 is sleeved on the punch base 2 and supported by the lower die base 1. A limiting member 31 is arranged on the blank holder 3 . The upper mold knife 4 is provided with a slot for accommodating the limiting member 31, which effectively limits the raw material and realizes rapid positioning. The lower mold base 1 is provided with a connecting piece 11, and the connecting piece 11 can be fixed with the upper mold base 5 by bolts; the blank holder 3 is provided with a posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com