Medical robot for myopic surgery

A medical robot and myopia surgery technology, applied in the medical field, can solve problems such as single control direction, unfavorable assembly structure, and material fatigue, and achieve the effects of low production cost, convenient operation, and precise work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

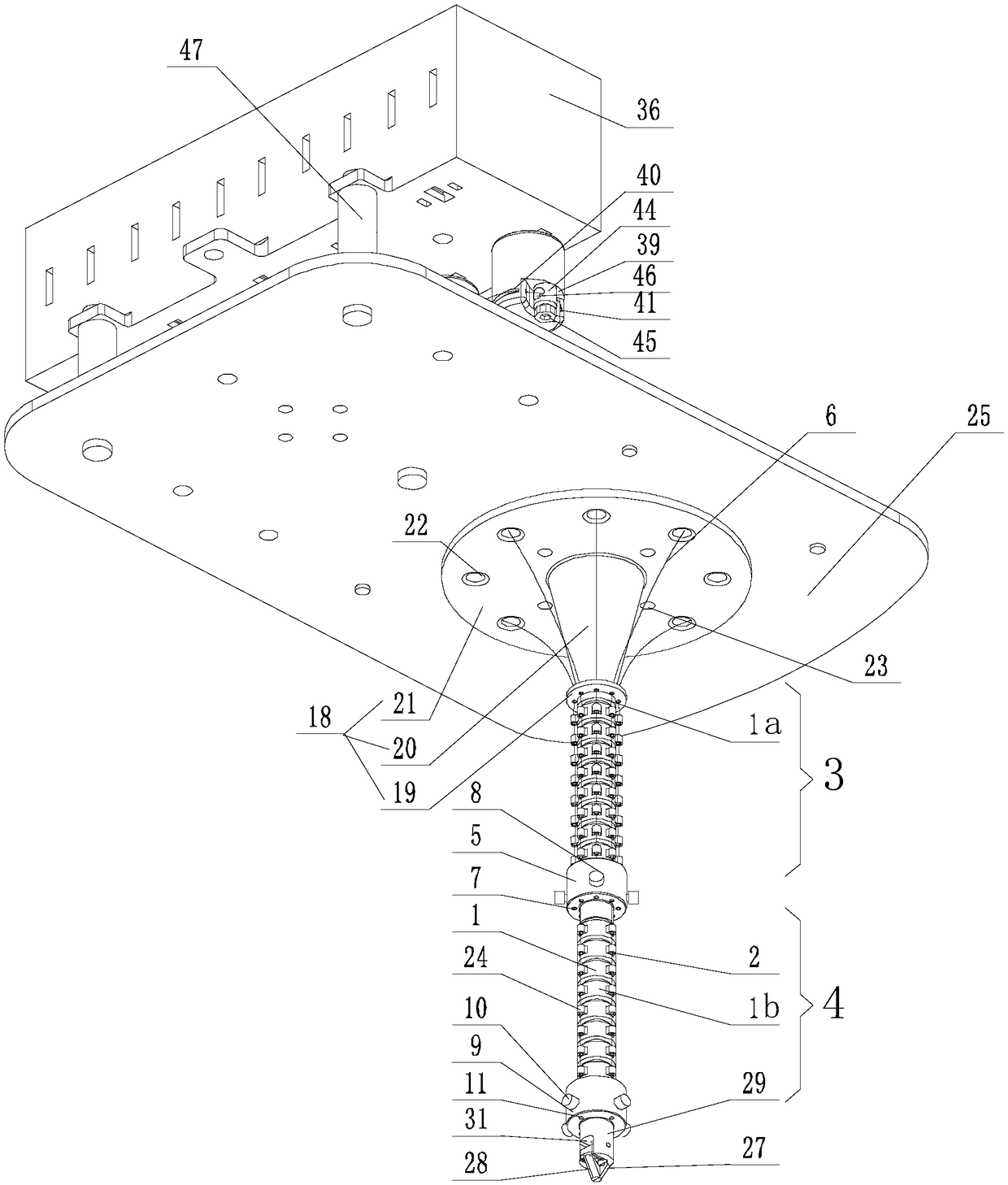

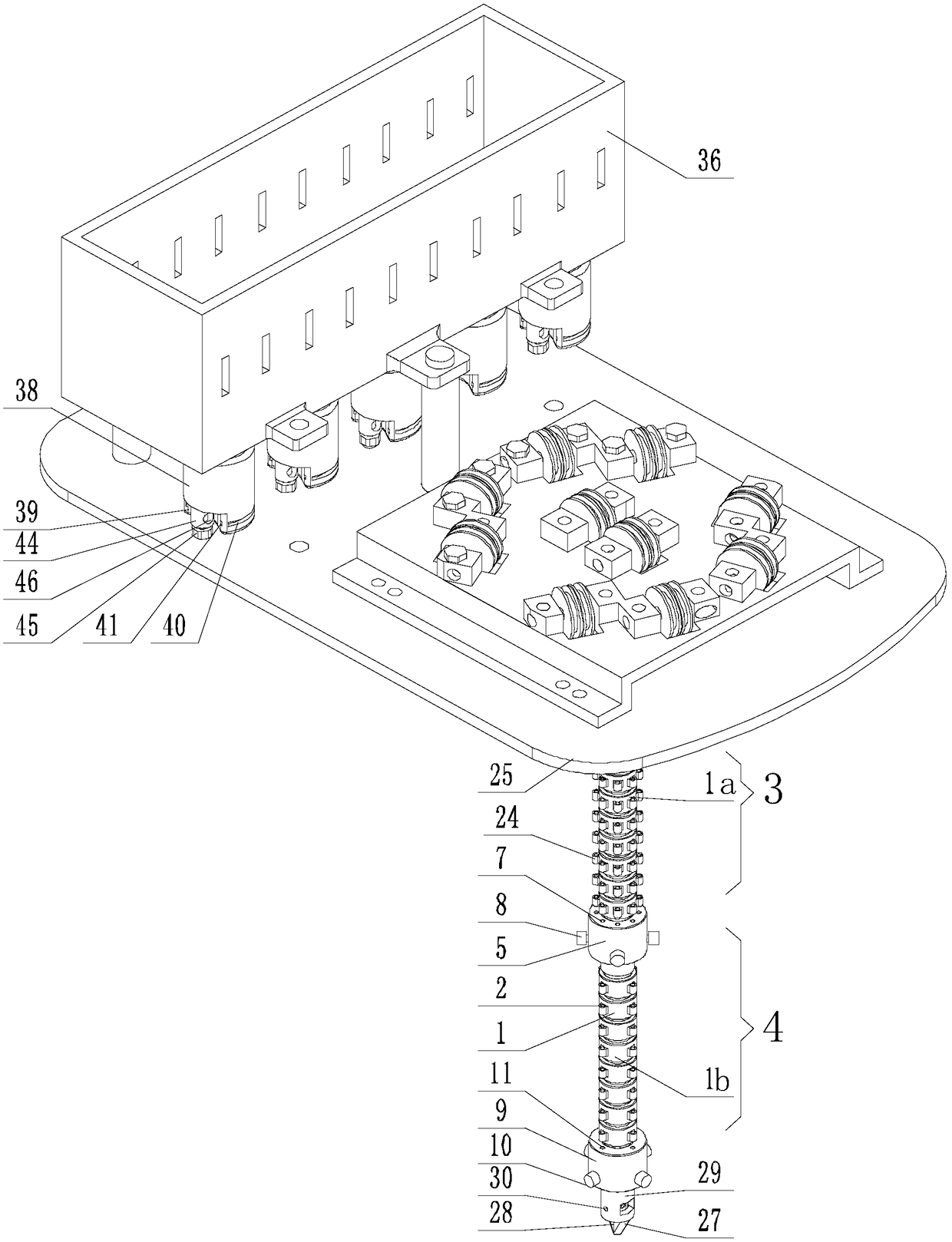

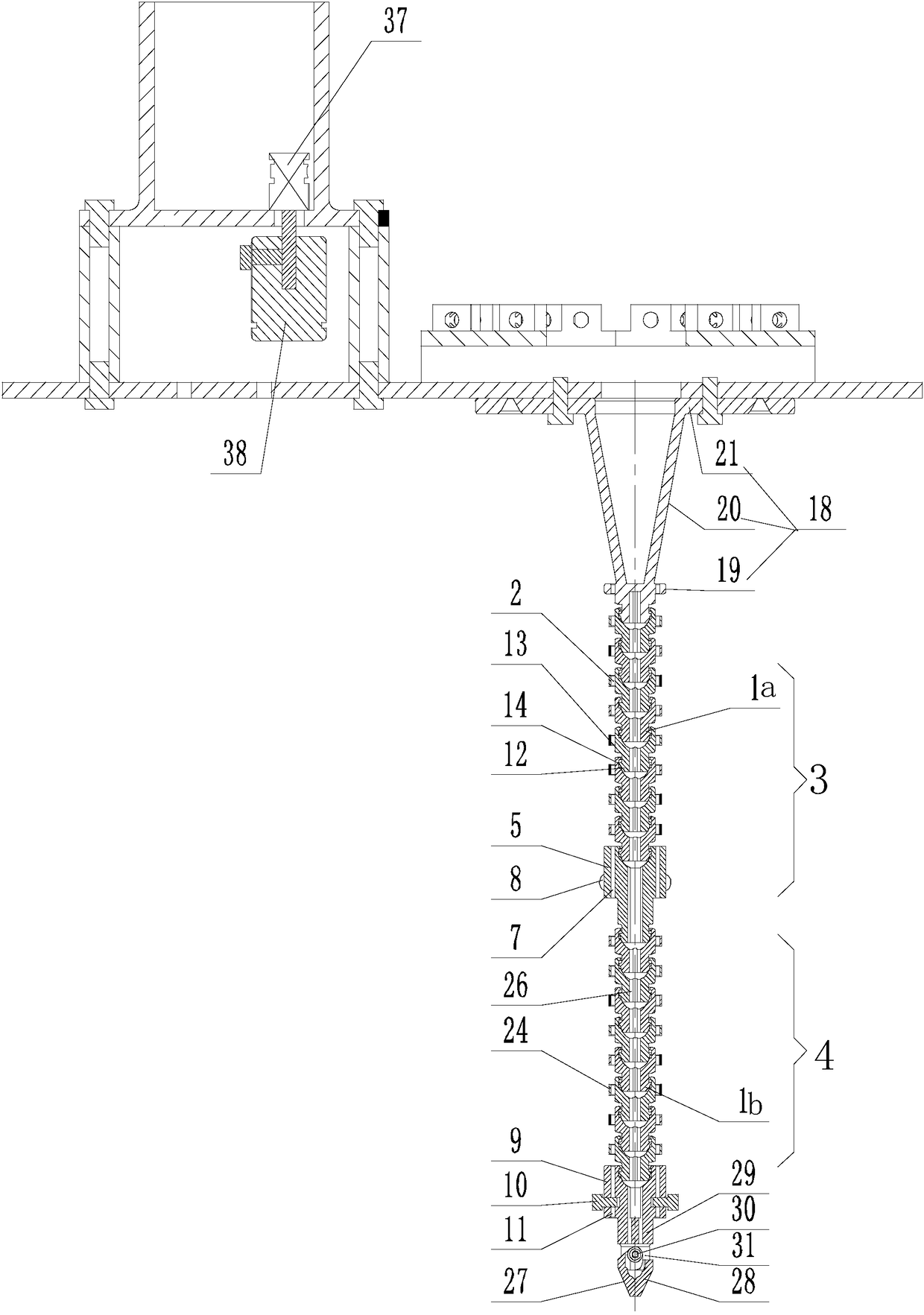

[0063] Such as Figure 1-Figure 10 As shown, the present invention is used for the medical robot of myopia operation, comprises drive line 6 and the coiling device that connects in sequence, drive device, support plate 25, joint section and clamping assembly, and described joint section comprises several successive ball joints The joint unit 1 is provided with a main through hole 26 and an even number of wire holes 2. The axes of the wire holes 2 are all parallel to the axis of the main through hole 26 and along the center of the axis of the main through hole 26. Symmetrical, and the wire holes 2 of two adjacent joint units 1 correspond one-to-one;

