Automatic detecting device of fabric thickness on sewing machine

An automatic detection device and sewing machine technology, applied in the direction of measuring device, sewing machine components, tension device, etc., can solve the problems of complex structure of detection device, many parts, easy to fail, etc., to meet the needs of intelligent adjustment, reduce position requirements, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

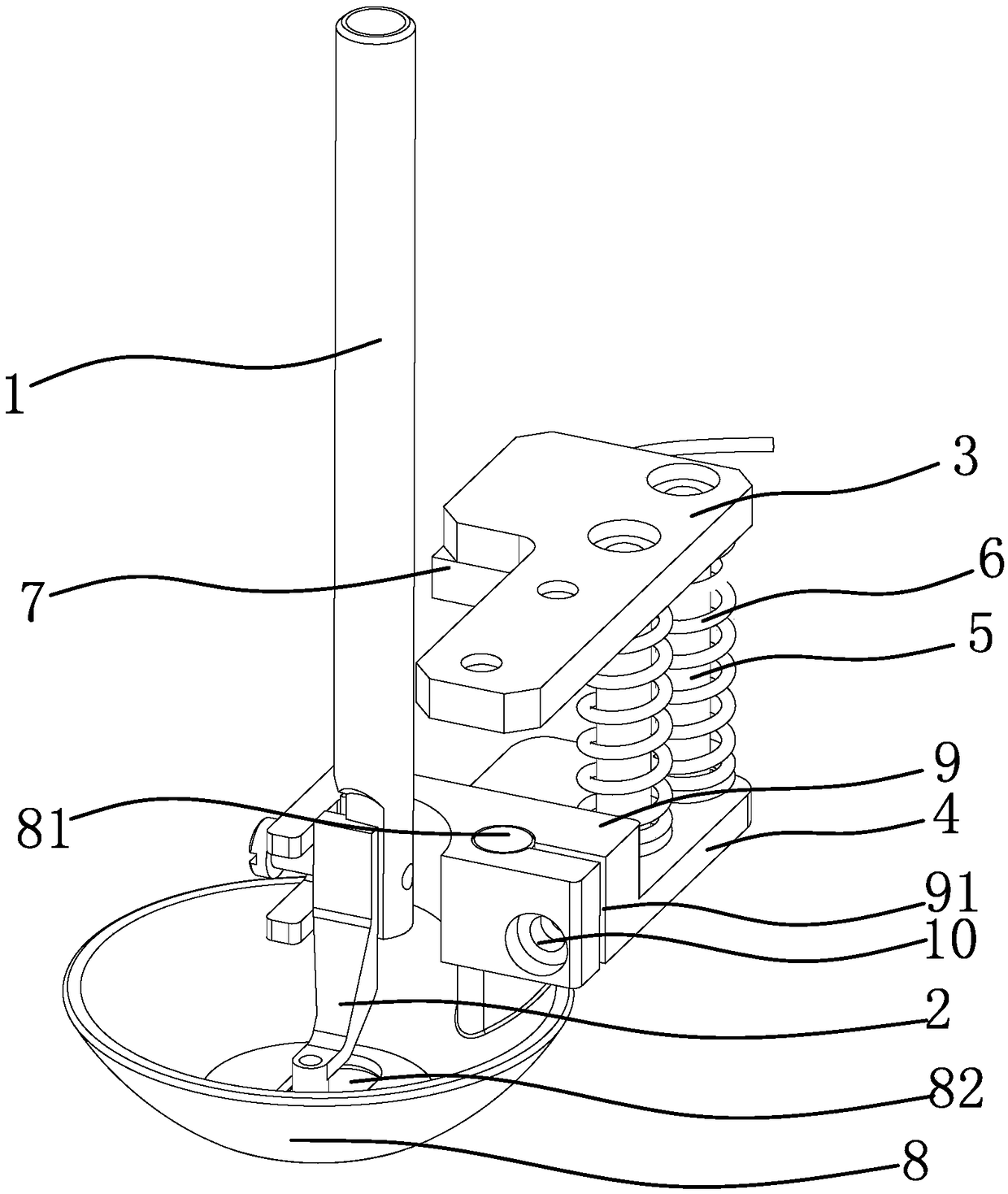

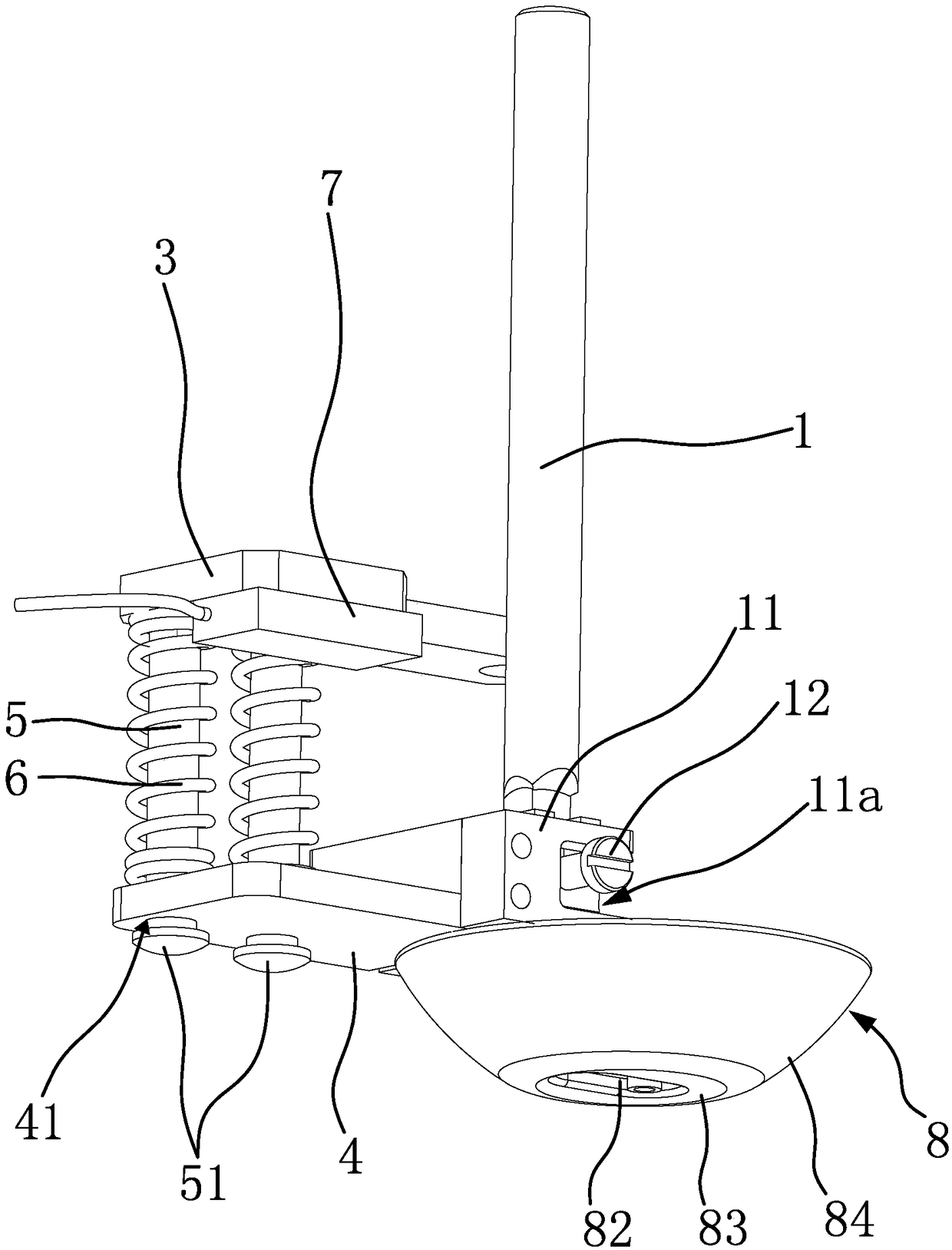

[0038] Such as figure 1 and figure 2 As shown, the sewing machine includes a pressing rod 1 and an intermediate presser foot 2 arranged at the lower end of the pressing rod 1. The automatic detection device includes a fixed plate 3 and a connecting plate 4 arranged at intervals up and down. The bottom of the fixed plate 3 is provided with a vertical Guide rod 5, connecting plate 4 is slidably sleeved on the guiding rod 5, and the guide rod 5 is also sleeved with a spring 6 and the two ends of the spring 6 respectively act on the bottom surface of the fixed plate 3 and the upper surface of the connecting plate 4; The bottom of 3 is also fixedly provided with the distance sensor 7 towards the connecting plate 4, certainly the distance sensor 7 also can be fixedly installed on the upper end surface of the connecting plate 4 and arranged towards the fixing plate 3; the connecting plate 4 is fixedly provided with a detection presser foot 8 , the detection presser foot 8 is locate...

Embodiment 2

