Verticality measuring device and verticality control system

A measuring device and technology of perpendicularity, applied in the direction of plumb line, etc., can solve problems such as inaccurate measurement of perpendicularity, influence of observation effect, large deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

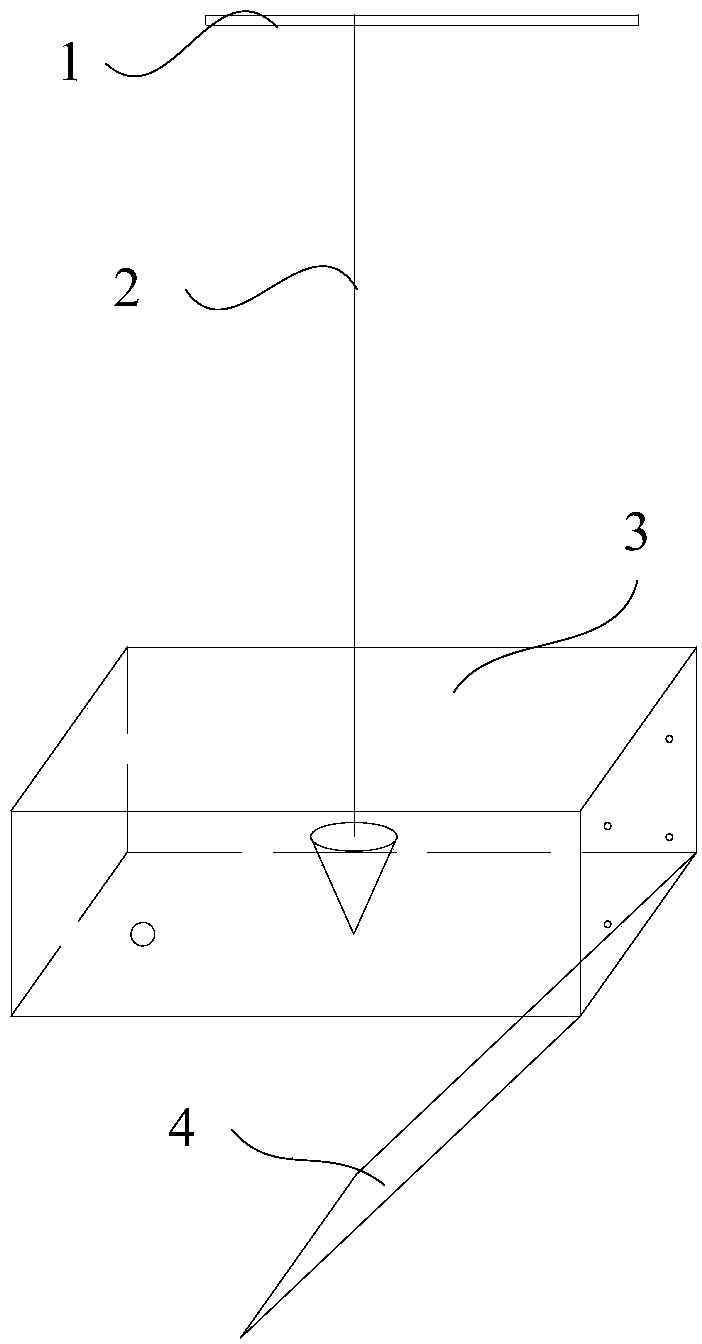

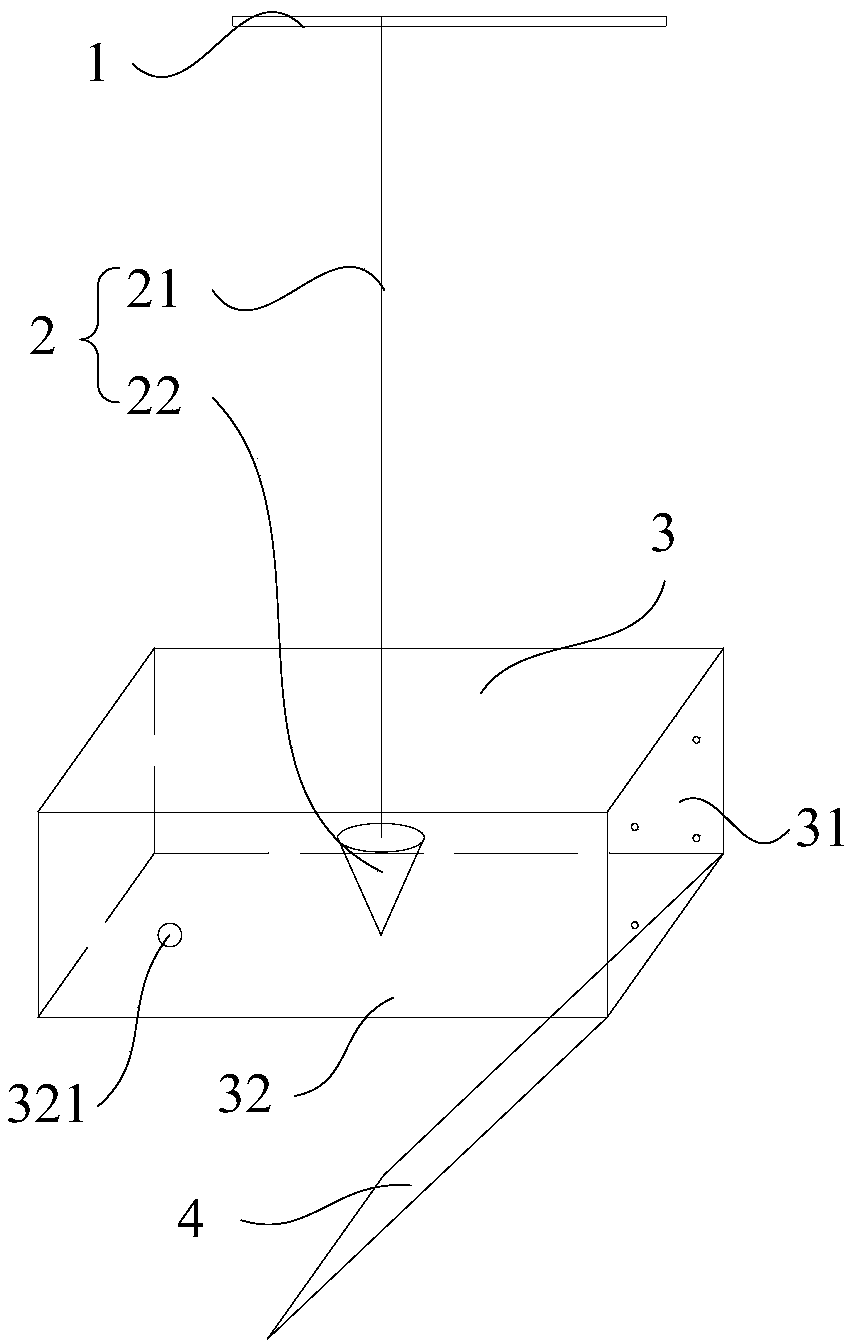

[0034] see Figure 1 to Figure 2 As shown, Embodiment 1 of the present application provides a kind of perpendicularity measuring device, comprises fixture 1, plumb 2, windproof box 3 and observation mirror 4; One end of one end is connected with the vertical ball 22; the fixing part 1 is respectively connected with the object to be tested and the other end of the suspension wire 21, so that the vertical ball 22 hangs down along the direction of gravity; the windproof box 3 is connected with the object to be tested, and the vertical ball 22 is located in the windproof box 3 Middle; observation mirror 4 is connected with windproof box 3.

[0035] In this embodiment, the perpendicularity measuring device provided by the present application includes a fixing piece 1 , a plumb 2 , a windproof box 3 and an observation mirror 4 . Wherein, the plumb 2 includes a suspension wire 21 and a plumb ball 22. One end of the suspension wire 21 is connected to the fixture 1, and the other end ...

Embodiment 2

[0056] The perpendicularity measuring device in the second embodiment is an improvement on the basis of the first embodiment. The technical content disclosed in the first embodiment will not be described repeatedly, and the content disclosed in the first embodiment also belongs to the content disclosed in the second embodiment.

