Magnetic tile, motor rotor, motor

A technology for motor rotors and magnetic tiles, applied in the fields of motor rotors, motors, and magnetic tiles, can solve problems such as torque fluctuations, achieve the effects of reducing torque fluctuations, eliminating torque fluctuations, and benefiting noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

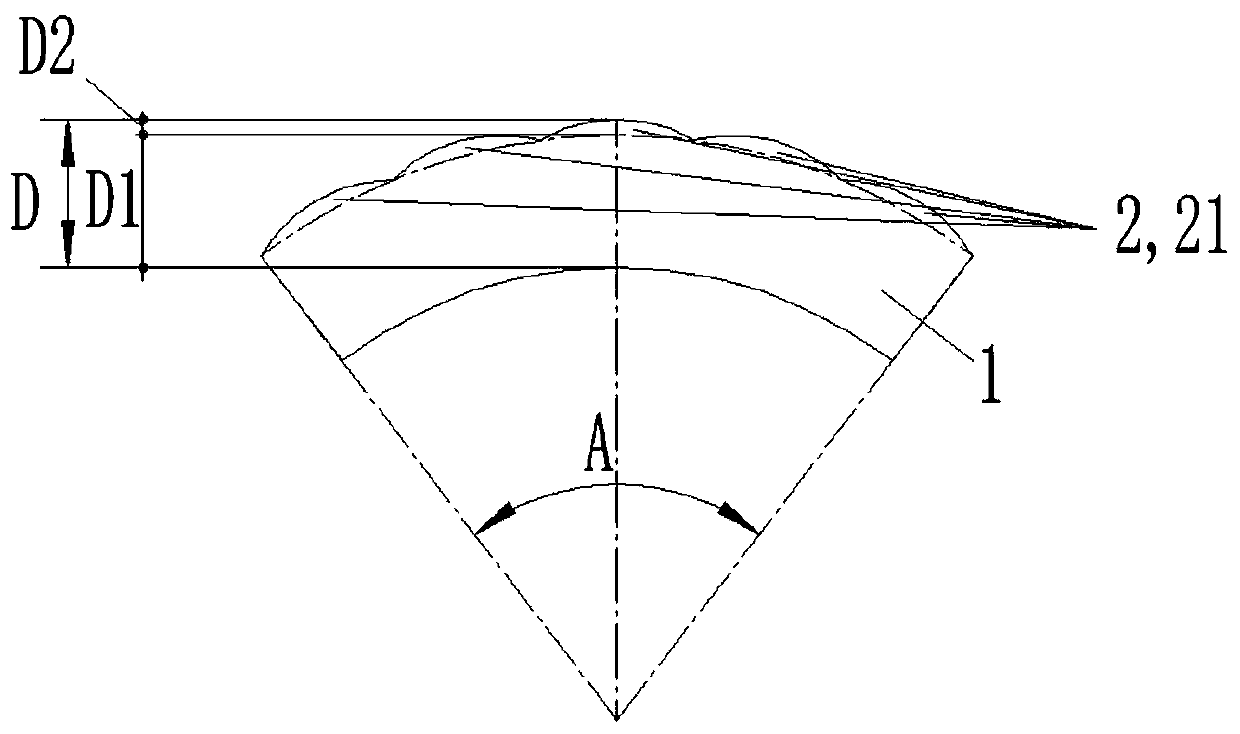

[0018] see figure 1 As shown, according to an embodiment of the present invention, a magnetic tile is provided, including a back EMF fundamental wave generation part 1, a back EMF harmonic generation part 2, and the back EMF harmonic generation part 2 is in the position of the back EMF fundamental wave generation radial direction outside of part 1. In this technical solution, since the magnetic tile has a back EMF harmonic generating part 2, the harmonic generated by the back EMF harmonic generating part 2 is synthesized with the fundamental wave of the winding current, and the synthesized output torque can offset the cogging torque A certain harmonic component can reduce torque fluctuations, which is beneficial to the reduction of motor noise. Under the condition that the back EMF harmonic generation part 2 is set reasonably, it can completely offset the cogging torque in theory, so as to ensure the complete elimination of the torque. Moment fluctuations.

[0019] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com