Irregular working surface wheel poking machine

A technology for working surfaces and pullers, which is applied in the manufacture of tools, hand-held tools, etc., and can solve problems such as danger, time-consuming and labor-intensive, and wheel shaft corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

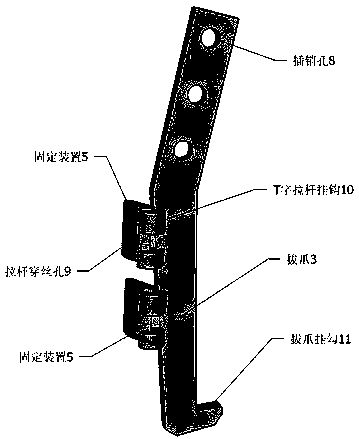

[0019] as attached figure 1 Shown: a puller 1 for irregular working surfaces is composed of: mounting bracket 1, top screw 2, pulling claw 3, latch screw 4; fixing device 5, pull rod bolt 6, pull rod screw cap 7, adjustment hole 8, pull rod wear The thread hole 9, the T-shaped pull rod hook 10, and the claw hook 11 form together.

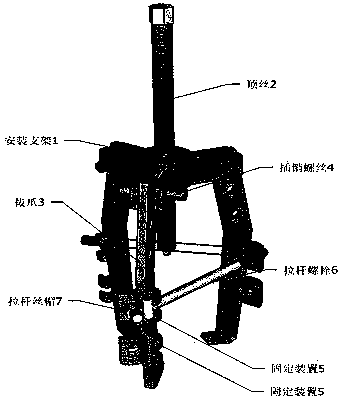

[0020] as attached figure 2 As shown: the claw 3 of a puller 1 on an irregular working face has a fixed locking device, which is composed of a fixing device 5 on the puller 3 and a tie rod bolt 6. On each claw, 1 to 3 fixing devices 5 can be arranged, which are used in conjunction with the adjustment holes on the pulling melon to achieve the function of coping with more complex working surfaces.

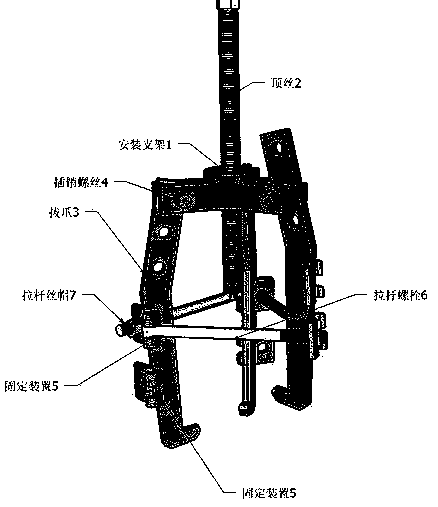

[0021] as attached image 3 Shown: a puller for irregular working surface 1 In order to deal with more complicated working contact surfaces and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com