Shoes and production process thereof

A technology for shoes and shoe uppers, which is applied to the field of shoes and their production processes, can solve the problems of cumbersome and complicated production and processing processes, open glue between soles and uppers, and shorten the service life of shoes, so as to achieve convenient and fast production and processing processes and increase wearing service life. , The effect of wearing process is convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

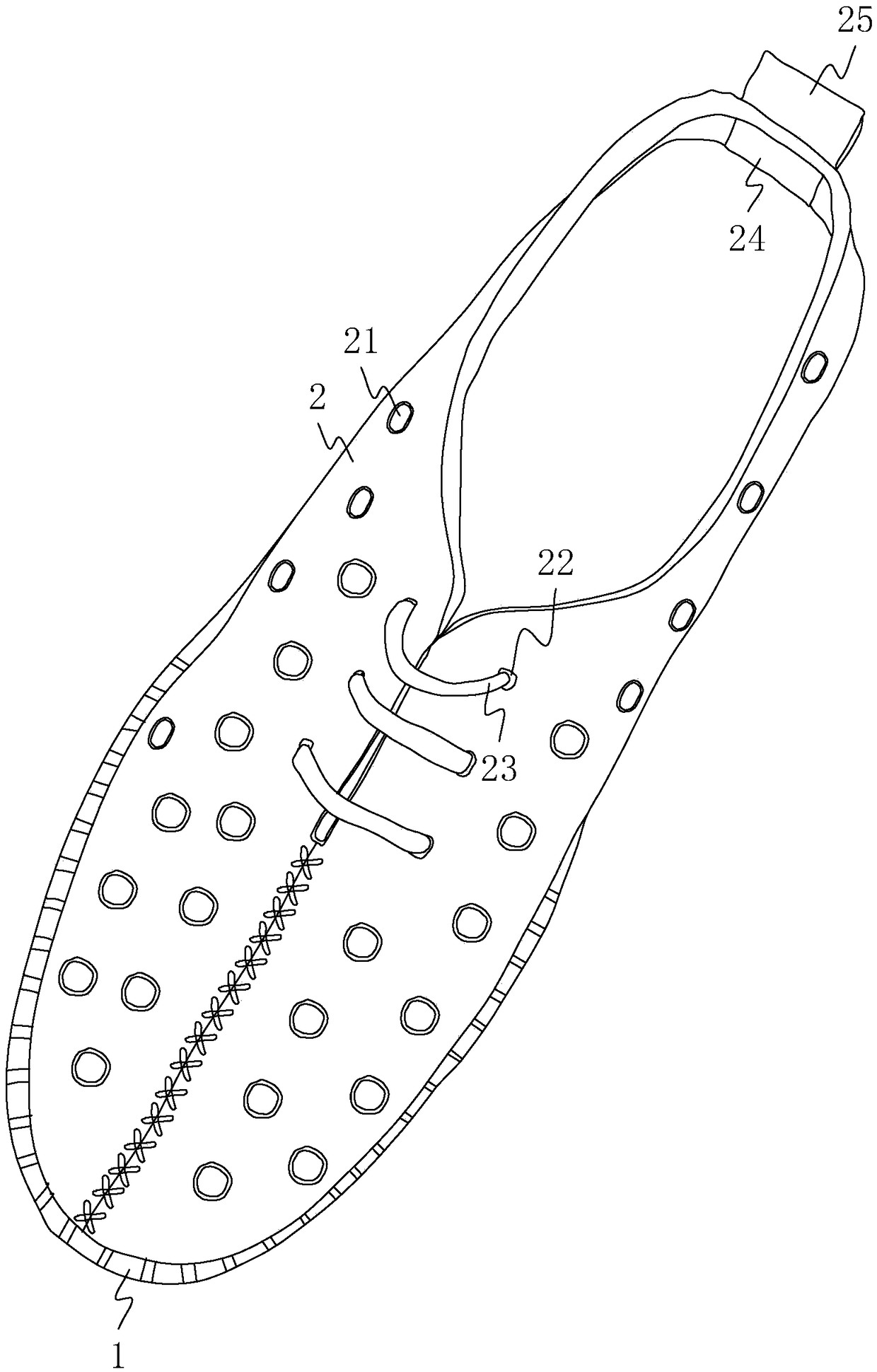

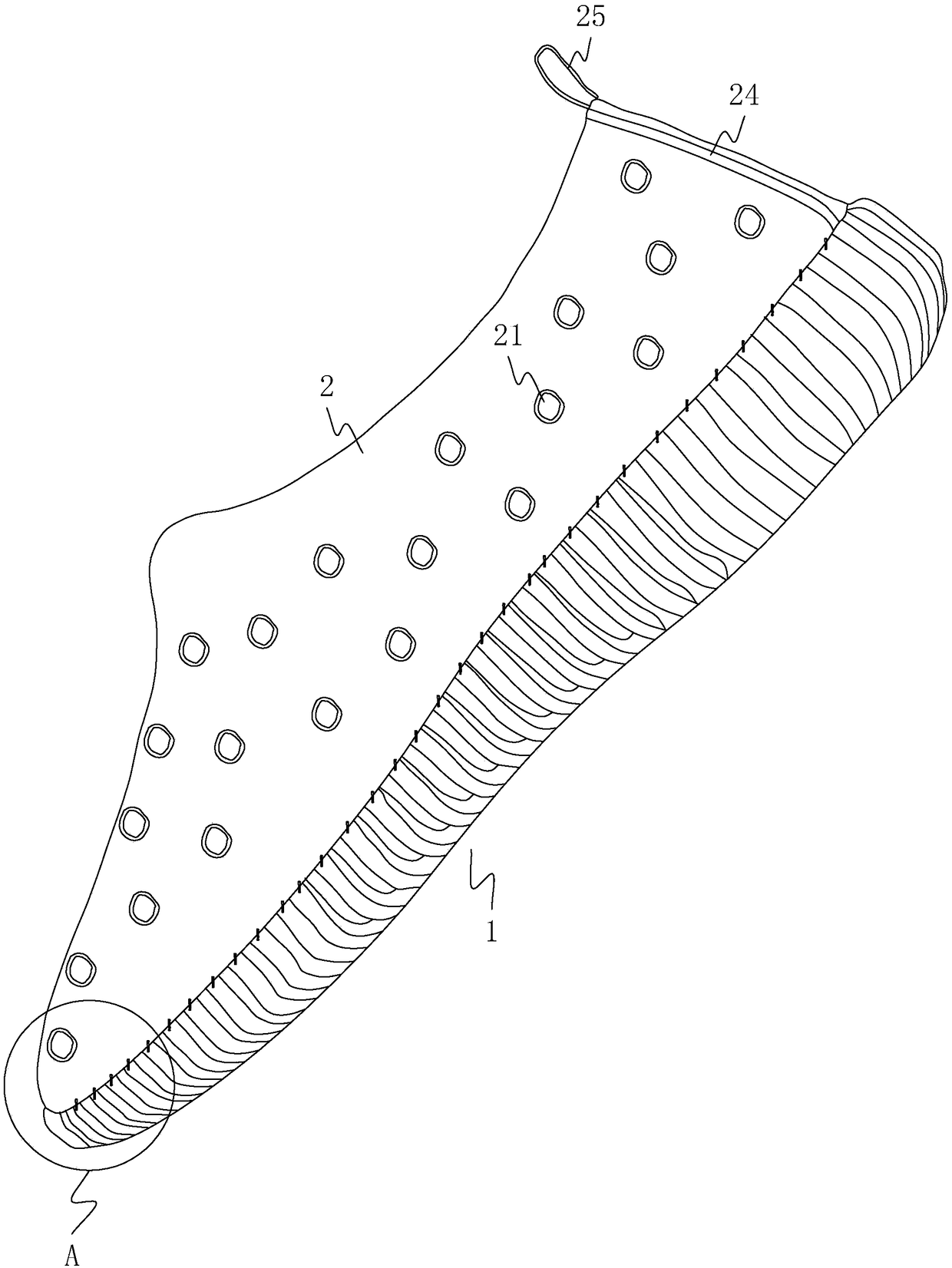

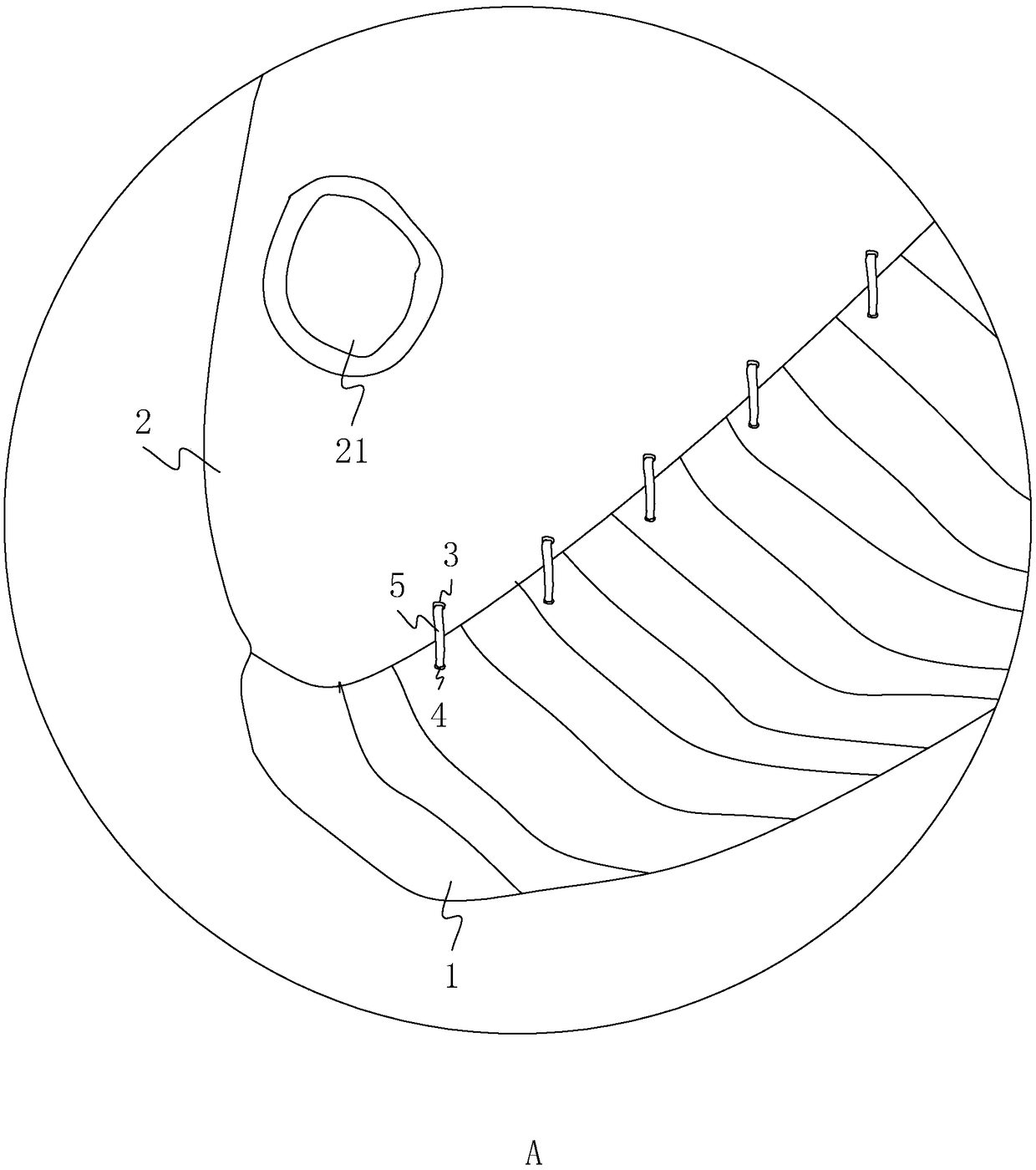

[0042] Embodiment 1: a kind of shoes, such as figure 1 As shown, it includes a shoe sole 1 and a pair of shoe uppers 2 arranged symmetrically to each other. A pair of