Product molding method based on FDM technology

A molding method and product technology, applied in the field of 3D printing, can solve problems such as low printing efficiency, achieve the effects of improving utilization rate, avoiding wire drawing, and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments

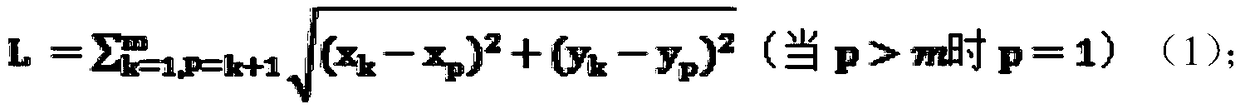

[0037] Such as figure 1 A product molding method based on FDM technology shown includes the following printing steps:

[0038] (1) According to the input two-dimensional graphics data of the bottom surface, print the contour of the first layer of graphics on the bottom surface, and print at least one circle along the contour;

[0039] (2) After printing along the contour, the end point of the last printing is the starting point of the internal structure of the bottom surface of the printing, and the internal structure is printed in a reciprocating motion in a line manner;

[0040] (3) After the first layer of graphics is printed, the print head moves to the peripheral contour of the next layer of graphics according to the coordinates set by the two-dimensional graphics data, and returns to step (1) until the printing of all the bottom layers of graphics is completed Perform the nex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com