Method for protecting a rotation separator from icing, and rotation separator

一种旋转分离器、转子的技术,应用在离心机、机器/发动机、发动机的润滑等方向,能够解决旋转分离器穿流、旋转分离器功率受损、转子的轴承结冰等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

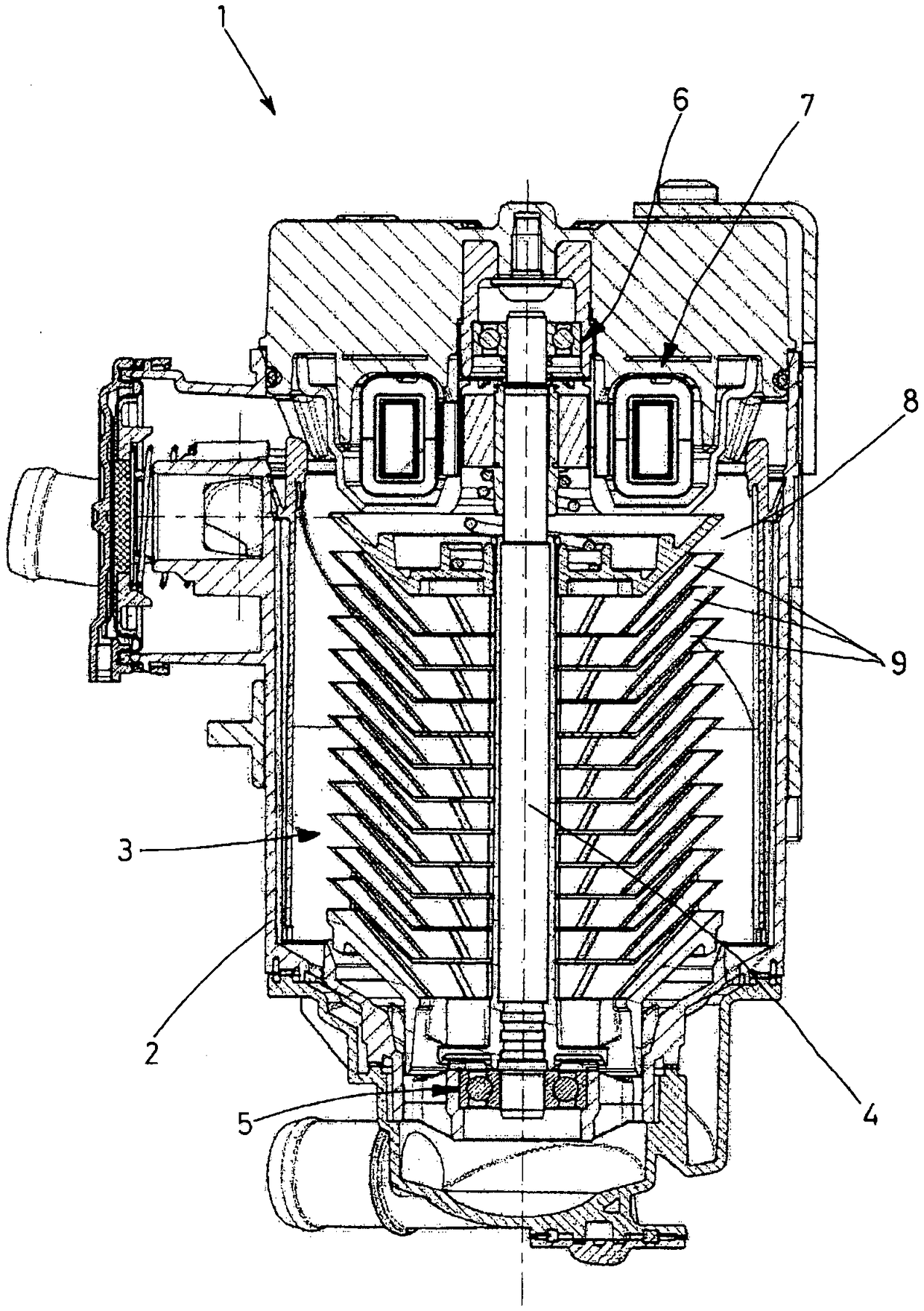

[0026] exist figure 1 In , a rotary separator is designated as a whole by 1, which is designed as a so-called disc separator. The rotary separator 1 has a housing 2 in which a rotor 3 is mounted rotatably about a vertical axis 4 . To this end, the shaft 4 is guided in a lower foot bearing 5 and an upper head bearing 6 . Below said head bearing 6 there is an electric drive unit 7 which directly adjoins an interior space 8 in which there are a plurality of cavity-shaped separation surfaces driven in rotation by means of the shaft 4 which correspond to The land is called Disk 9. The drive unit 7 has a coil which extends concentrically around the shaft 4 .

[0027] Between the disks 9 there remain surface gaps, which can be reduced, for example, to dimensions of less than 0.5 mm, and which are provided with gaps of small cross-sectional size for sealing between the raw side and the clean side Also known as gap seals. Furthermore, it cannot be ruled out that the foot bearing 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com