Support for maxillary sinus floor elevation space maintenance and use method of support

A pillar and maxillary sinus technology, applied in the field of pillars for maintaining the lifting space of the maxillary sinus floor, can solve problems such as difficulty in maintaining the lifting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

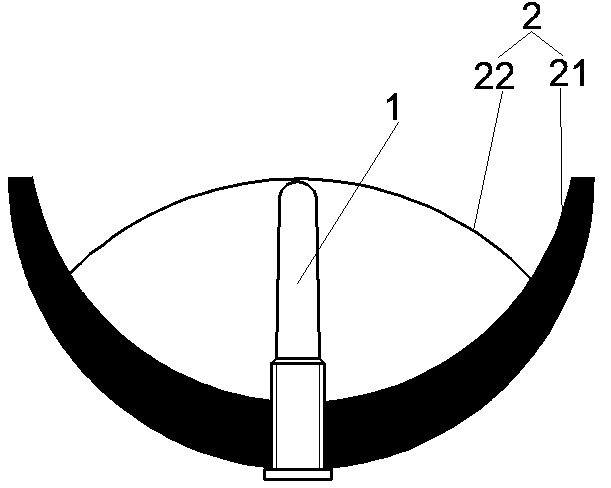

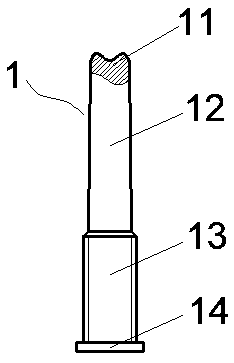

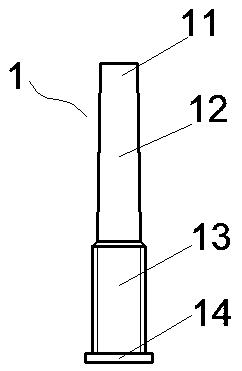

[0031] Such as figure 1 , 2 As shown, the present invention provides a pillar 1 for maintaining the maxillary sinus floor lifting space, the cross-section of the pillar is circular, and the cross-sectional diameter at any position is not greater than the cross-sectional diameter at the lower end position, so that it is easy to enter the upper jaw sinus. From top to bottom, the pillars are blunt part 11, smooth section 12, threaded section 13 and protruding section 14. Both smooth section 12 and threaded section 13 can be cylindrical or conical, including but not limited to the following situations: 1) Both the smooth section 12 and the threaded section 13 are cylindrical; 2) The smooth section 12 and the threaded section 13 are both conical; 3) The smooth section 12 is cylindrical, and the threaded section 13 is conical; 4) The smooth section 12 is conical , Thread segment 13 is cylindrical (such as figure 1 , 4 , 5). In either case, the precondition that the cross-sectio...

Embodiment 2

[0043] Such as Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is that the upper surface of the blunt portion of the pillar is a concave arc surface in the middle. Several situations listed in Example 1 are used in the same way.

Embodiment 3

[0045] Such as Figure 5 As shown, the difference between embodiment 3 and embodiment 1 is that the upper surface of the blunt part of the pillar is a plane, and the rest of the structure is the same as that of embodiment 1, and the shapes of the smooth section 12 and the threaded section 13 can also be listed in embodiment 1. In several situations, the method of use is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com