Optical component surface defect detection method based on spectral estimation and electron spectroscopic technology

A technology for optical components and defects, applied in the field of surface defect detection of optical components, can solve the problems of neglecting detection efficiency, high cost, and concealment of details of optical components, so as to reduce costs, use high efficiency, and improve defect detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] The discretization of the reflection spectrum r of the embodiment is expressed as a matrix, and is discretized according to the wavelength interval of 5nm:

[0078] v=[v r v g v b ] T =Ar=A[r(λ 1 ) r(λ 2 )...r(λ n )] T

[0079] =A[r(400) r(405)...r(700)] T

[0080] Among them, A represents the system matrix, which represents the characteristics of the entire detection system.

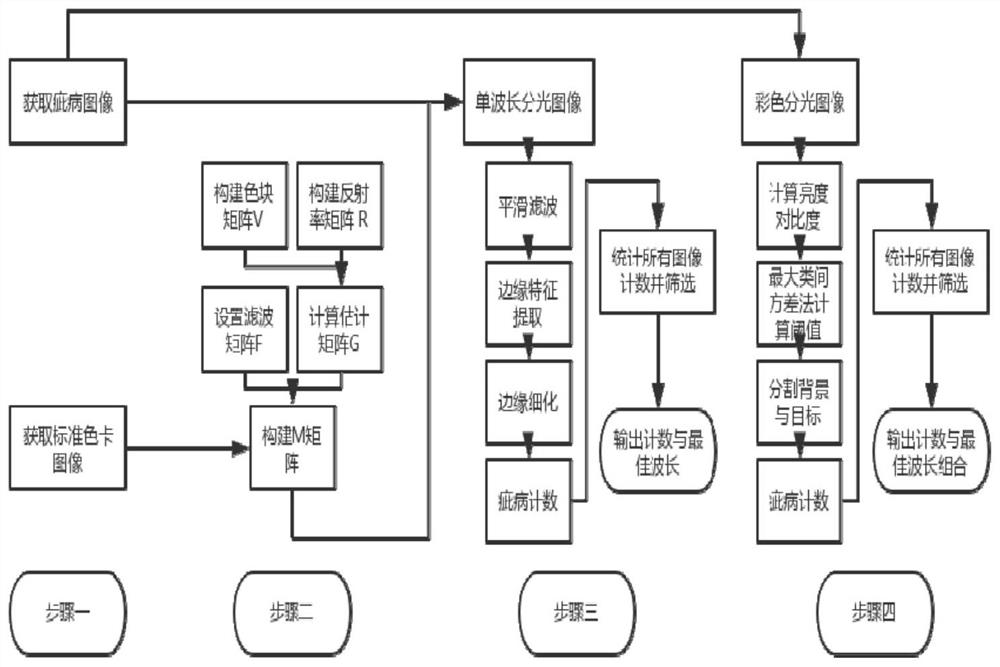

[0081] The specific program implementation process is as follows: figure 1 as shown ( figure 1 Using V and R to construct G is step 1 (1), using F and G to construct M and calculating the filtered image is step 2 (2)),

[0082] Wherein the color defect image is obtained by using a color camera CCD to shoot the surface of the optical element; the color block matrix V is constructed by a standard color card value, and the embodiment adopts a 24-color color card, and V is a matrix of 3x24 dimensions (3 is three components of RGB) ;Aiming at 24 color cards, each color has a different r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com