shoe uppers 2 are penetrated with a number of air holes 21. A pair of shoe uppers 2 are provided with shoe eyes 22, and shoe eyelets 22 are provided with elastic shoelaces 23. , an elastic tongue (not shown in the figure) covering the elastic shoelace 23 is provided on the inner wall of a pair of shoe uppers 2 .

[0043] When wearing the above shoes, pull a pair of uppers 2 away from each other. At this time, a pair of uppers 2 pull the elastic shoelace 23 and elastic tongue to deform elastically, and then put the foot into the cavity before the sole 1 and the upper 2. , loosen a pair of uppers 2, and now the elastic shoelaces 23 and the elastic tongue shrink, and at the same time drive a pair of uppers 2 close to each other and press against the side of the foot, so the wearing process of the shoes is convenient...

Embodiment 2

[0054] Embodiment 2: a kind of production technology of producing above-mentioned shoes, comprises the following steps:

[0055] S1: Using an injection molding machine to inject the sole into shape;

[0056] S2: using a punching machine to punch holes in the first sewing hole of the sole;

[0057] S3: Stack multiple blanks of the upper, and use a punching machine to punch holes for the second stitching hole, eyelets and air holes of the upper;

[0058] S4: cutting the blank of the upper;

[0059] S5: Install the elastic shoelace in the eyelet, sew a pair of uppers with sewing thread, and sew the tongue, patch and handle to the upper at the same time;

[0060] S6: Use sewing rope to sew the sole and the upper together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com