Fully-prefabricated pile top crown beams capable of being recycled, and construction method thereof

A technology of prefabricated piles and crown beams, applied in excavation, foundation structure engineering, construction, etc., can solve the problems of inability to recycle, fail to reduce the cost of crown beams, and occupy large human resources, so as to ensure the firmness and stability of the connection Sex, reduce construction cost, reduce the effect of construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

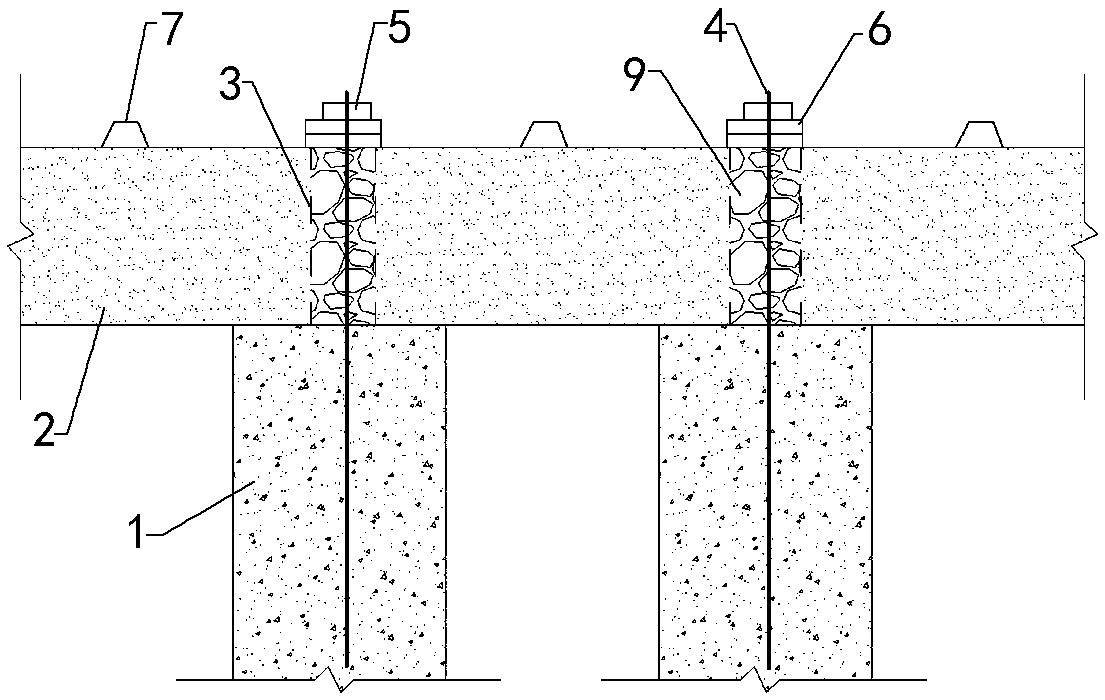

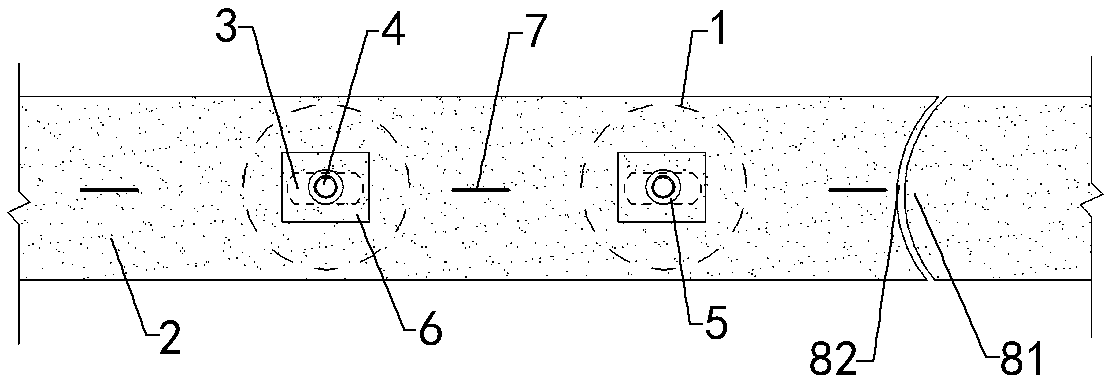

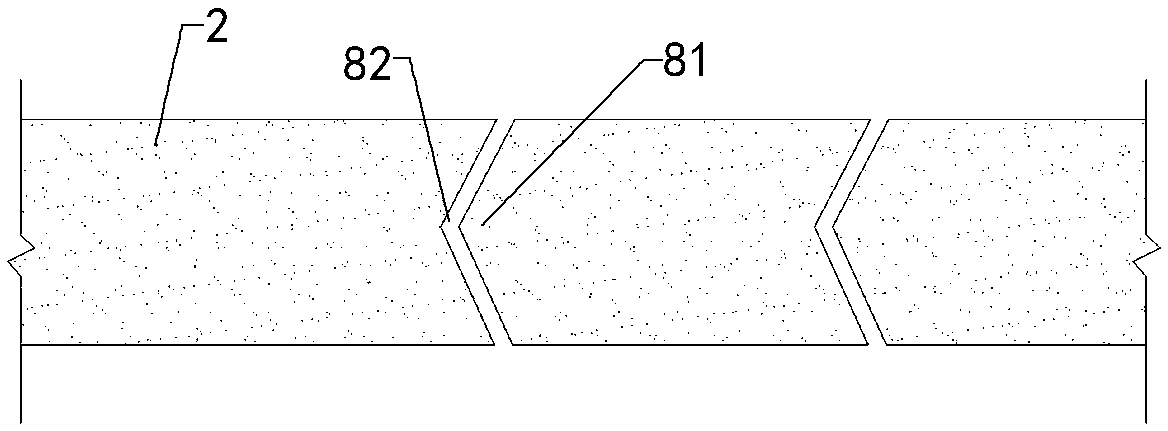

[0038] Such as Figure 1 to Figure 4 As shown, the recyclable fully prefabricated pile top crown beam of the present invention is arranged on the top of support piles 1, and spliced sequentially to connect adjacent support piles 1.

[0039] The crown beam 2 is a rectangular parallelepiped reinforced concrete structure. An anchor hole 3 is vertically arranged on the crown beam 2. The anchor hole 3 corresponds to the connecting anchor cable 4 pre-buried on the top of the support pile 1. The anchor hole 3 is an oblong through hole. Holes, the length of which is not less than 150mm, the connecting anchor cables 4 are steel strands, the length and number of embedded concrete are mainly determined according to the anchoring force provided by the design, and 1-2 bundles of connecting anchor cables can be set in each supporting pile 1 4. The connecting anchor cable 4 passes through the anchor hole 3 vertically, and is locked and fixed by the anchor 5. A steel backing plate 6 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com