Oil-gas recovery device and method in cleaning process of storage tank in petro station

The technology of a recovery device and a gas station is applied in the field of oil and gas recovery devices in the process of clearing storage tanks in gas stations, which can solve the problems of direct discharge of oil and gas into the atmosphere and potential safety hazards, and achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

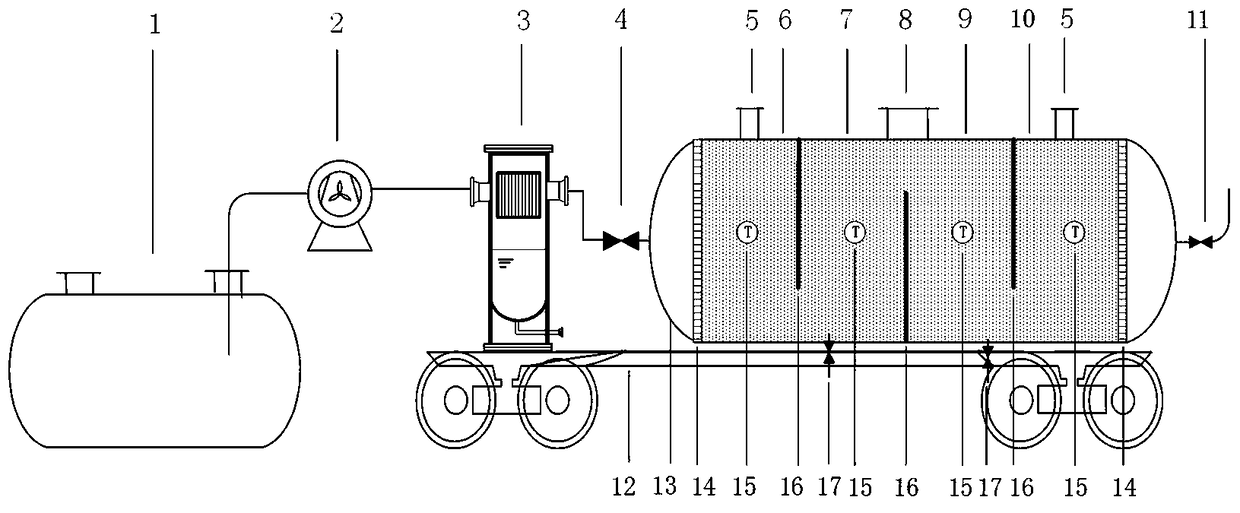

[0029] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0030] An oil and gas recovery device in the process of clearing a storage tank in a gas station, comprising a frequency conversion fan 2, a feather-blade gas-liquid separator 3 connected with the frequency-conversion fan 2, and a horizontal activated carbon connected with the feather-blade gas-liquid separator 3 Tank 13, the two ends of the horizontal activated carbon tank 13 are respectively provided with an inlet hand valve 4 and an outlet hand valve 11, the top is provided with a carbon filling port 5 and a manhole 8, a baffle 16 and a thermometer 15 are provided inside, and the lower part is provided with a guide. The hand shower valve 17 regularly discharges the liquid accumulated in the horizontal activated carbon canister 13 .

[0031] Gas distribution plates 14 are provided at both ends of the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com