Modeling method of robot forearm assembly system based on timed petri net

An assembly system and modeling method technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to express system time factors, poor reusability and maintainability, difficulty in model establishment and improvement, etc., to achieve Reusable, maintainable, focused effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

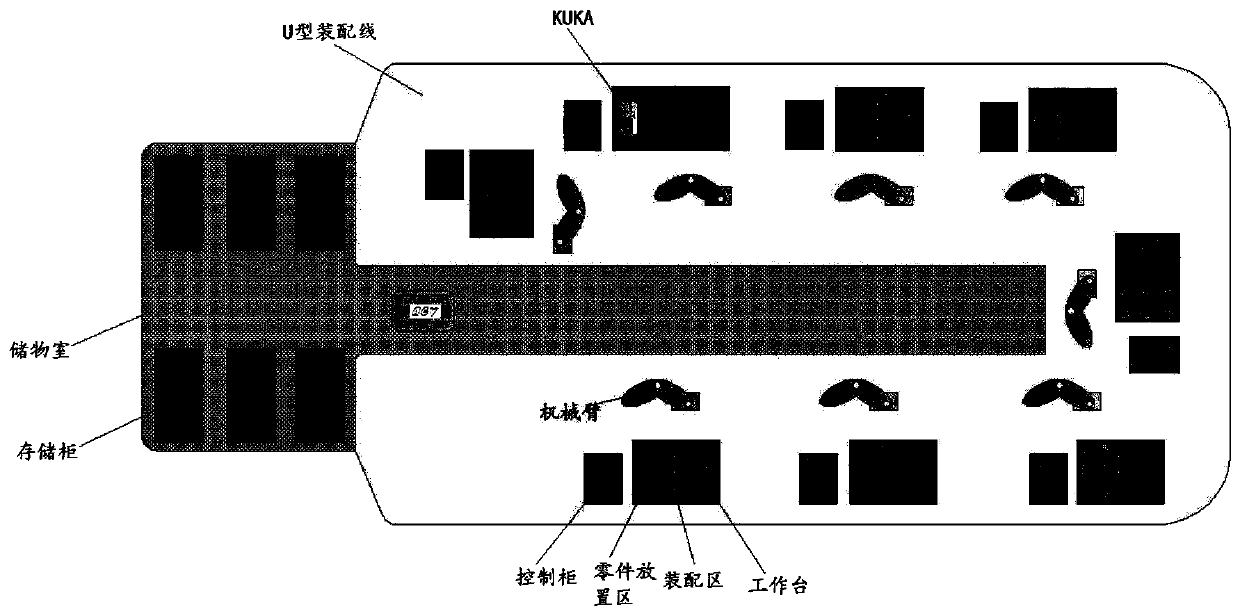

[0024] A method for modeling a robotic forearm assembly system based on timed Petri nets, comprising the following steps:

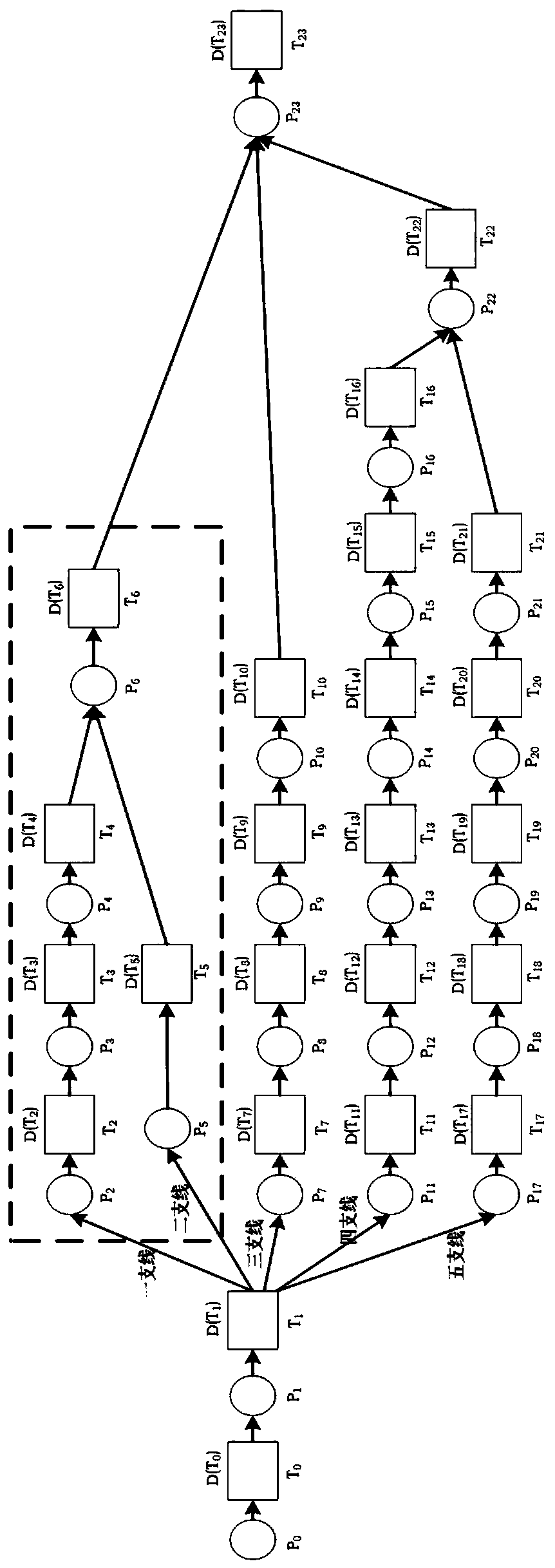

[0025] The first step is to establish a process-based timed Petri net model with a top-down idea from a global perspective;

