Elevator shaft beam for pulling upper telescopic construction lifting machine and installation and use method thereof

A technology for construction elevators and elevator shafts, which is applied to elevators, transportation, and packaging in buildings. It can solve the problems of increasing the amount of wire ropes, wasting manpower and material resources, and unable to guarantee the construction period, so as to reduce labor intensity, save energy, and have novel designs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

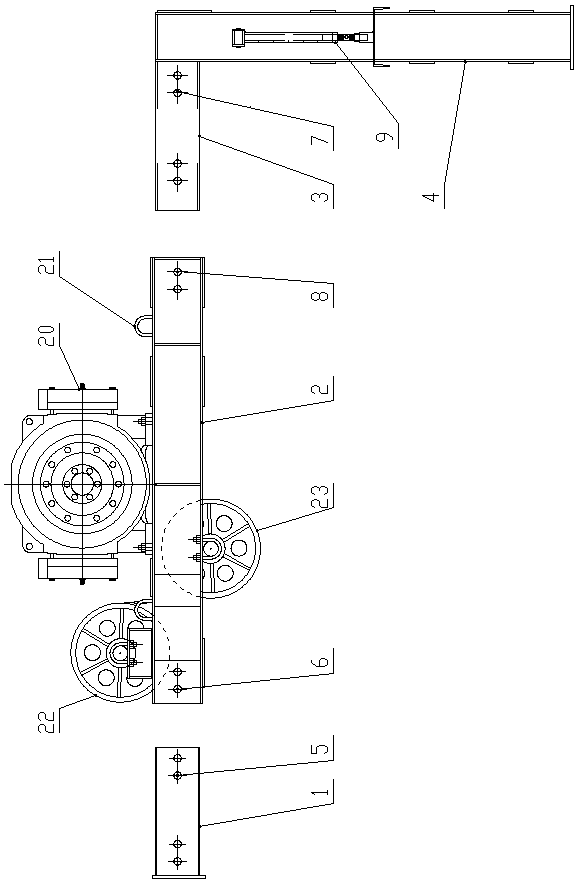

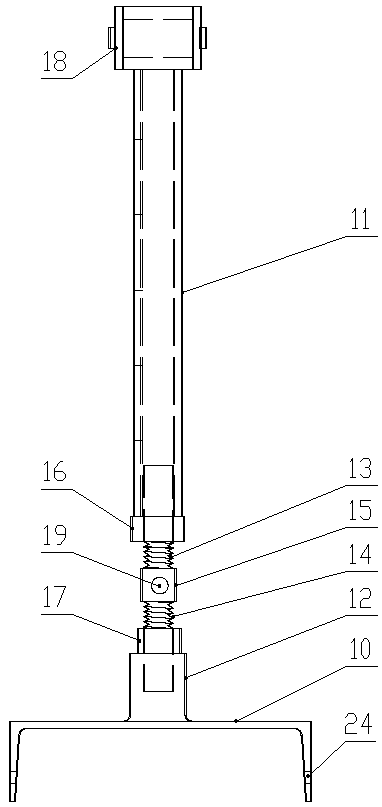

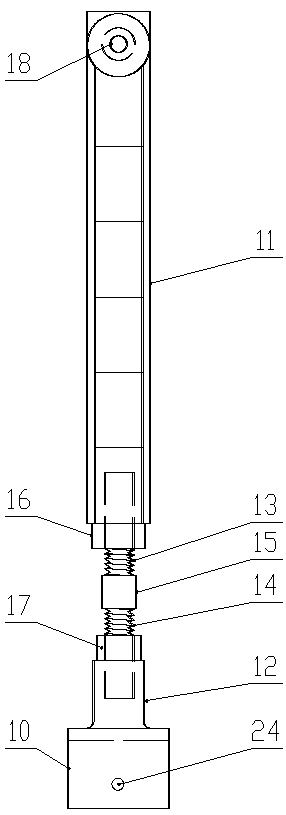

[0038] Such as figure 1 , figure 2 and image 3 As shown, the elevator shaft traction upper telescopic construction hoist sky beam of the present invention comprises a left telescopic short beam 1, a main beam 2, a right telescopic short beam 3 and a pillar beam 4, a left telescopic short beam 1, a main beam 2 and a The right telescopic short beam 3 is arranged along the horizontal direction, and the pillar beam 4 is arranged along the vertical direction. The upper end of the pillar beam 4 is fixedly connected with the right end of the right telescopic short beam 3 to form an L-shaped structure; Folding positioning bar 9;

[0039] The main beam 2 is welded by two 20# channel steels with opposite openings, and the left telescopic short beam 1, the right telescopic short beam 3 and the pillar beam 4 are all welded by two 18# channel steels with opposite openings;

[0040] The left telescopic short beam 1 is inserted inside the left end of the main beam 2. The left telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com