[0044] A method for automatically adjusting the height of the middle presser foot 2 on a sewing machine is disclosed in this embodiment, as figure 1 and figure 2 As shown, the sewing machine includes a controller, a pressing rod 1, an intermediate presser foot 2 arranged at the lower end of the pressing rod 1, and a motor that drives the pressing rod 1 to move up and down. It is characterized in that the sewing machine also includes the above-mentioned detection device, which automatically adjusts The method includes the following steps:

[0045] a. The fabric is placed under the intermediate presser 2 and the detection presser 8, the intermediate presser 2 presses against the fabric, the detection presser 8 descends with the intermediate presser 2, and remains in contact with the fabric under the action of the spring 6;

[0046] b. The distance sensor 7 on the fixed plate 3 detects the distance change value of the preset position of the connecting plate 4 and transmits it t...

Embodiment 3

[0050] This embodiment discloses an automatic adjustment method for thread tension on the sewing machine, such as figure 1 and figure 2 As shown, the sewing machine includes a controller, a pressing rod 1, an intermediate presser foot 2 arranged at the lower end of the pressing rod 1, and an electronic thread clamp device. It is characterized in that the sewing machine also includes the above-mentioned detection device, and the automatic adjustment method includes the following steps :

[0051] a. The fabric is placed under the intermediate presser 2 and the detection presser 8, the intermediate presser 2 presses against the fabric, the detection presser 8 descends with the intermediate presser 2, and remains in contact with the fabric under the action of the spring 6;

[0052] b. The distance sensor 7 on the fixed plate 3 detects the distance change value of the preset position of the connecting plate 4 and transmits it to the controller;

[0053] c. The controller control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com