Gas spring reinforcement plate for back door

A gas spring, back door technology, used in doors, vehicle parts, transportation and packaging, etc., can solve the problems of sheet metal and solder joint stress concentration, small number of solder joints, small bonding surface, etc., to achieve local stress dispersion , The effect of improving stiffness and strength bearing capacity and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

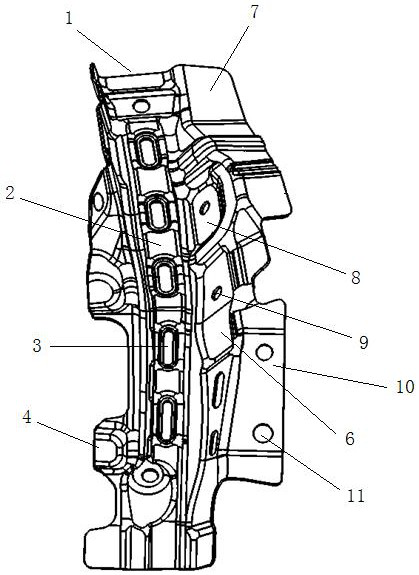

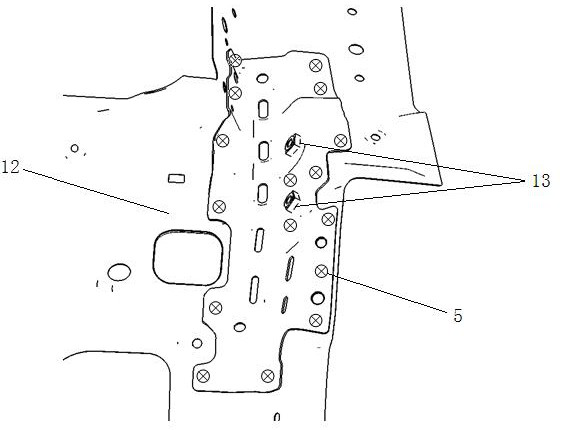

[0026] Such as figure 1 , 2 As shown, the rear door gas spring reinforcing plate of the present invention is a strip type that is stamped as a whole, including a base surface 1 on the left, and a T-shaped reinforcing rib 2 is provided on the base surface 1, and the T-shaped reinforcing rib 2 There are a plurality of weight-reducing holes 3 with bosses in the longitudinal direction, and six welding contact pins 4 of different shapes extend from the base surface 1 to the left end, and each welding contact pin 4 is connected to the inner panel of the back door through a welding spot 5 ; The right part is bent upwardly relative to the base surface 1 body into a step shape, including the step surface 7, and the gas spring installation surface 6 between the base surface 1 and the step surface 7, the gas spring installation surface 6 is meniscus-shaped The structure is inclined between the base surface 1 and the step surface 7. The gas spring installation surface 6 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com