Container and cover double-plate alternate receiving conveying device

The technology of conveying device and container is applied in the field of alternate material receiving and conveying device of container and lid, which can solve the problems of height limitation of material receiving device, collision with cup making machine, low working efficiency, etc. Smooth and efficient effect with simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

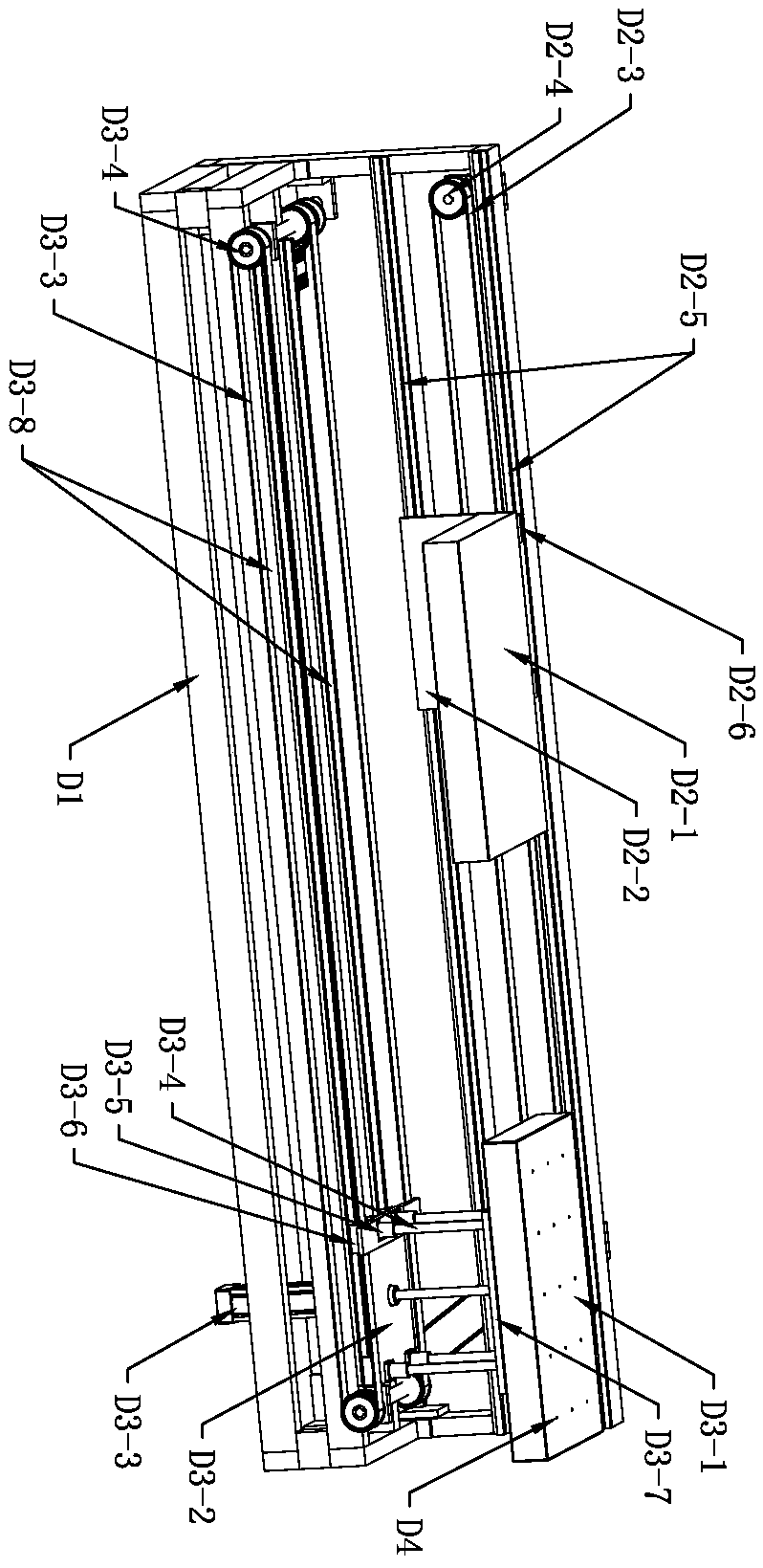

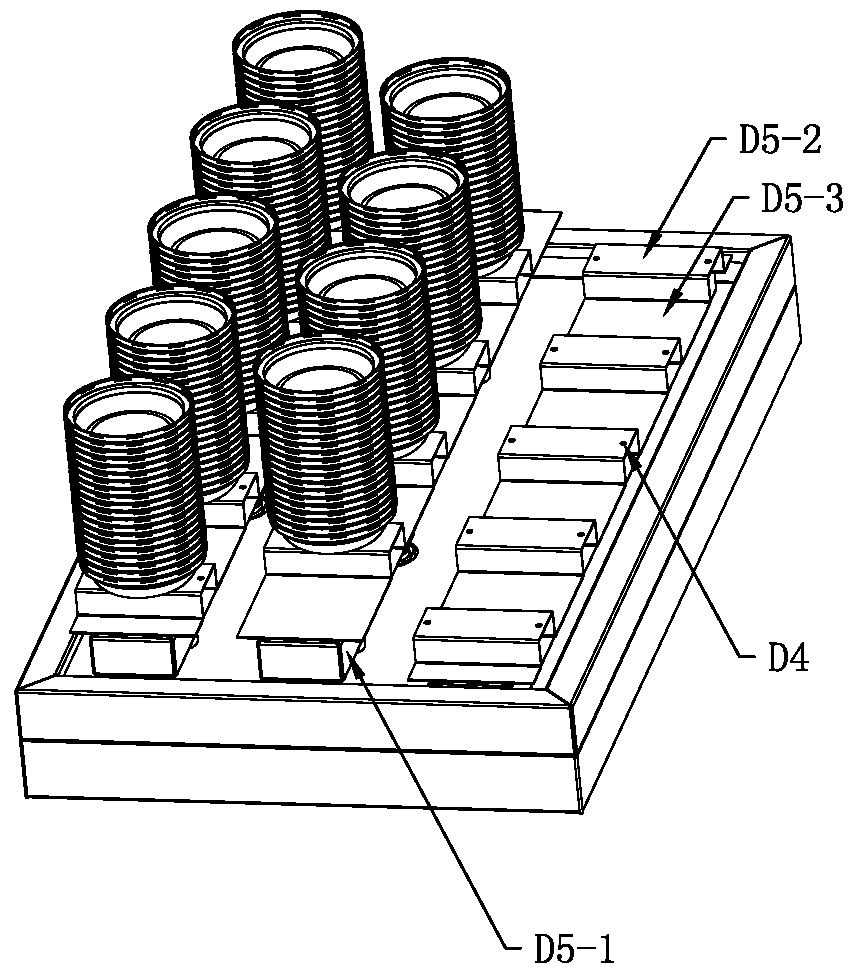

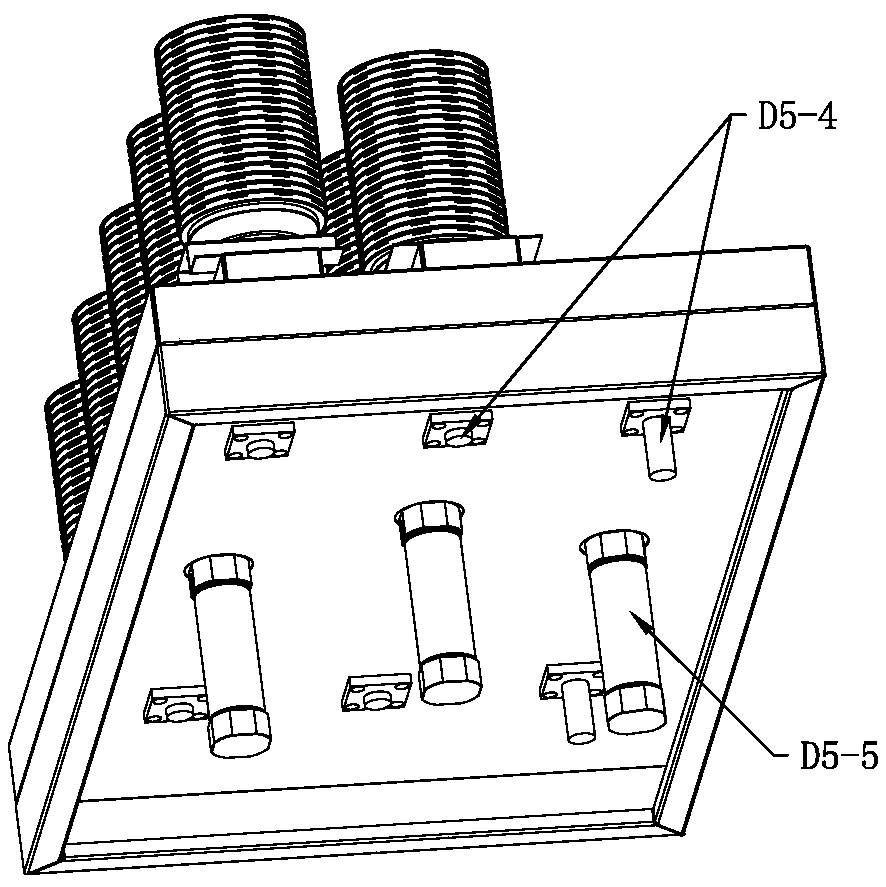

[0046] see Figures 1 to 5, the container and cover double-disc alternate receiving and conveying device D includes a support frame D1, an upper receiving tray D2-1, an upper translation drive mechanism, a lifting tray D3-1, a lower translation drive mechanism, and a tray lifting drive mechanism , the support frame D1 is composed of a bottom frame D1-2 and a side frame D1-1, the upper receiving tray D2-1 is installed on the side wall of the side frame D1-1, and the upper translation drive mechanism is installed on the side frame D1-1, The lower translation driving mechanism is installed on the chassis D1-2, and the upper translation driving mechanism is located above the lower translation driving mechanism. Chain and drive wheel D2-4 form. There are two parallel guide rails D2-5 on the top and bottom of the transmission belt D2-3 or the transmission chain of the upper translation drive mechanism, and the slider D2-6 of the guide rail D2-5 passes through the supporting side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com