Hot rolling flattening unit laser plate shape monitoring method and system

A leveling and laser technology, which is applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems that the quality inspection method cannot meet the requirements, and the number of objections to the quality of thin-gauge plates increases, so as to reduce the quality of the plate shape Effects of objection, improvement of production efficiency, and expansion of display level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods not indicating specific conditions in the following examples, follow conventional methods and conditions. The raw materials used in the following examples are all commercially available.

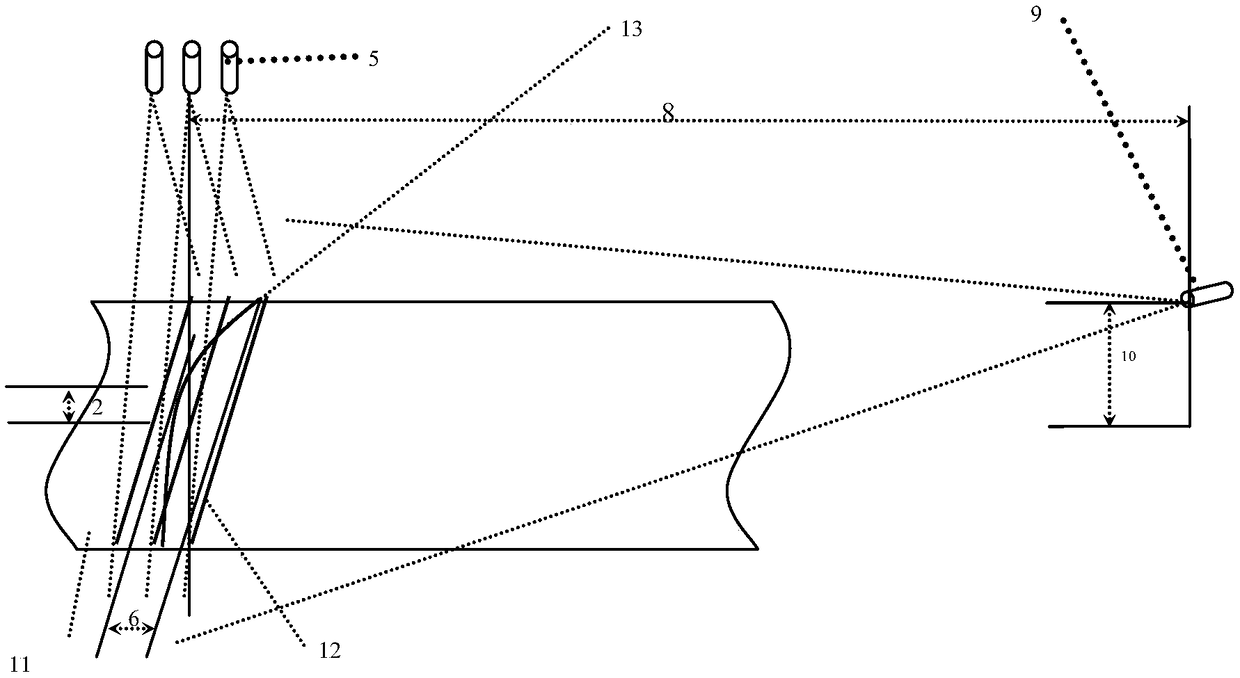

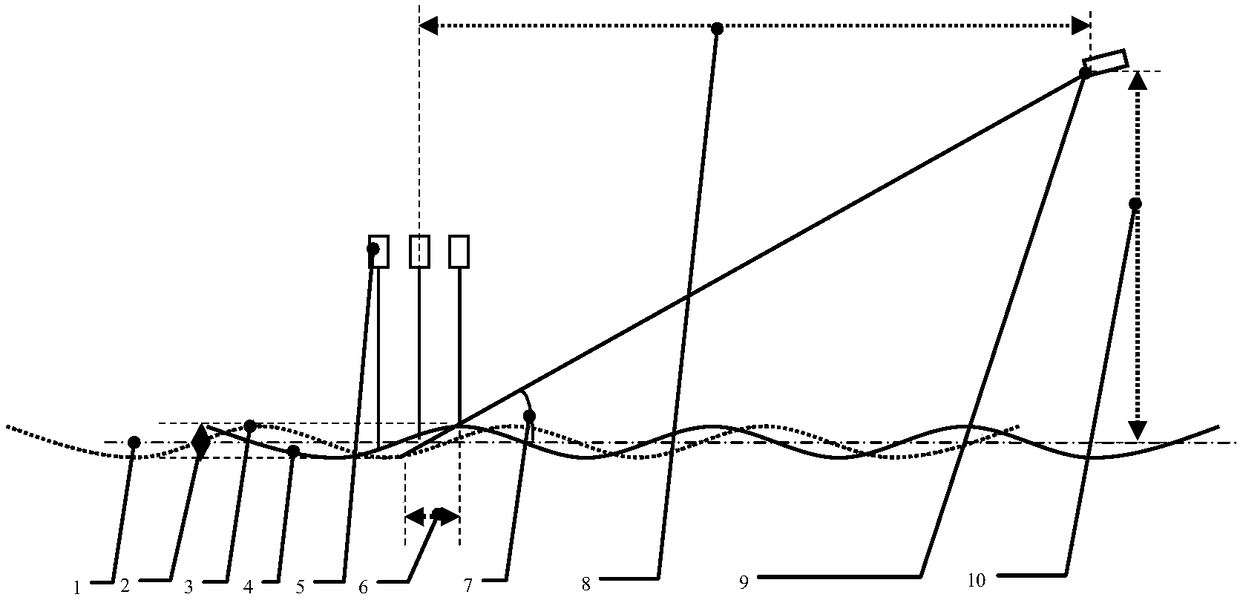

[0070] The present invention is installed and used in the 2250 tempering unit of Taiyuan Iron and Steel Co., Ltd., and the installation position is at the post-shearing inspection table at the exit of the temper mill:

[0071] (1) Installation and debugging of laser transmitter

[0072] 1. Determine the appropriate installation position according to the actual situation on site, and make the installation bracket.

[0073] 2. Install a suitable power supply according to the equipment requirements.

[0074] 3. Install the first laser emitter 5 so that it emits laser standard lines 12 perpendicular to the plane 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com