Structure and realization method of an anti-suckback self-radiating lamp

A self-dissipating and anti-suckback technology, which is applied in lighting and heating equipment, air-proof/waterproof devices, cooling/heating devices of lighting devices, etc. Simultaneous compliance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

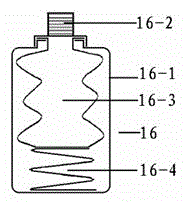

[0018] Such as Figure 1 to Figure 7 As shown, an anti-reflective self-radiating lamp structure includes sealed tempered glass 1, sealed tempered glass rubber part 2, tempered glass metal cover 3, lamp shell 5, light source lens or reflector 6 and LED light source installed Or the control circuit board 7 and the light source driver 13 of the lamp 8 of the traditional light source, and also include the insulating heat-conducting oil expansion rubber part 10, the insulating heat-conducting oil expansion rubber part locking the outer wire lock nut 11, the wire-passing sealing lock nut 12, the insulating heat-conducting oil 15. An oil tank 16 attached to the expansion of insulating heat-conducting oil.

[0019] A middle hole 5-1 and two screw holes 5-2 are respectively provided on the inner bottom surface of the cavity of the lamp housing 5, and a ring of protrusions 5-3 with internal threads are arranged on the outer bottom surface of the cavity.

[0020] The insulating and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com