An amphibious motor for mining

An amphibious motor and mining technology, applied in the field of mining power equipment, can solve the problems of low reliability of submersible pumps, frequent start-up failures, difficult maintenance, etc., so as to shorten the accident downtime, avoid mine flooding, and avoid vicious accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

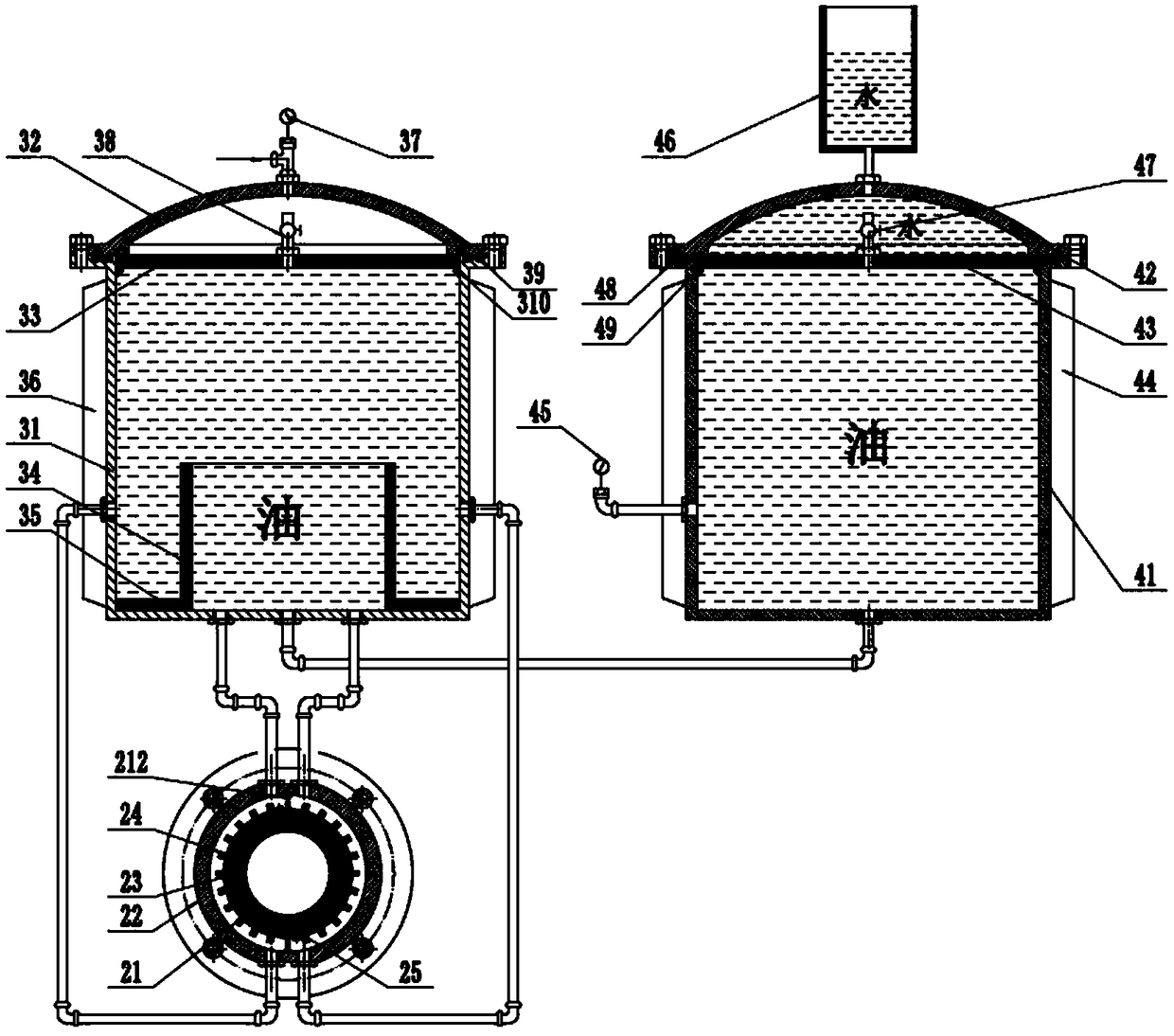

[0027] Such as Figure 1-4 As shown, the present embodiment provides a mine amphibious motor, including a motor body 1, the motor body 1 adopts a KQSL-P type mine motor, or other motors; the motor body 1 includes an outer shell and an inner shell, and the inner shell Installed in the outer shell, the two share a front end cover, the rotor cavity of the inner shell is provided with a stator 11, a rotor 12 and a power rotating shaft 13, the rotor 12 is installed in the inner shell through the power rotating shaft 13, and is located on the stator 11 In the cavity of the power rotating shaft 13, the output end of the power rotating shaft 13 is connected with the front end cover of the inner casing through a rotating bearing, and extends out of the front end cover; a junction box 14 is also arranged on the inner casing.

[0028] In this implementation, the mining amphibious motor also includes an air-water pressure self-balancing sealing device. The air-water pressure self-balancin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com