A low electrical noise board-to-board connector

A noise board and connector technology, applied in the connection, connecting parts, protective grounding/shielding devices, circuits, etc., can solve the problems of long current transmission path, large electrical noise loss, etc., to reduce loss, improve isolation, shorten the Effects of ground paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

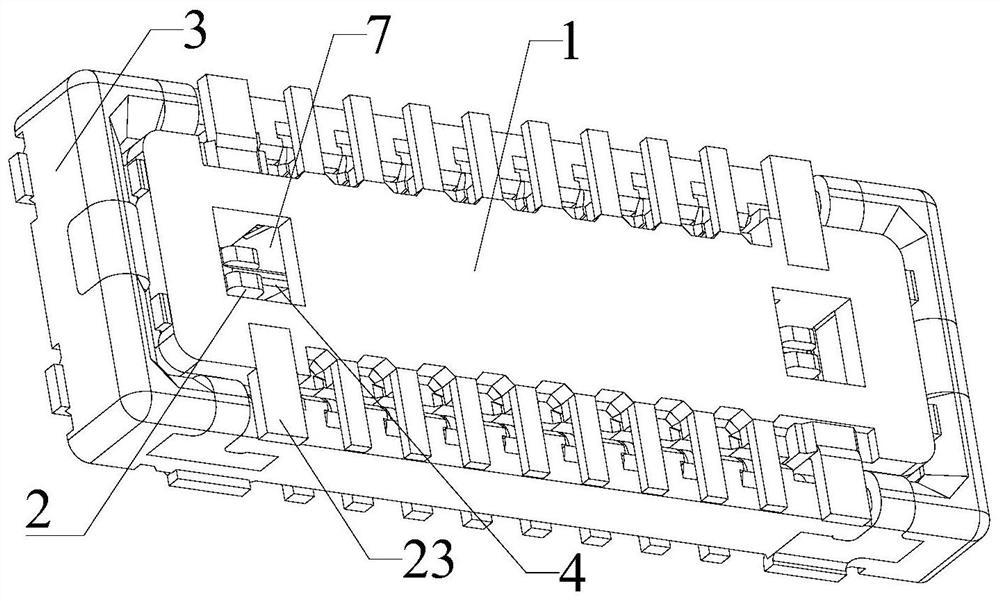

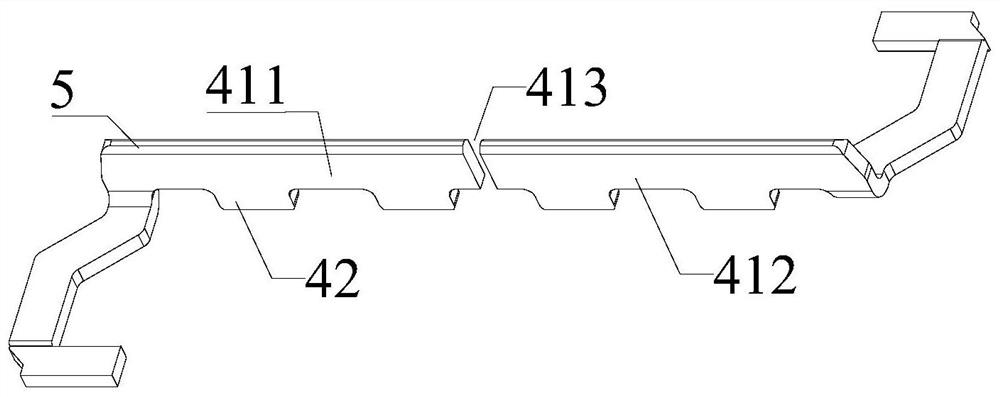

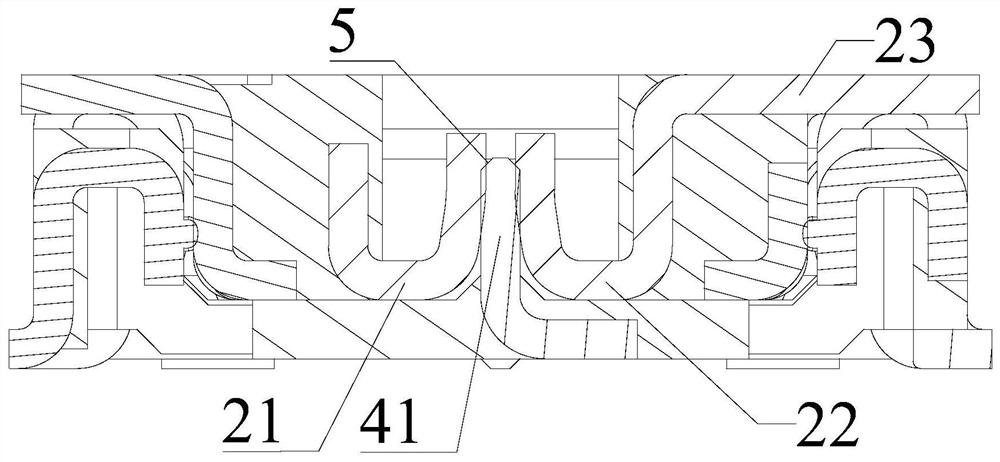

[0048] Please refer to Figure 1 to Figure 5 , Embodiment 1 of the present invention is: a low electrical noise board-to-board connector, comprising a male seat 1 and a female seat 3, the male seat 1 is provided with a first grounding pin 2, and the female seat 3 is provided with a first grounding pin 2 A second grounding pin 4 matched with a grounding pin 2, two rows of female terminals are arranged on the female base 3, the second grounding pin 4 includes a central spacer 41 and at least one grounding portion 42, the central spacer The sheet 41 is located in the area between the two rows of the female terminals, and the bottom end of the central spacer 41 extends away from the male seat 1 and is exposed on the bottom surface of the female seat 3 to form the grounding portion 42 . Preferably, the central spacer 41 is a conductive metal sheet.

[0049] Specifically, the length direction of the central spacer 41 is consistent with the length direction of the female seat 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com