A kind of release paper with stearate as release agent

A stearate, release paper technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of high coating weight, low peeling force, unfavorable PU resin film formation, etc., and achieve low coating weight. , The effect of stable peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

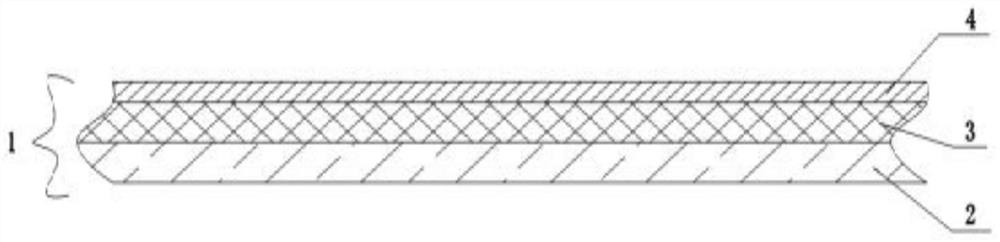

Image

Examples

Embodiment 1

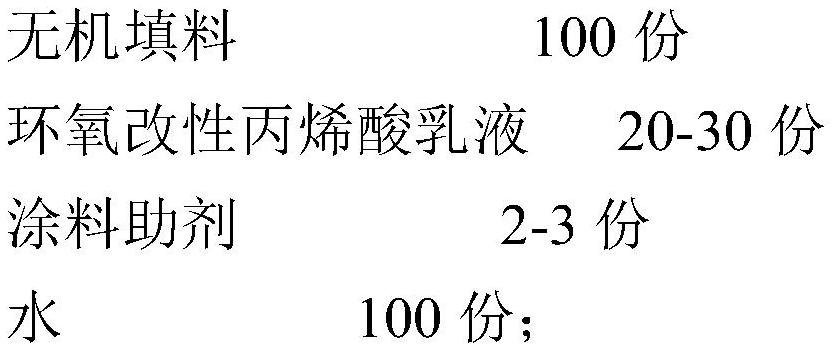

[0048] (1) The raw material composition of the impermeable layer

[0049]

[0050] 100 parts by weight of deionized water, add 1 part by weight of water-based dispersant (Bocheng Chemical SP-5040), add 100 parts by weight of light calcium carbonate (2000 mesh, Lingshou County Baifeng Mineral Products Processing Factory) under stirring conditions, Stir and disperse at high speed for 1 hour at a speed of 3000r / min, then add epoxy-modified acrylic emulsion (BLJ-6050A, Changzhou Aobang Chemical Co., Ltd. After stirring evenly, an anti-penetration layer coating solution was prepared, with a solid content of 49%, a pH of 9, and a viscosity of 560 cps.

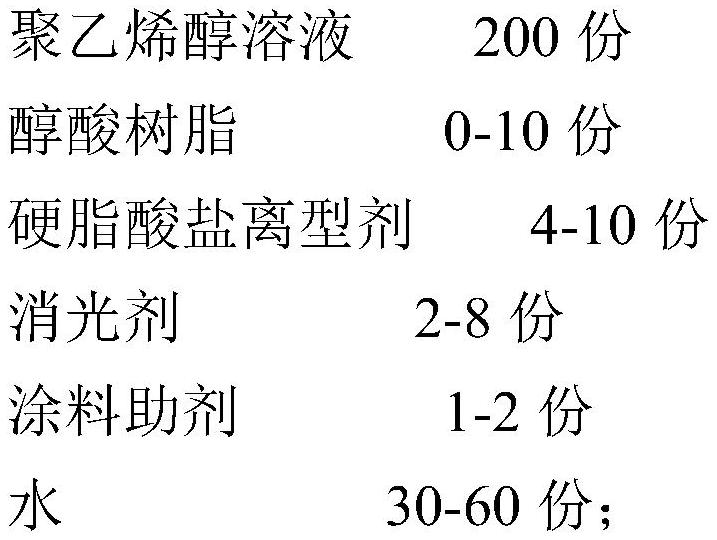

[0051] (2) Raw material composition of release layer

[0052]

[0053] Add 4 parts by weight of fumed silica (2500 mesh, Wacker HDK-N20) into 30 parts by weight of deionized water, disperse in a high-speed mixer for 1 hour, and rotate at a speed of 3000r / min, then add polyvinyl alcohol solution, alcohol Acid resin (Shandong Jia...

Embodiment 2

[0056] (1) The raw material composition and process of the anti-seepage layer are the same as in Example 1

[0057] (2) Raw material composition of release layer

[0058]

[0059] Add 8 parts by weight of fumed silica (2500 mesh, Wacker HDK-N20) into 60 parts by weight of deionized water, disperse in a high-speed mixer for 1 hour, and rotate at a speed of 3000r / min, then add polyvinyl alcohol solution, alcohol Acid resin (Shandong Jiaying Chemical HKP-3180), chromium stearate (Zhengzhou Hanshuo Chemical Raw Materials Co., Ltd.), silicone leveling agent (Bocheng Chemical SP-931), continue to stir evenly to make a release layer coating The cloth liquid has a solid content of 15%, a pH of 3.1, and a viscosity of 380cps.

[0060] The quantitative is 140g / m 2 The anti-penetration layer coating liquid is coated on the paper base by doctor blade coating process, the coating speed is 40m / min, the oven drying temperature is 140°C, and the coating amount of the anti-penetration lay...

Embodiment 3

[0062] (1) The raw material composition and process of the anti-seepage layer are the same as in Example 1

[0063] (2) Raw material composition of release layer

[0064]

[0065] Add 3 parts by weight of aluminum hydroxide (2500 mesh, Shanghai Liangjiang Titanium White Chemical Products Co., Ltd.) into 30 parts by weight of deionized water, disperse in a high-speed mixer for 1 hour, and rotate at a speed of 3000r / min, then add polyvinyl alcohol in sequence according to the above parts by weight solution, zinc stearate emulsion (Dongguan Miaoke Industrial Co., Ltd.), polyether modified silicone wetting agent (Bocheng Chemical SP-994), and continue to stir evenly to make a release layer coating solution. The solid content It is 11%, the pH is 3.2, and the viscosity is 310cps.

[0066] The quantitative is 140g / m 2 The anti-penetration layer coating liquid is coated on the paper base by doctor blade coating process, the coating speed is 60m / min, and the oven drying temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com