New energy automobile battery recycling, detection and reutilization device

A new energy vehicle and battery recycling technology, which is applied in the direction of mechanical solid deformation measurement and sorting, can solve the problems of improper operation, damage, fire and explosion of batteries, and achieve the effect of reducing corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

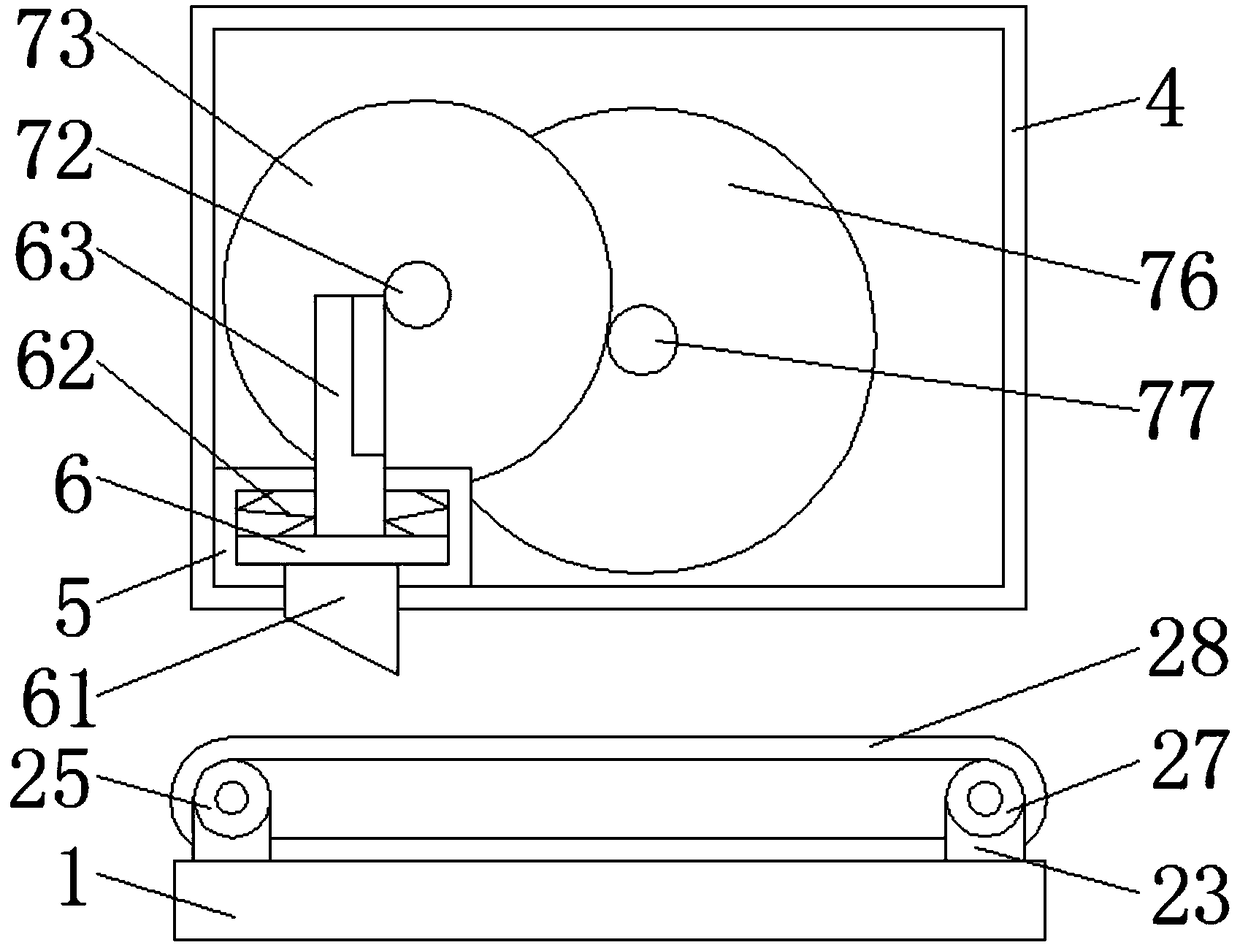

[0024] The following is attached Figure 1-4 The present invention is described in further detail.

[0025] A new energy vehicle battery recycling detection reuse device, such as Figure 1-4As shown, it includes a base 1, the upper surface of the base 1 is provided with a transmission device, and the transmission device includes a motor base 2, the upper surface of the motor base 2 is fixedly connected with a rotating motor 21, and the output shaft of the rotating motor 21 is fixed by a coupling Connected with a rotating rod 22, the upper surface of the base 1 is fixedly connected with a bearing seat 23, and the inner wall of the bearing seat 23 is fixedly connected with a fixed bearing 24, and the inner walls of the two fixed bearings 24 are fixedly connected with the surface of the rotating rod 22, and the rotating rod 22 The surface of the fixed bearing 25 is fixedly connected with the driving drum 25, and the inner rings of the other two fixed bearings 24 are fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com