Automatic fire extinguishing system for multi-bin cotton mixing machine

An automatic fire extinguishing system, multi-silo cotton blending technology, applied in fire rescue and other directions, can solve the problems of long rescue time, affecting production safety, unable to identify the fire location, etc., to achieve the effect of reasonable layout and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

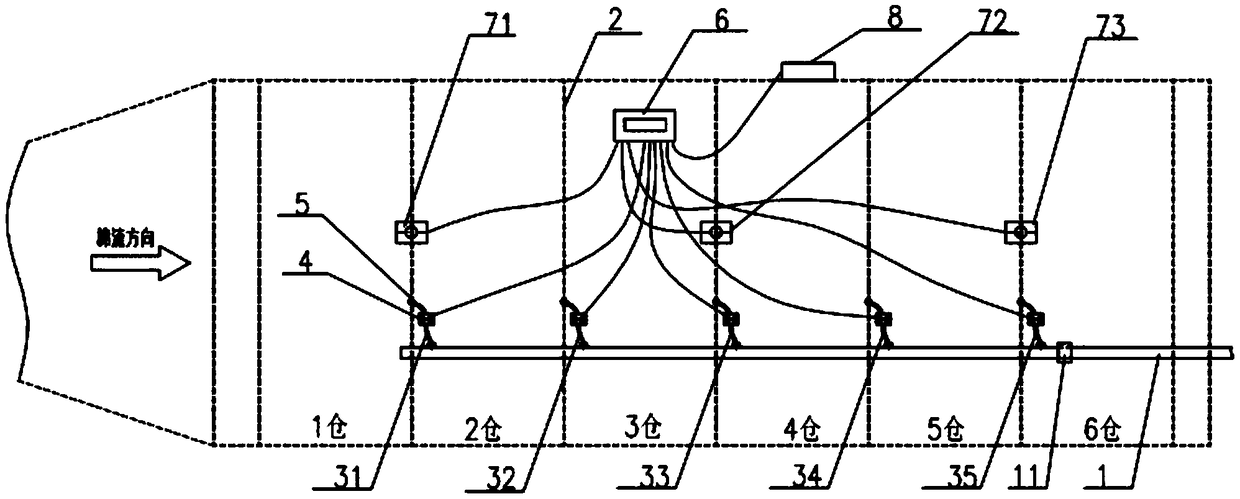

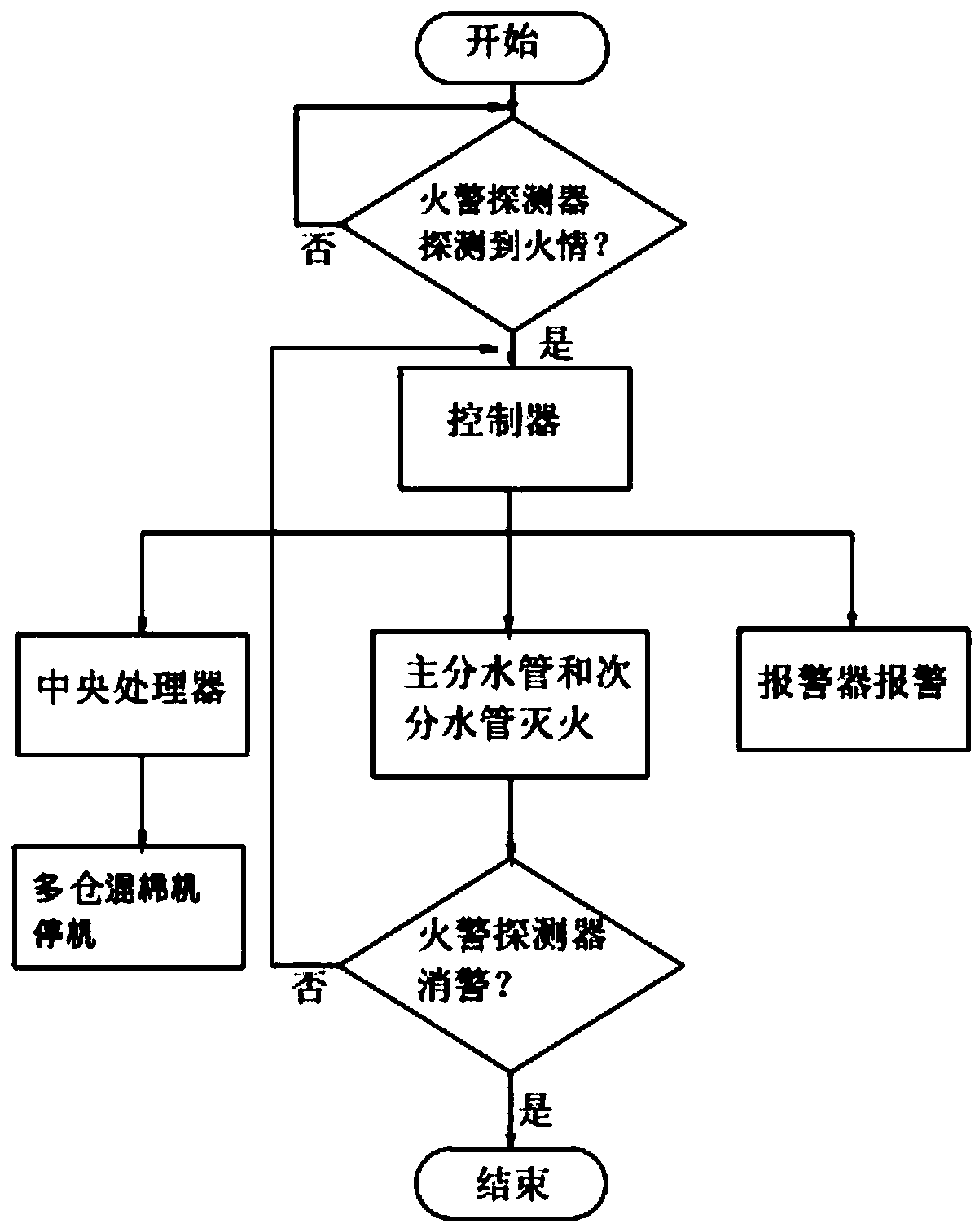

[0014] Such as figure 1 with figure 2 As shown, an automatic fire extinguishing system for a multi-compartment cotton blending machine, the number of compartments of the multi-compartment cotton blending machine is 6 compartments, which are named as 1 compartment, 2 compartments, 3 compartments, 4 compartments, 5 compartments, and 6 compartments according to the direction of cotton flow. warehouse, the automatic fire extinguishing system includes a main water pipe 1 and a control system, the main water pipe 1 is arranged on the roof of a multi-compartment warehouse, and the main water pipe 1 is provided with a water distribution pipe adjacent to each multi-compartment partition board 2, according to the cotton flow direction Water distribution pipe Ⅰ31, water distribution pipe Ⅱ32, water distribution pipe Ⅲ33, water distribution pipe Ⅳ34, water distribution pipe Ⅴ35,

[0015] The water distribution pipe is provided with a pulse electromagnetic valve 4, and the water outlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com