A prebaked anode off-line connection process for aluminum electrolytic cell

A technology of aluminum electrolytic cells and prebaked anodes, which is applied in the field of aluminum electrolysis, can solve the problems of heavy work in the anode assembly workshop, occupation of the turnover guide rod group, environmental pollution, etc., and achieve the goal of avoiding fugitive emissions, simple operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In an electrolytic aluminum plant with an annual production capacity of 500,000 tons in normal production, the technology of "a kind of prebaked anode off-line connection process for aluminum electrolytic cells" of the present invention is used to operate according to the following steps:

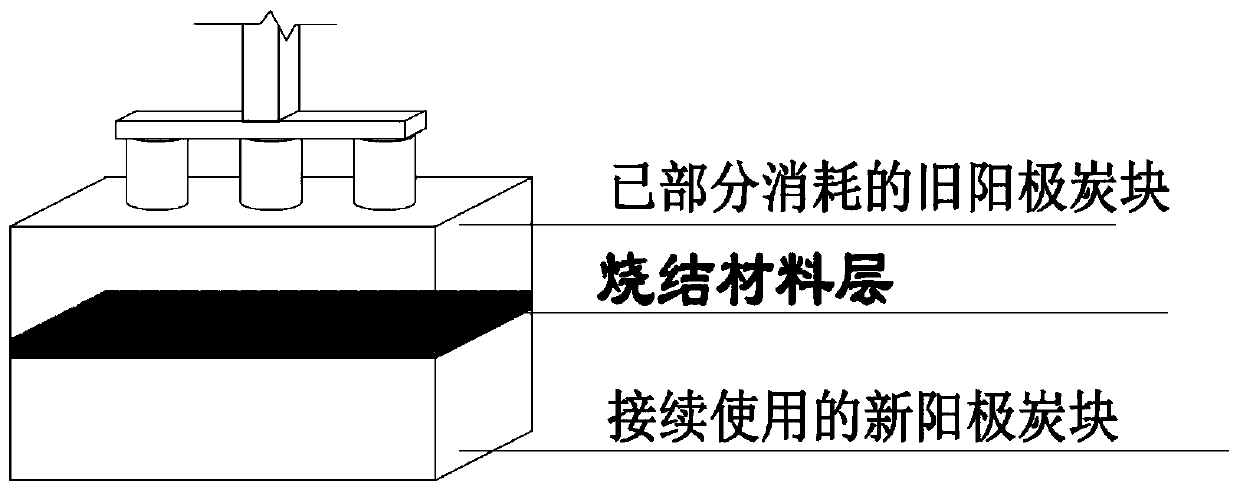

[0049] (1) Prepare the new anode carbon block: put the new anode carbon block with a thickness of 400mm in the sintered smoke exhaust insulation box next to the aluminum electrolytic cell, and coat the sintered and solidified material on the upper surface of the new anode carbon block to form a flat , A sintered solidified material layer covering the complete upper surface, the thickness of the material layer is about 5mm;

[0050] (2) Hang out the old anode carbon block: select an old anode that has been consumed to a remaining thickness of about 300mm from the online anode of the aluminum electrolytic cell, and open the tank cover, scrape the material and crust opening, loosen the ...

Embodiment 2

[0058] In an electrolytic aluminum plant with an annual production capacity of 500,000 tons in normal production, the technology of "a kind of prebaked anode off-line connection process for aluminum electrolytic cells" of the present invention is used to operate according to the following steps:

[0059] (1) Prepare the new anode carbon block: put the new anode carbon block with a thickness of 450mm in the sintered smoke exhaust insulation box next to the aluminum electrolytic cell, and coat the sintered solidified material on the upper surface of the new anode carbon block to form a flat , A sintered solidified material layer covering the complete upper surface, the thickness of the material layer is about 8mm;

[0060] (2) Hang out the old anode carbon block: select an old anode that has been consumed to a remaining thickness of about 250mm from the online anode of the aluminum electrolytic cell, and open the tank cover, remove the material and crust opening, and loosen the a...

Embodiment 3

[0068] In an electrolytic aluminum plant with an annual production capacity of 500,000 tons in normal production, the technology of "a kind of prebaked anode off-line connection process for aluminum electrolytic cells" of the present invention is used to operate according to the following steps:

[0069] (1) Prepare the new anode carbon block: put the new anode carbon block with a thickness of 350mm in the sintered smoke exhaust insulation box next to the aluminum electrolytic cell, and coat the sintered and solidified material on the upper surface of the new anode carbon block to form a flat , A sintered solidified material layer covering the complete upper surface, the thickness of the material layer is about 5mm;

[0070] (2) Hang out the old anode carbon block: select an old anode that has been consumed to a remaining thickness of about 350mm from the online anode of the aluminum electrolytic cell, and open the tank cover, remove the material and crust opening, and loosen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com