Injection molding device

An injection molding and equipment technology, applied in metal processing equipment, drilling/drilling equipment, clamping, etc., can solve the problems of inability to achieve equidistant drilling operations, difficulty in meeting existing needs, and high use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

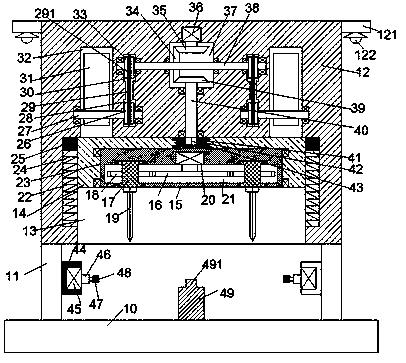

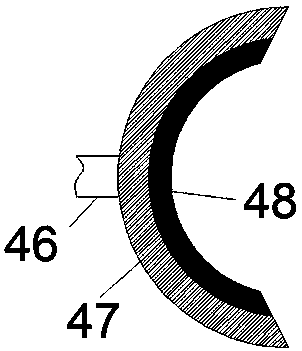

[0015] Such as Figure 1-2 As shown, an injection molding equipment of the present invention includes a base 10, a support column 11 symmetrically arranged on the top end surface of the base 10, and a mounting frame 12 arranged above the support column 11. The mounting frame 12 The bottom end face is provided with a sliding chamber 13 with an opening downward, and a turret 15 is slidably installed in the sliding chamber 13, and a first rotating chamber 23 is arranged in the bottom end face of the turret 15, and the first rotating chamber 23 A turret 15 is rotatably installed through a rotatable bearing, and a second rotating cavity 21 extending left and right is provided in the turret 15, and the inner top wall of the second rotating cavity 21 is fixedly provided with a first motor 20, and the first motor 20 is fixed on the inner top wall of the second rotating cavity 21. The bottom of a motor 20 is power-connected with the first rotating gear 16 located in the second rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com