A loc mechanism for a vehicle body frame of a through-road

A through-channel and vehicle body technology, applied in the field of the through-channel vehicle body frame locking mechanism, can solve problems such as inconvenient operation and long dismantling time, and achieve the effects of convenient operation, saving production process costs, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

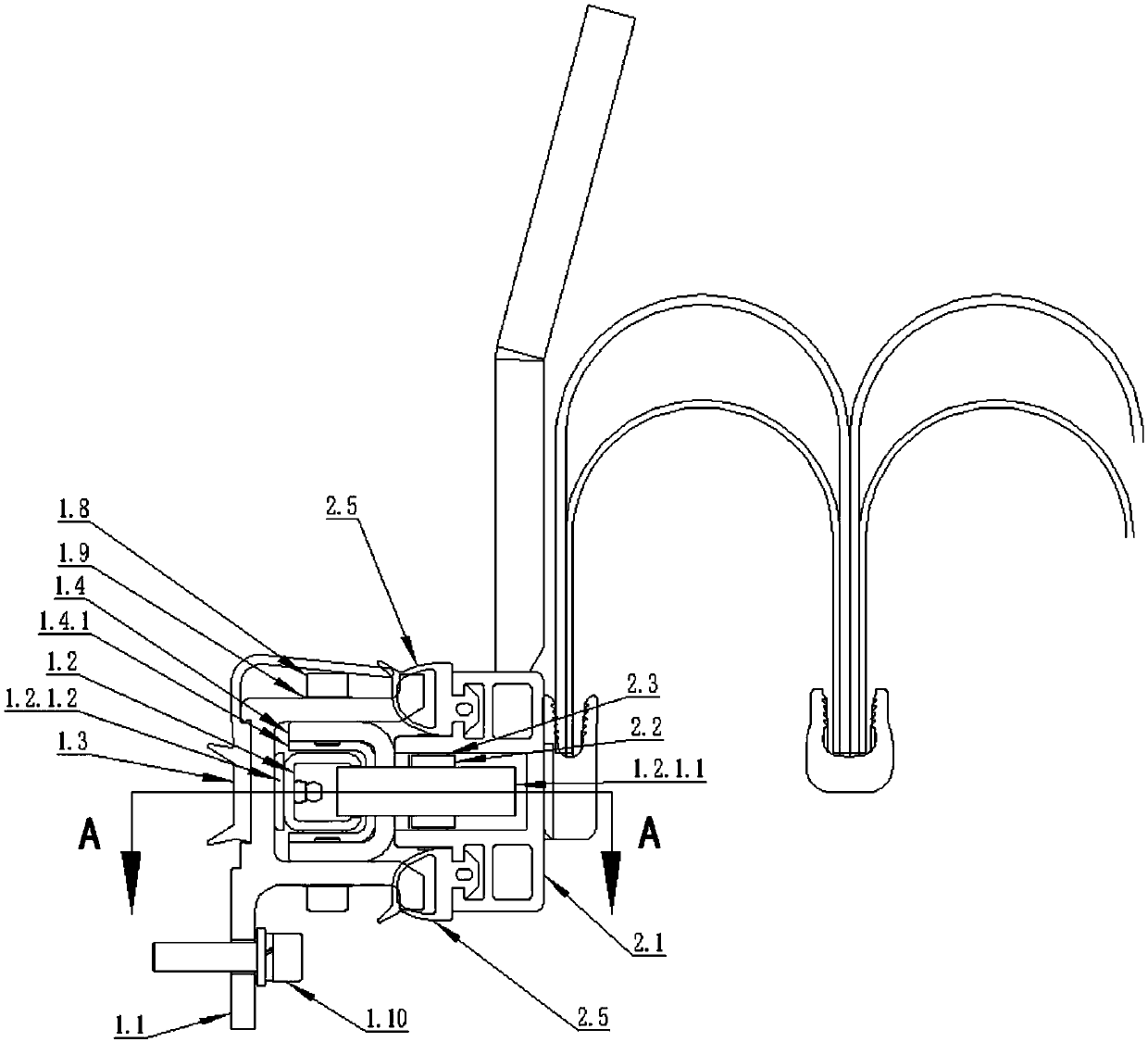

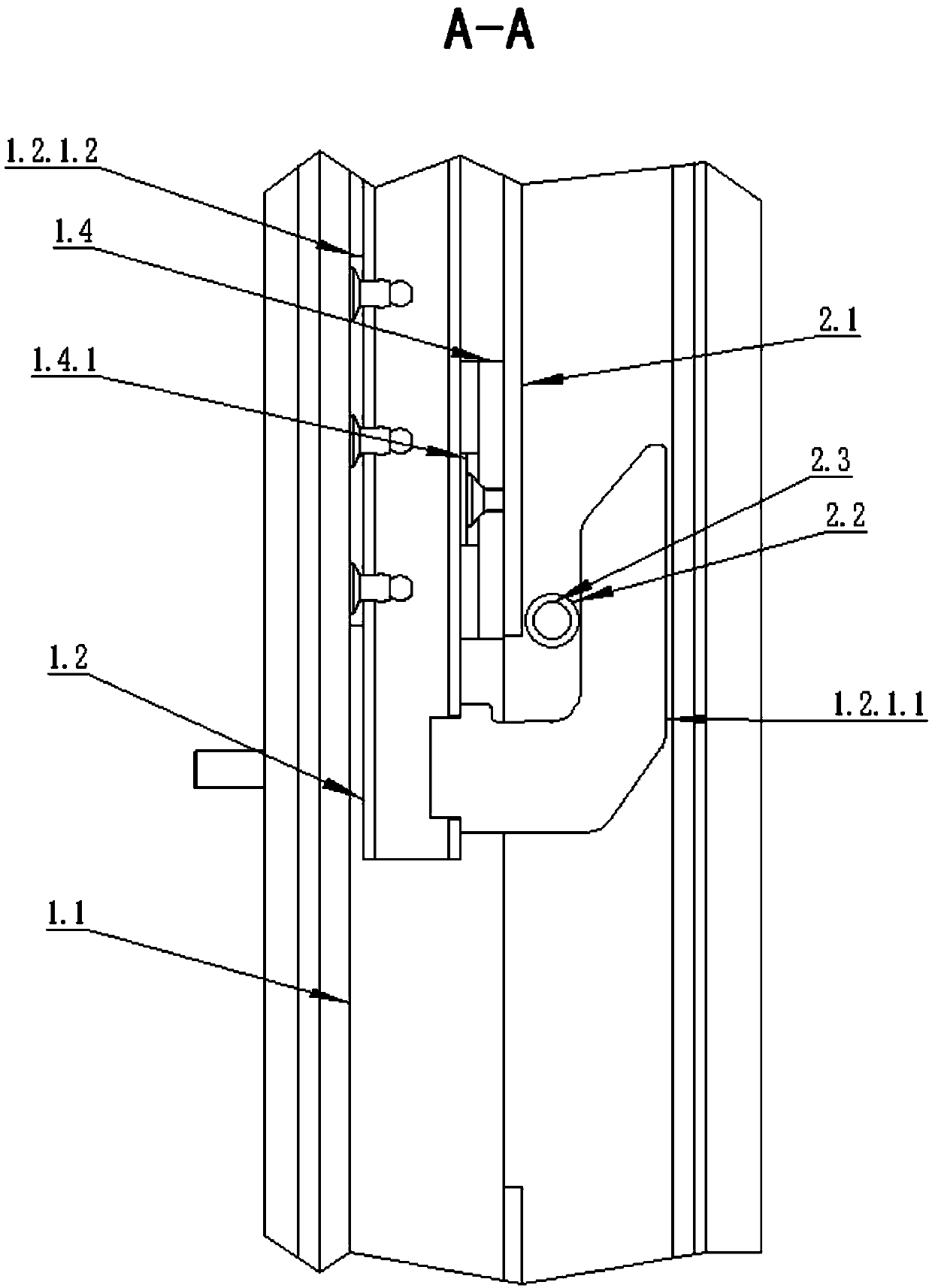

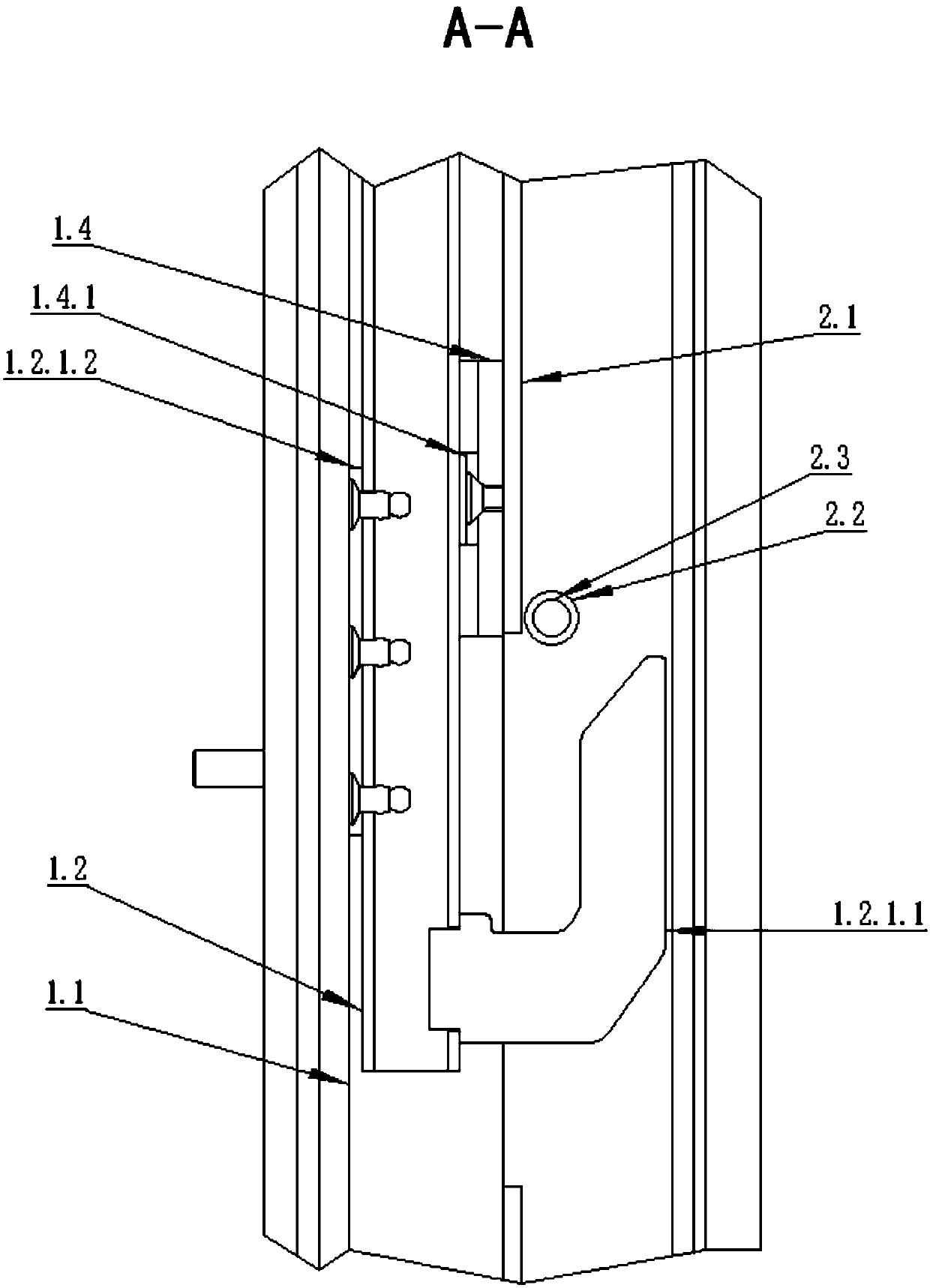

[0028]As shown in the figure: a vehicle body frame locking mechanism for a through passage, including a vehicle body frame composition 1 and a docking frame composition 2; the vehicle body frame composition 1 is the core component of the entire locking mechanism, including a vehicle body frame 1.1, Connecting rod composition 1.2, body frame sealing strip 1.3, guide seat 1.4, positioning pin 1.5, handle composition 1.6, base composition 1.7, mounting bolts 1.8, combined gasket 1.9 and body fasteners 1.10, body frame composition 1 passed The car body fastener 1.10 is pre-fixed on the end face of the car body; the car body frame 1.1 provides an installation platform for the locking mechanism, and the whole is made of small-section aluminum profiles; the connecting rod component 1.2 is the locking mechanism The main body is installed in the body frame 1.1; the body frame sealing strip 1.3 is installed on the outside of the body frame 1.1 to provide sealing for the through passage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com