Structure design method of rotor wing paddle

A technology of structural design and rotor blades, which is applied in the field of rotor blades, can solve problems such as blade aerodynamic performance, unequal installation angles, high manufacturing process quality requirements, and complex rotor manufacturing processes, so as to shorten the design cycle and reduce design costs. cost, the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

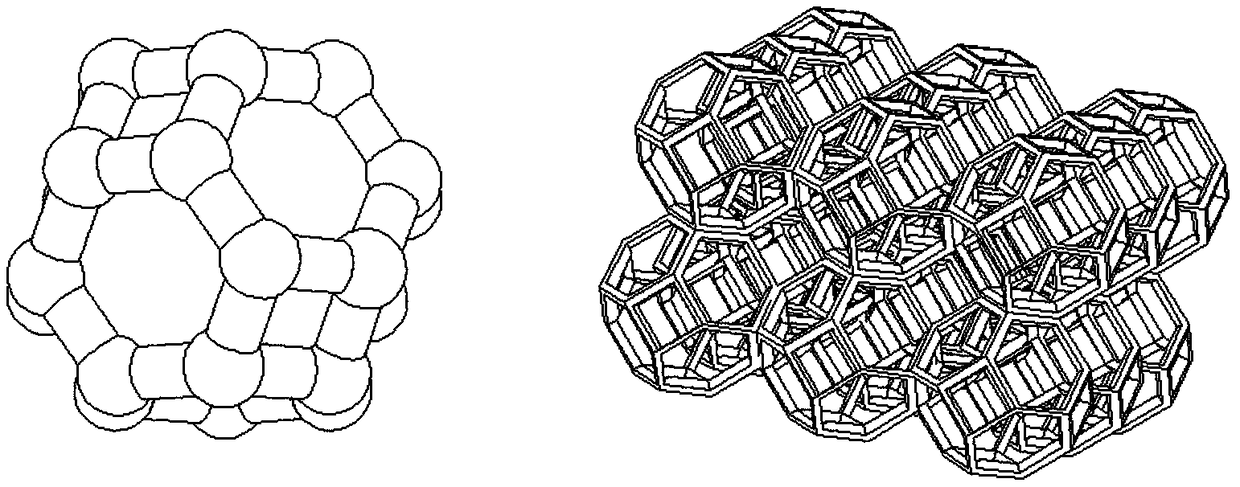

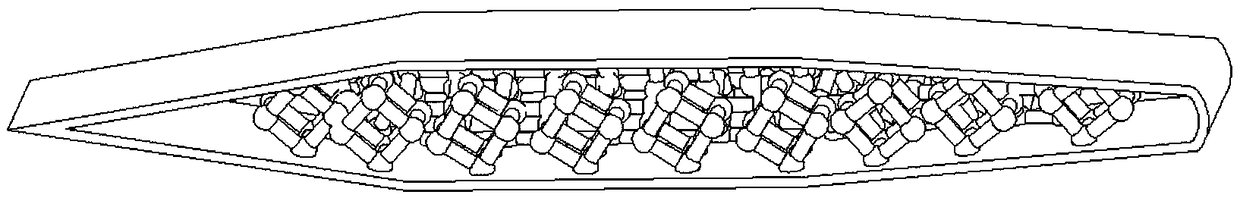

[0023] refer to Figure 1-2 , a rotor blade structural design method, at first, select suitable lattice unit and engineering metal material, and carry out lattice unit mechanical analysis model, described lattice unit has multiple optional lattice units such as 14-hedron unit , optional materials include aluminum alloy, titanium alloy or stainless steel and other optional engineering materials;

[0024] Then, establish a unit mechanical analysis model for the 14-hedron lattice unit selected in the previous step, in order to prepare for the overall structural optimization design of the subsequent blade;

[0025] Next, it is necessary to design the internal lattice st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com