A fire valve closes the end effector of a firefighting robot

An end effector and valve technology, applied in valve details, valve devices, manipulators, etc., can solve the problems of no automatic valve closing device, complicated and difficult to observe valve conditions, and inability to close the valve, so as to shorten the clamping time. , Excellent fireproof and explosion-proof performance, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

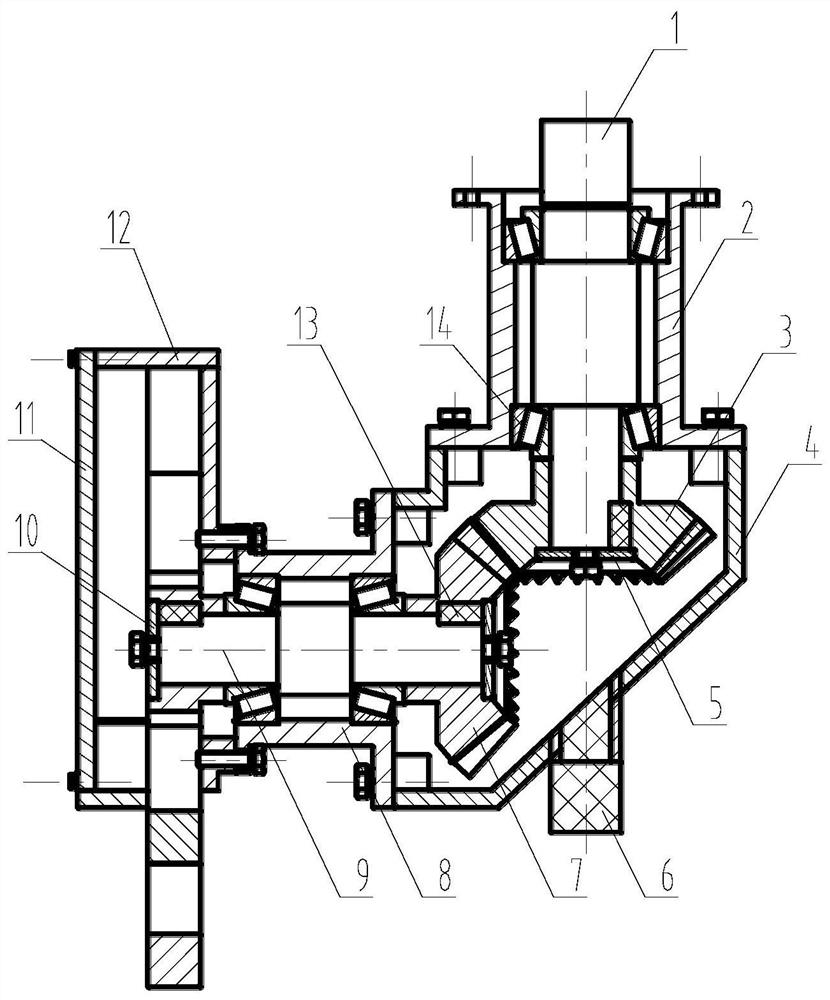

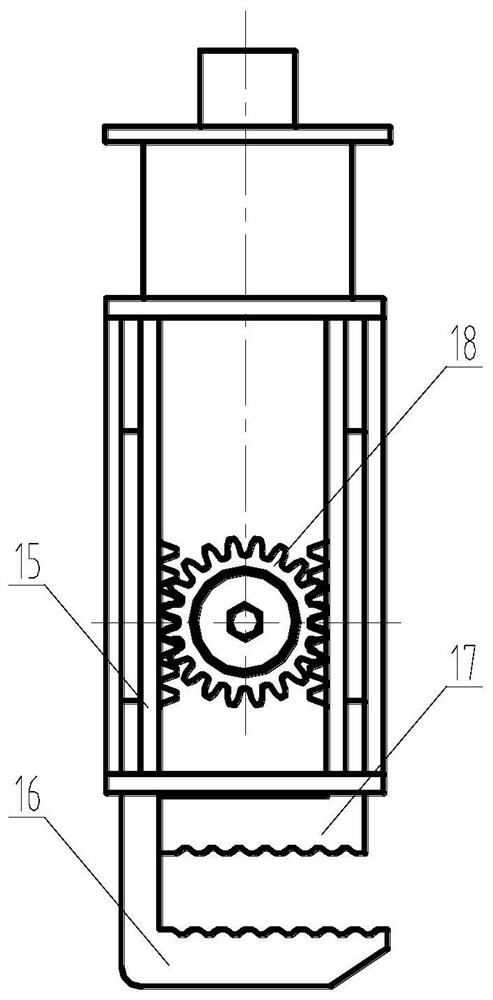

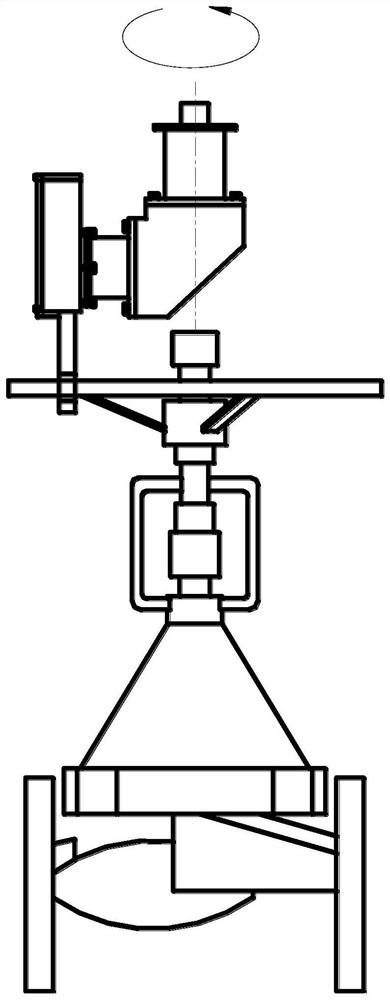

[0022] The invention as figure 1 , 2 As shown, the main components are input shaft 1, T-axis connector 2, input bevel gear 3, connector 4, end cover I5, high temperature resistant camera 6, output bevel gear 7, output shaft connector 8, output shaft 9, end Cover II 10, baffle plate 11, cover 12, key 13, tapered roller bearing 14, rack pressure plate 15, lower clamp body 16, upper clamp body 17, gear 18, etc. There is a spline groove in the input shaft 1 to connect with the input shaft of the external robot to transmit the main motion. The T-axis connecting body 2 is connected with the T-axis of the external robot through bolts, and drives the entire end effector to rotate 360° around the T-axis. The input bevel gear 3 and the output bevel gear 7 play the role of transmitting the rotary motion of the input shaft 1, and are respectively connected with the input shaft 1 and the output shaft 9 through the key 13, and the end cover I5 plays a role of restricting the input bevel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com