Method of reducing tin soldering voidage between COB (chip on board) and heat-dissipation base

A technology of heat dissipation base and void rate, which is applied to tin feeding devices, welding equipment, auxiliary devices, etc., can solve the problems of inability to further improve the heat dissipation efficiency of the whole lamp and the high void rate of soldering, so as to ensure the industrialization promotion and improve the success. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

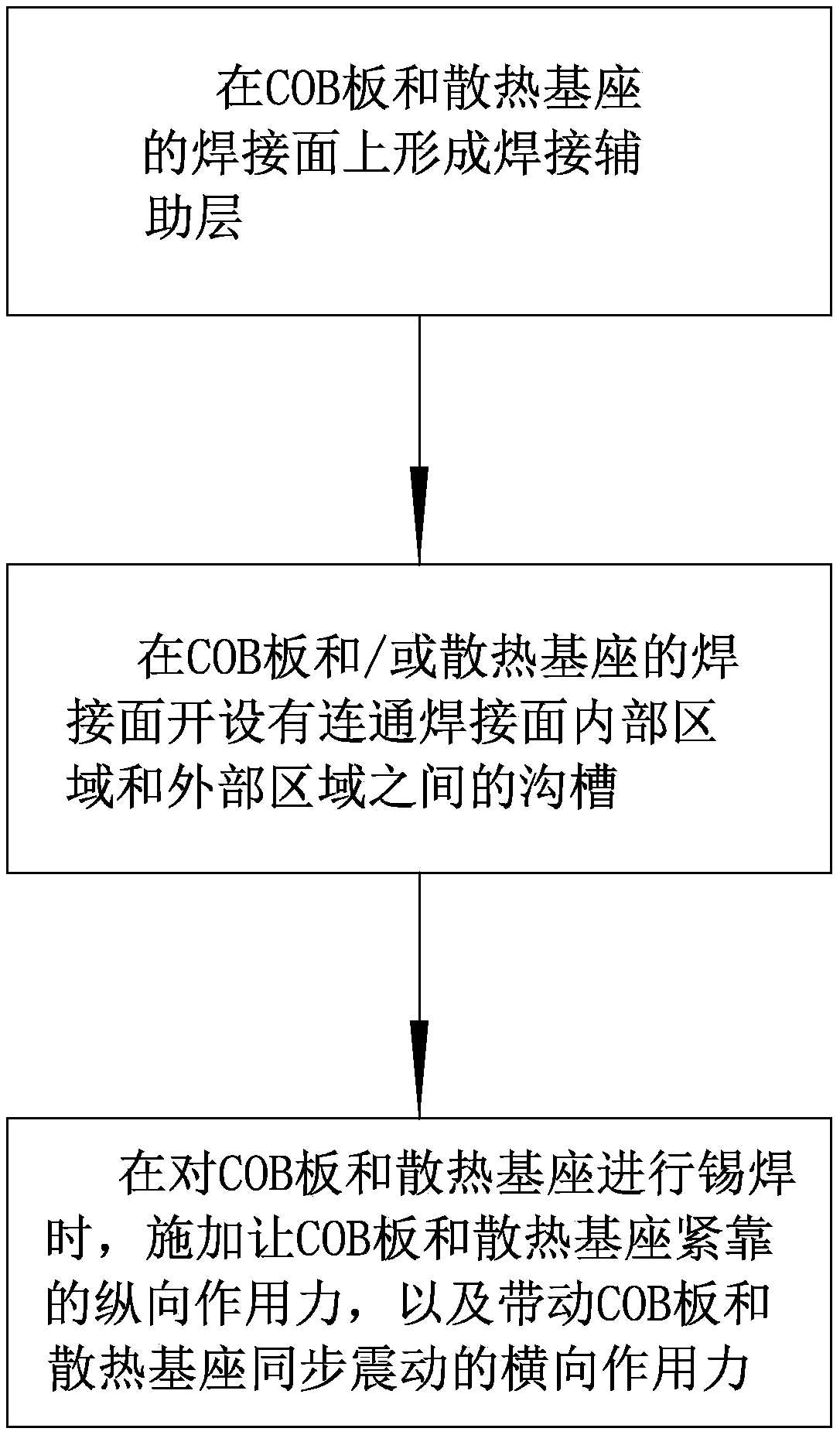

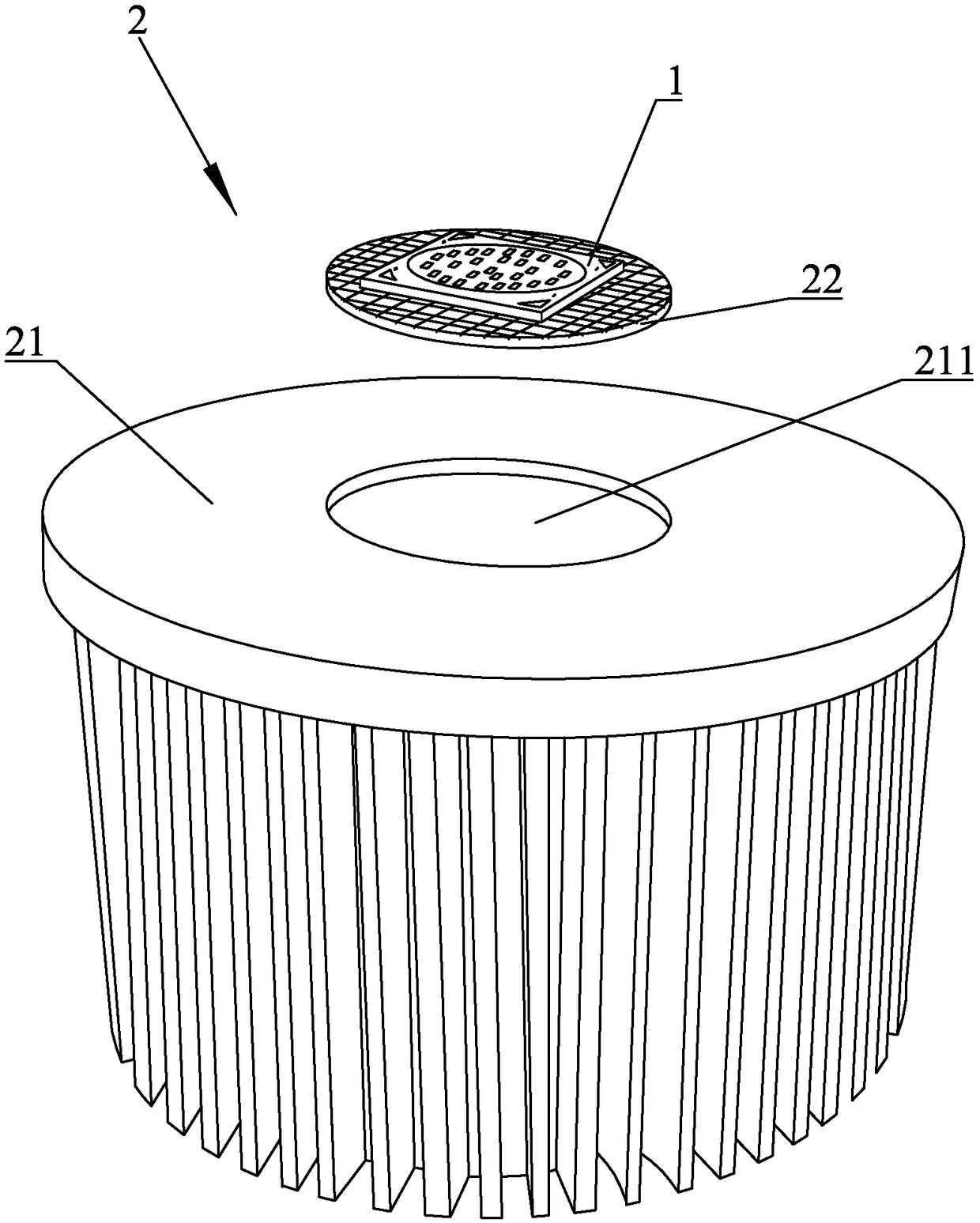

[0031] Such as Figure 2 to Figure 8 As shown, the present invention relates to a method for reducing the solder void rate between the COB board 1 and the heat dissipation base 2, comprising the following steps:

[0032] ① Form a welding auxiliary layer on the welding surface of the heat dissipation base 2; the welding auxiliary layer is to ensure that the melted solder paste will not cause desoldering due to the excessive thermal conductivity of the COB board 1 or the heat dissipation base 2; In this embodiment, the welding auxiliary layer is selected as a nickel-plated layer;

[0033] ② On the welding surface of the COB board 1 and / or the heat dissipation base 2, there is a groove connecting the inner area and the outer area of the welding surface, the depth of the groove is greater than or equal to the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com