Pedal type hanging pile device suitable for hard soil construction

A pedal-type, wire-pile technology, applied in roads, buildings, road repairs, etc., can solve problems such as unqualified construction quality, time-consuming and labor-intensive, and losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

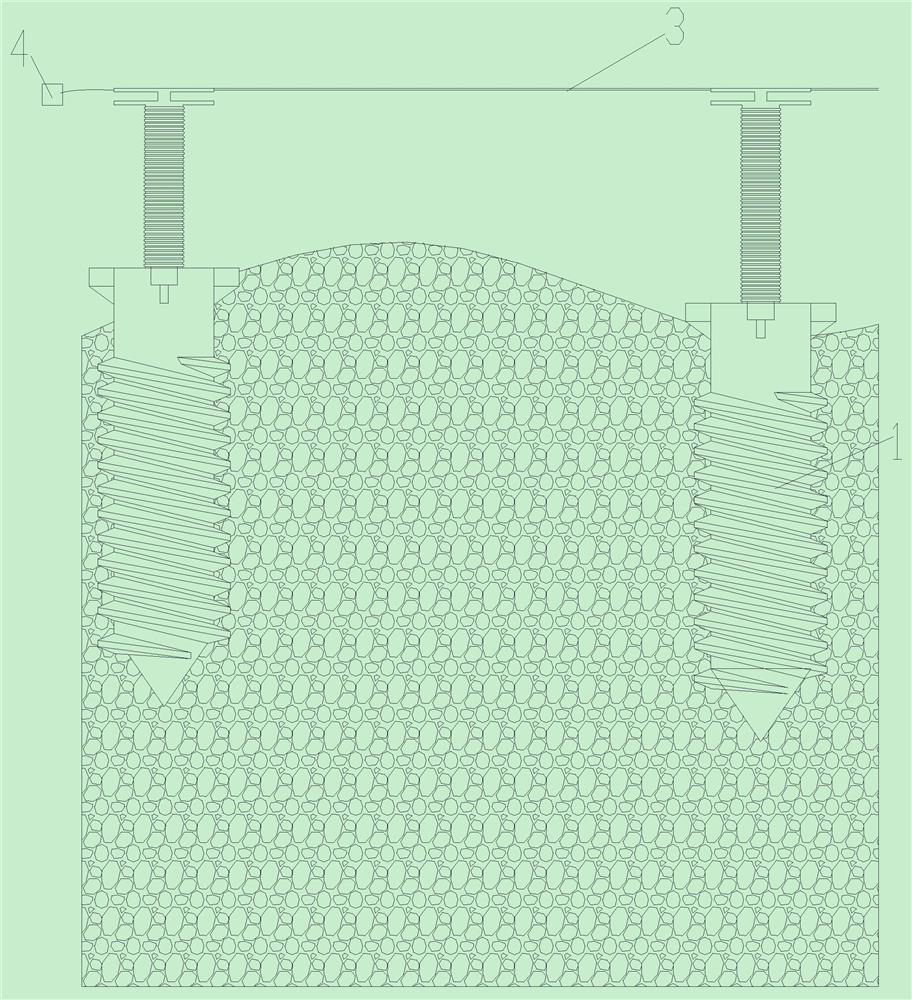

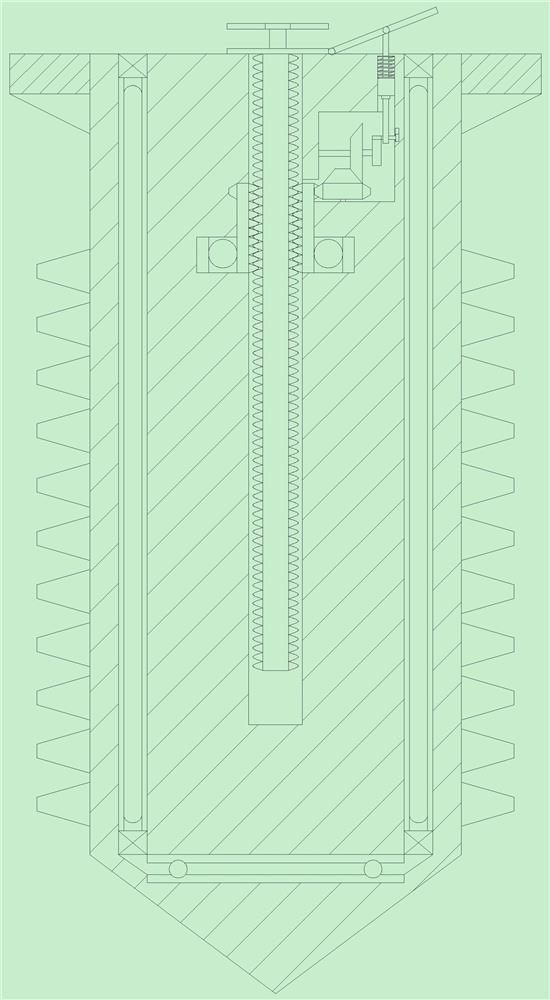

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a cross-sectional view of the foot-operated line stake of the present invention; image 3 It is a partially enlarged view of the foot-operated wire hanging pile of the present invention; Figure 4 It is a cross-sectional view of the foot-operated line stake of the present invention; Figure 5 It is a structural schematic diagram of the installation device of the present invention; Figure 6 It is a top view of the mounting device of the present invention; Figure 7 It is a sectional view of the mounting device of the present invention; Figure 8It is a partially enlarged view of the installation device of the present invention, as shown in the figure: a plurality of foot-operated hanging stakes 1 that are inserted into the road bed at intervals along the curb direction and can be adjusted in height according to the measured paving elevation data and connected to adjacent The wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com