Vibrating sieve capable of adjusting size of sieve holes

A technology of sieve hole size and vibrating screen, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of affecting work efficiency, the sieve aperture cannot be adjusted, etc., to improve work efficiency, avoid frequent replacement of sieve plates, Easy to assemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

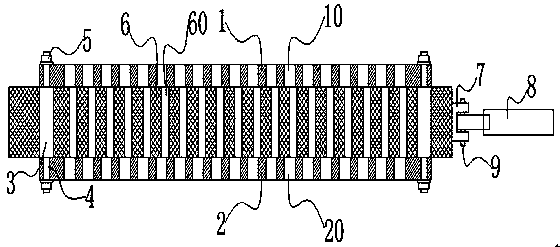

[0009] Such as figure 1 As shown, the present invention discloses a vibrating screen with adjustable sieve hole size, comprising: vibrating screen one 1 and vibrating screen two 2, the vibrating screen one 1 and vibrating screen two 2 are arranged at an upper and lower distance, and the The vibrating screen one 1 and the vibrating screen two 2 are supported and connected by a plurality of connecting columns 3, and the vibrating screen one 1, vibrating screen two 2, and multiple connecting columns 3 are connected by double-ended screws 4. Tightly connected, and lock nuts 5 that are threaded and installed at both ends of the double-ended screw rod 4 are locked and connected.

[0010] The vibrating screen one 1 and the vibrating screen two 2 are respectively provided with a plurality of screen holes one 10 and two screen holes 20 corresponding up and down, and the distance between the vibrating screen one 1 and the two vibrating screens An interlayer sieve plate 6 is provided, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com