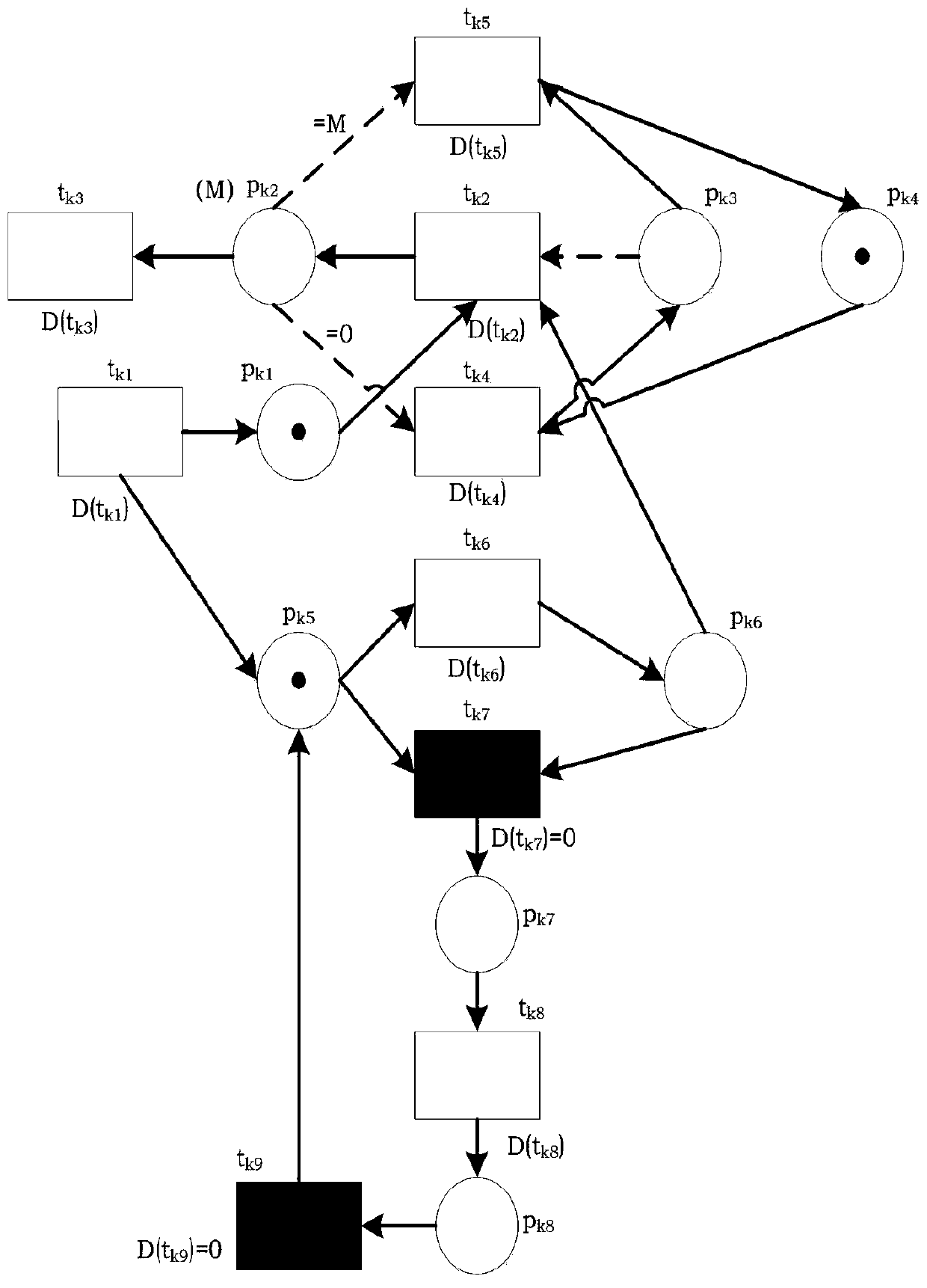

[0026] In the second step, starting from a local point of view, a timed Petri net model based on any process is established with a bottom-up idea;

[0027] The third step combines and refines the models built in the first two steps.

[0028] In the first step, from a global perspective, a process-based timed Petri net model is established with a top-down idea:

[0029] Firstly, the whole robot forearm assembly system is designed, and the detailed activity process within each process is temporarily ignored, and a process-based timed Petri net model is established by using the top-down idea. Then design the detailed activities of the specific process in the assembly line, and use the bottom-up idea to establish a timed Petri net mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com