Method for testing profile accuracy of coated surface

A technology of precision testing and surface type, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of low multi-point efficiency, inability to meet the surface accuracy, and accuracy cannot be guaranteed, so as to avoid the risk of damage and improve Test efficiency and test accuracy, reduce the effect of surface accuracy measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

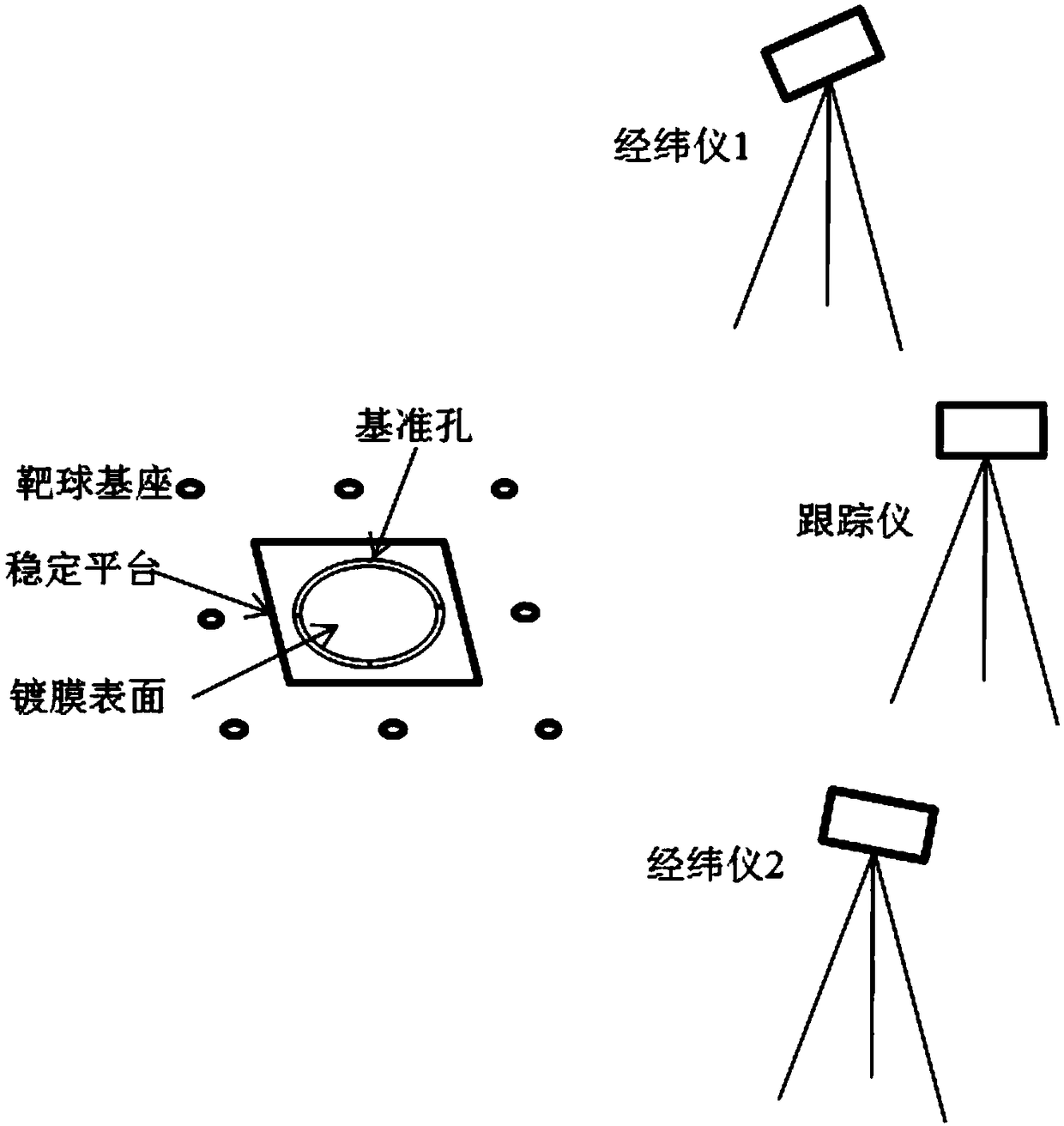

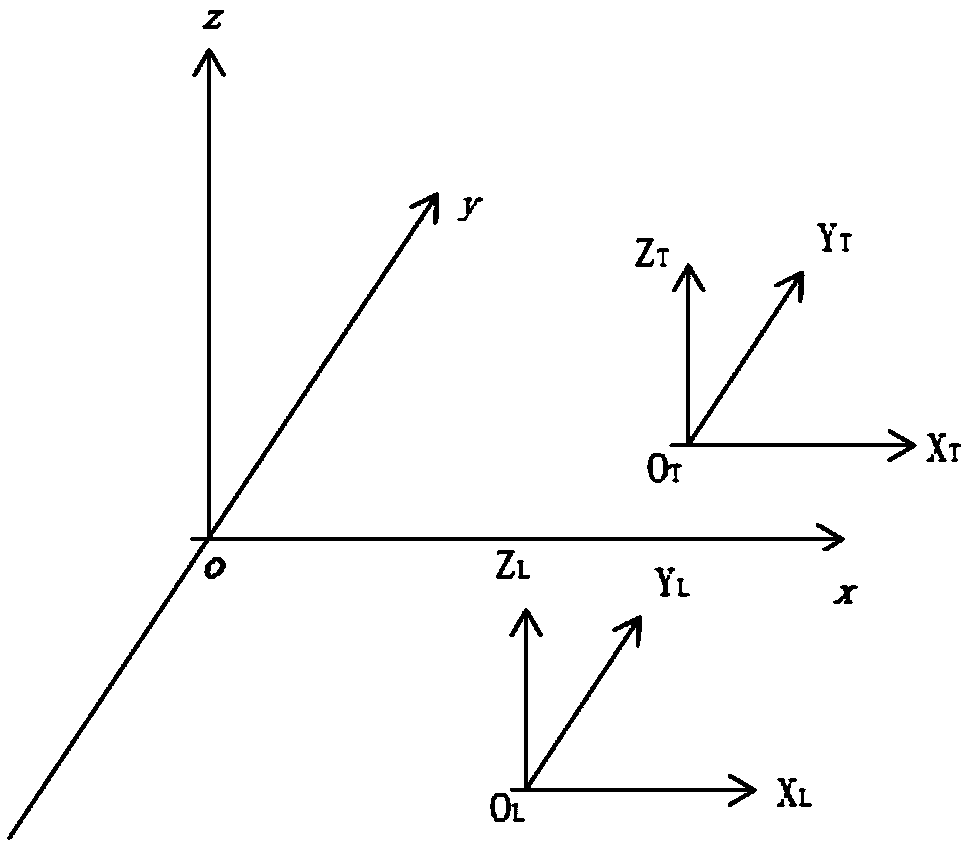

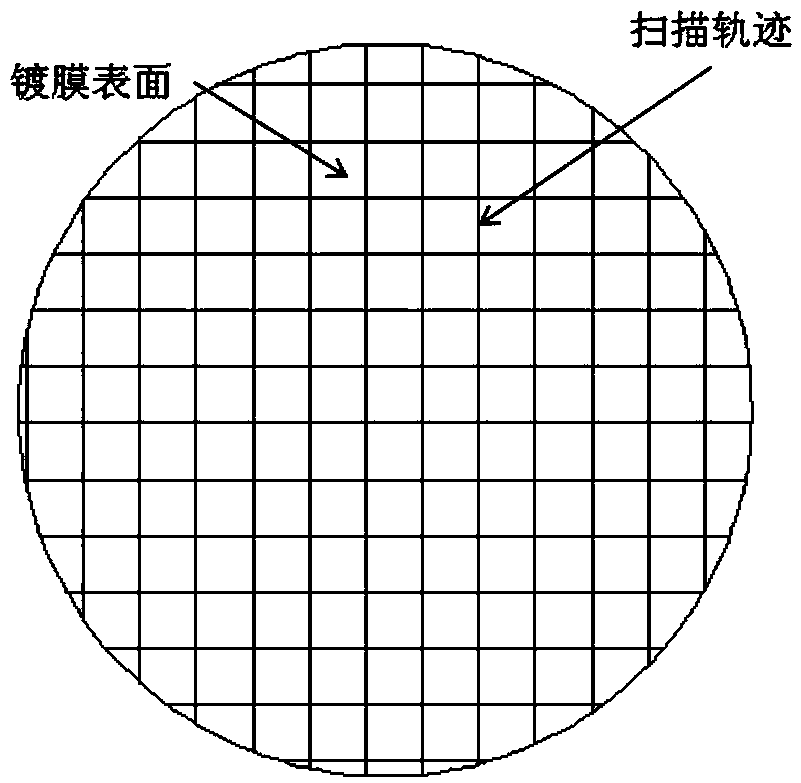

[0037] The invention provides a method for testing the accuracy of the coating surface profile. The method uses a laser tracking test system combined with a traditional double theodolite intersection measurement system to complete the spatial scanning measurement of the coating target surface profile accuracy on the basis of the conversion of the test reference. Through the target thickness compensation, the direct comparison measurement of the surface accuracy of the high-precision coating is realized, which avoids the risk of damage to the coating due to glue remaining at the pasting mark point, and at the same time greatly improves the test efficiency and accuracy.

[0038] The following is a detailed description with a specific example:

[0039] (1) Place the coated surface of the measured object on a stable platform without stress, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com