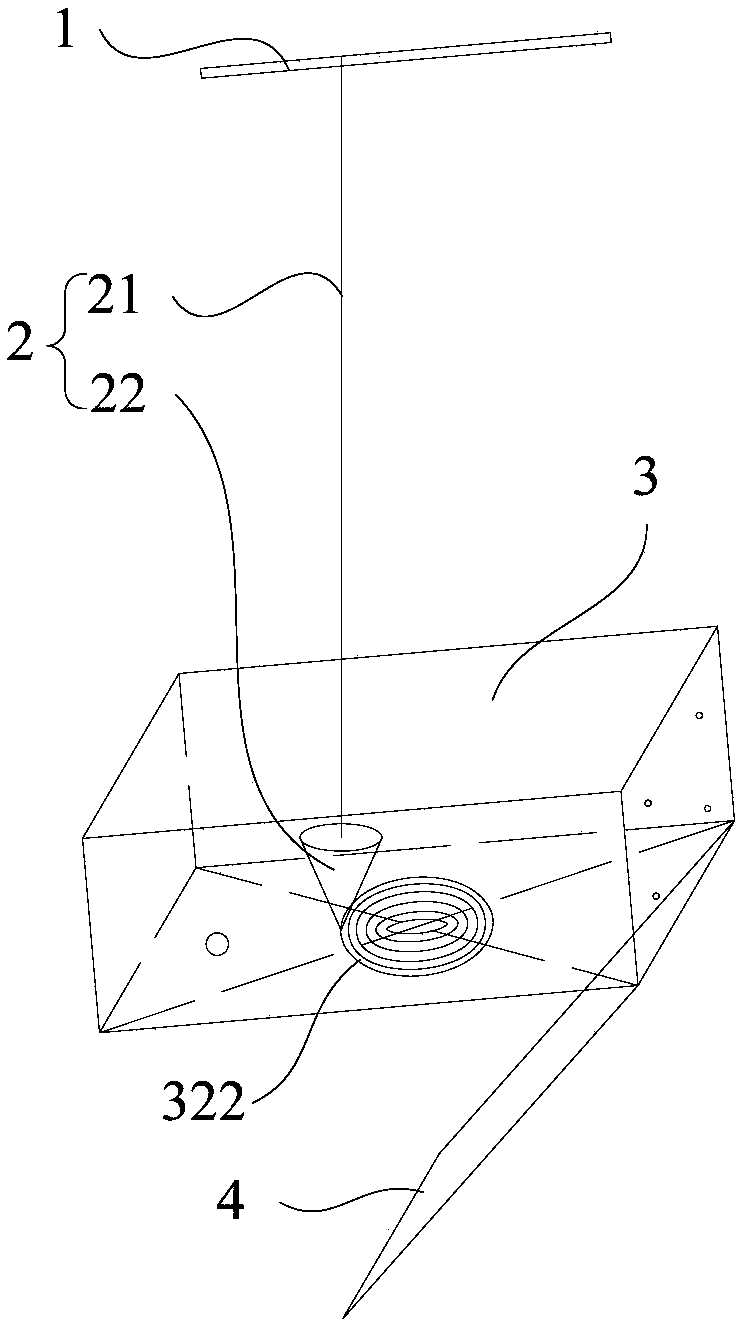

[0057] see Figure 3 to Figure 4 As shown, in this embodiment, a scale line 322 is provided on the bottom surface 32 of the open box, and there is a tip structure below the plumb ball 22, and the tip structure points to the specific position of the scale line 322 for measuring the verticality of the object to be tested.

[0058] Specifically, the present application sets a scale line 322 on the bottom surface 32 of the open box, and the lower end of the drop ball 22 has a tip structure, and the specific position where the tip structure of the drop ball 22 points to the scale line 322 can reflect the verticality of the object to be tested. In the state...

Embodiment 3

[0065] Embodiment 3 of the present application provides a verticality control system, including the verticality measuring devices provided in Embodiment 1 and Embodiment 2. Therefore, it has all the beneficial technical effects of the device, which will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com