Vacuum assist toilet trap

A flush toilet and vacuum-assisted technology, applied in water supply devices, flush toilets, flushing equipment with water tanks, etc., can solve problems such as not being too small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

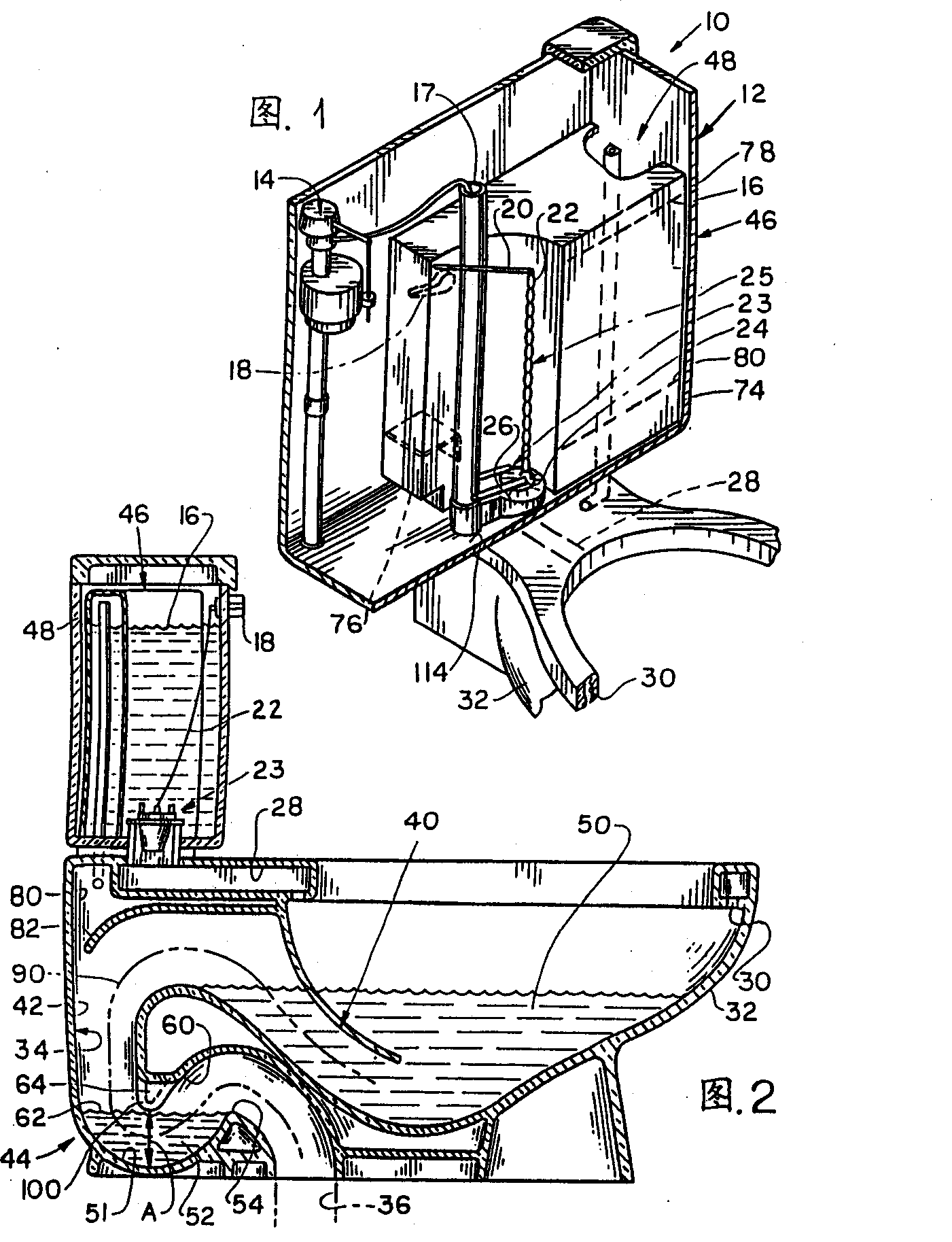

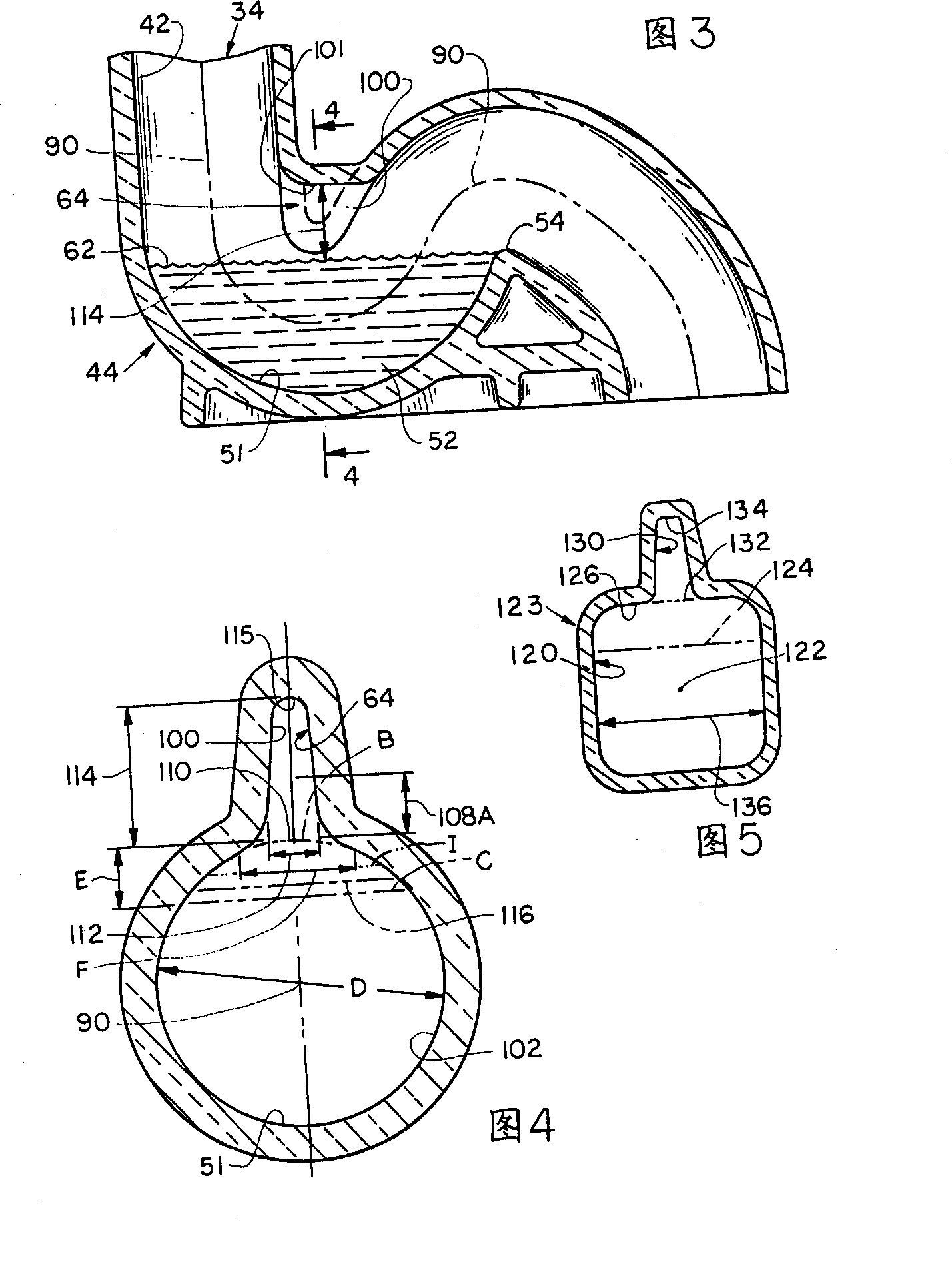

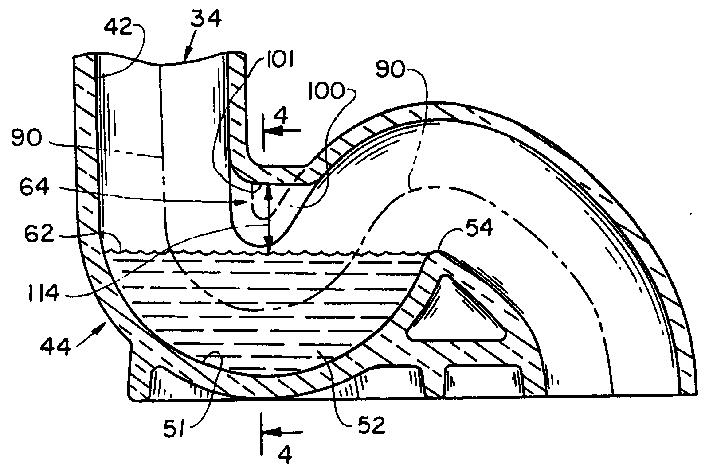

[0028] Figure 1 depicts a vacuum assisted toilet 10 which includes a tank or sink 12 which holds a conventional inlet valve 14 . The water inlet valve distributes water to the water tank until the water level reaches a predetermined high water level 16, and it also distributes water through a refill pipe 17 to the toilet. When a handle 18 of the flushing valve assembly 25 is pressed by hand to rotate around the axis, a bar 20 and a chain 22 are lifted to operate a drain valve 23 by rotating a drain valve assembly 24 to make it This is done by lifting away from a seat 26 of the discharge valve which faces mainly upwards. The water in the water tank flows quickly through the seat 26 and a water channel 28 and through the toilet side orifice 30 and enters the toilet 32 (the toilet seat is not shown). As shown in Figure 2, the toilet 32 has a toilet outlet 34 which discharges water and waste into a sewer 36 which is connected to the sewage system.

[0029]The toilet outlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com