[0064] The joint unit 1 located at the head end of the joint segment is fixed on the support plate 25, the joint unit 1 located at the end of the joint segment is connected to the clamping assembly, the drive device is fixed on the support plate 25, and the output shaft of the motor in the drive device is connected to the line de...

Embodiment 2

[0074] This embodiment is an illustration of the manner in which the driving wire 6 is fixed at the tail end of the joint segment.

[0075] Such as Figure 1-Figure 3 as well as Figure 13-Figure 14 As shown, a wire fixing seat 9 and several limit bolts 10 are arranged at the tail end of the joint segment, and the bottom of the wire fixing seat 9 is spherically hinged with the joint unit 1 at the tail end of the joint segment. There are several through holes II11, the limit bolts 10 are threadedly connected with the wire fixing seat 9, and the rotation of the limit bolts 10 can make the ends of the rods respectively inserted into one of the through holes II11, and the joint drive wires are respectively inserted into One through hole II11, and each is pressed on the hole wall of the through hole II11 by a limit bolt.

Embodiment 3

[0077] This embodiment is to illustrate the actual use of the joint segment.

[0078] Such as Figure 1-Figure 7 As shown, there are two joint segments, which are divided into the first closing stage 3 and the second joint segment 4 located on the side away from the driving end in the first closing stage. The joint unit in the first closing stage 3 is the first joint unit 1a, the joint unit in the second joint segment 4 is the second joint unit 1b, and the number of wire holes 2 on the first joint unit 1a is eight, which is twice the number of wire holes 2 on the second joint unit 1b , a wire solid block 5 is arranged between the first closing stage 3 and the second joint segment 4, and one end of the wire solid block 5 is ball-hinged with the tail end of the first closing stage 3, and the other end of the wire solid block 5 is connected to the second joint segment. The head end of the joint segment 4 is hinged, and the number of joint driving wires is the same as the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com